Edge grinding system and method for flat plate glass

A flat glass and edging technology, which is applied in the direction of grinding machines, grinding racks, grinding beds, etc., can solve the problems of uneven grinding of the whole edge, easy breakage, long running distance of the grinding table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

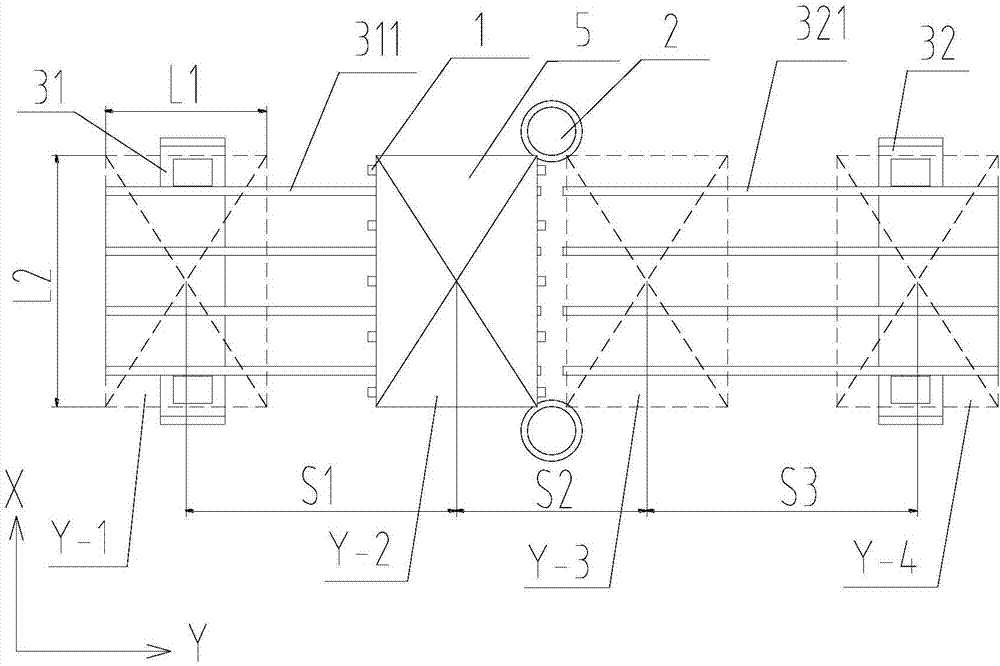

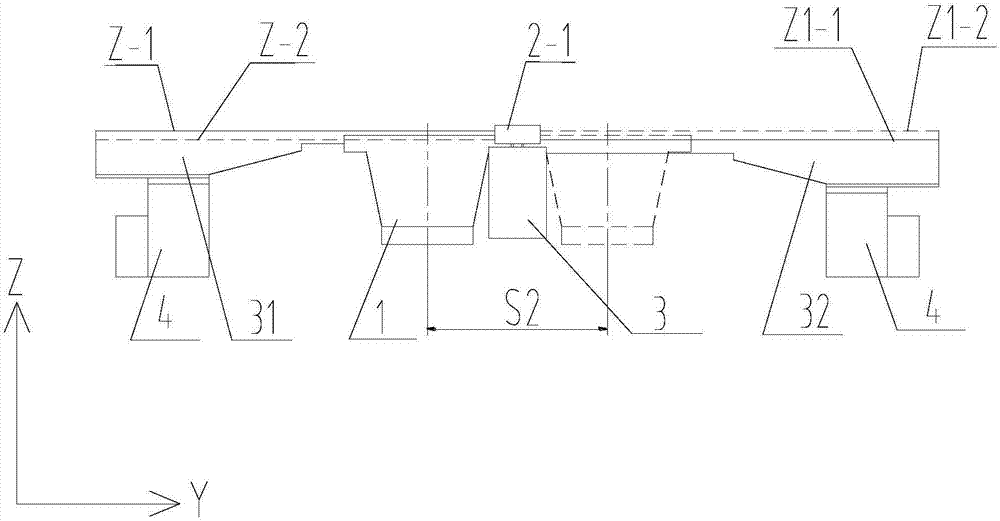

[0045] In the present invention, unless stated otherwise, the used orientation words such as "upstream and downstream" are relative to the grinding table, along the direction of the edge grinding process of the flat glass. Wherein, the X-axis direction, the Y-axis direction, and the Z-axis direction described in the specification are three-dimensional coordinate axes perpendicular to each other.

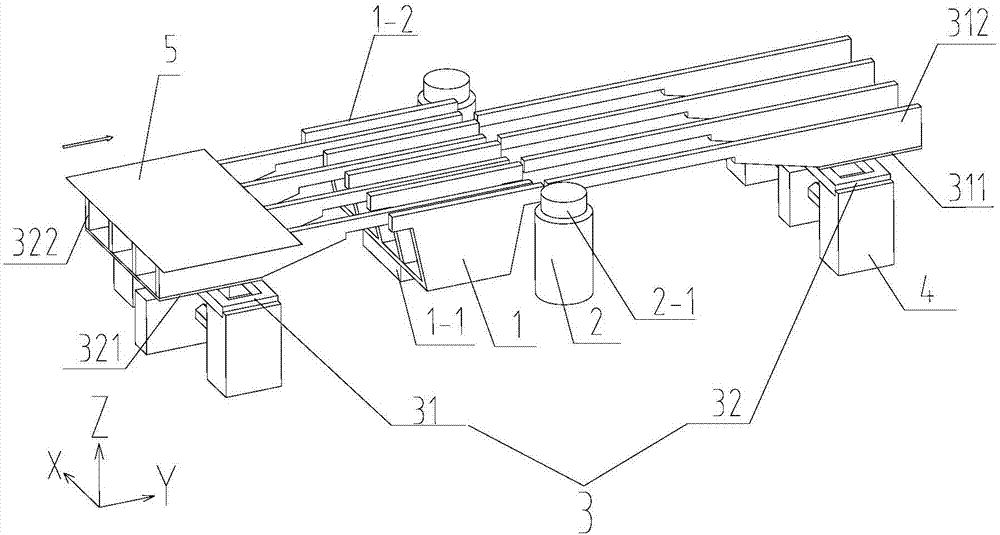

[0046] see Figure 1 to Figure 3 A flat glass edging system according to a preferred embodiment of the present invention is shown, wherein the flat glass edging system includes: a grinding table 1; at least two sets of grinding wheel devices 2, at least two sets of gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap