Quadruple-sealing energy-saving aluminium alloy door window

An aluminum alloy door and window, four-sealing technology, applied to the installation of sealing devices, windows/doors, window glass, etc., can solve the problems of easy noise generation at the overlapping joints of glass bead and door and window frame leaves, small air cavity size, thermal insulation The effect is not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

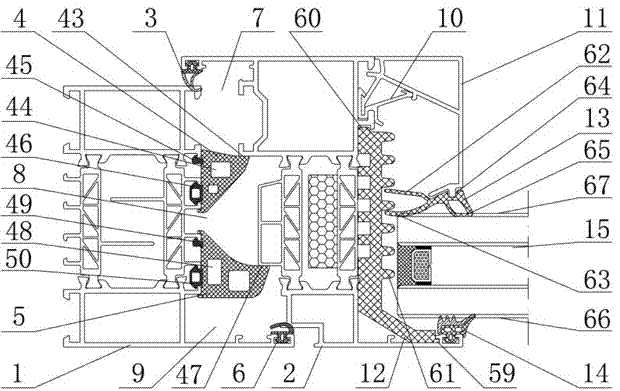

