PbS quantum dot doped glass with broad spectrum fluorescent characteristic in femtosecond laser direct writing and preparation method thereof

A technology with femtosecond laser and fluorescence characteristics, applied in the field of PbS quantum dot doped glass and its preparation, can solve the problems of high energy consumption, high temperature of quantum dot doped glass, inability to control the spatial distribution of quantum dots, etc., to achieve luminous intensity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of femtosecond laser direct writing PbS quantum dot-doped glass with broad-spectrum fluorescence characteristics, the method is as follows:

[0027] 1) Select a suitable glass, which contains sulfur and lead, and after high-temperature heat treatment, lead sulfide quantum dots can be precipitated in the glass matrix.

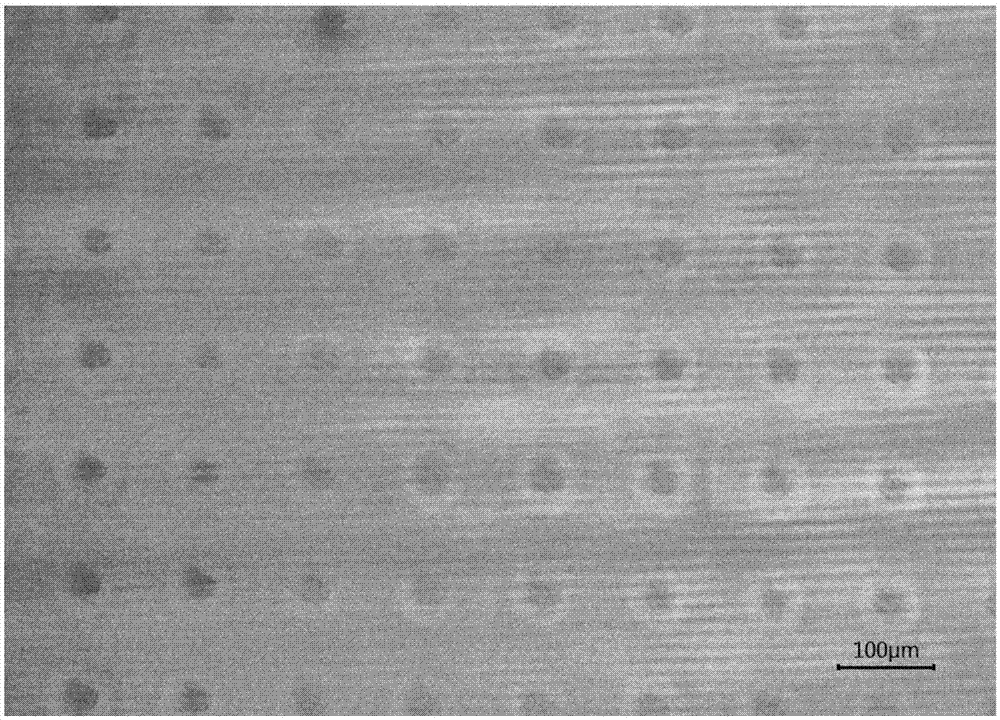

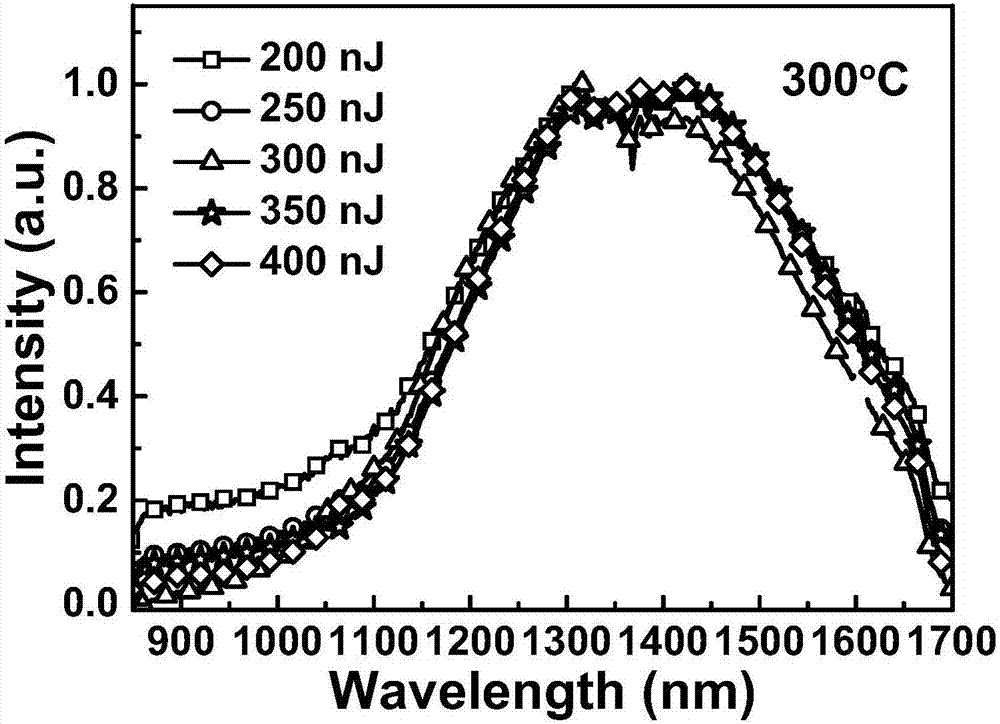

[0028] 2) Prepare the luminous area for femtosecond laser direct writing: focus the femtosecond laser on the glass in step 1), and control the displacement and processing speed through the three-dimensional processing platform, so that the femtosecond laser is focused and irradiated to write the luminous area inside the glass, The single pulse energy of the femtosecond laser is 200 to 400nJ, the repetition frequency is 1MHz, and the processing speed is 50 microns per second; then the glass is heat-treated at 300°C for 30min to obtain the light-emitting area directly written by the femtosecond laser.

[0029] After testing, the femtosecond lase...

Embodiment 2

[0033] Preparation of femtosecond laser direct writing PbS quantum dot-doped glass with broad-spectrum fluorescence characteristics, the method is as follows:

[0034] 1) Select a suitable glass, which contains sulfur and lead, and after high-temperature heat treatment, lead sulfide quantum dots can be precipitated in the glass matrix.

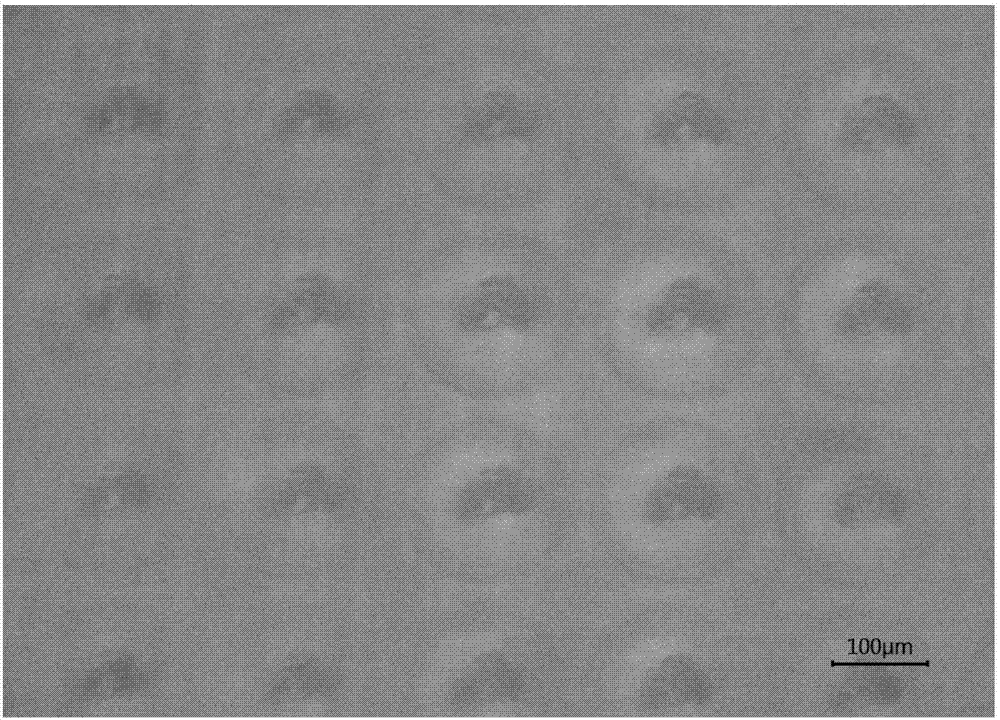

[0035] 2) Prepare the luminous area for femtosecond laser direct writing: focus the femtosecond laser on the glass in step 1), and control the displacement and processing speed through the three-dimensional processing platform, so that the femtosecond laser is focused and irradiated to write the luminous area inside the glass, Femtosecond laser single pulse energy 200nJ, repetition frequency 1MHz, processing speed 50 microns per second; then heat-treat the photoluminescent glass at 420°C, 430°C or 440°C for 10h (300°C in the figure, processed at this temperature , will not lead to the growth of quantum dots, but can eliminate the defects produ...

Embodiment 3

[0039] Preparation of femtosecond laser direct writing PbS quantum dot-doped glass with broad-spectrum fluorescence characteristics, the method is as follows:

[0040] 1) Select a suitable glass, which contains sulfur and lead, and after high-temperature heat treatment, lead sulfide quantum dots can be precipitated in the glass matrix.

[0041] 2) Prepare the luminous area for femtosecond laser direct writing: focus the femtosecond laser on the glass in step 1), and control the displacement and processing speed through the three-dimensional processing platform, so that the femtosecond laser is focused and irradiated to write the luminous area inside the glass, The femtosecond laser pulse energy is 400nJ, the repetition frequency is 1MHz, and the processing speed is 50, 200, or 400 microns per second; then, the photoluminescent glass is heat-treated at 300°C for 30 minutes to obtain the luminescent area directly written by the femtosecond laser.

[0042] After testing, the femt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com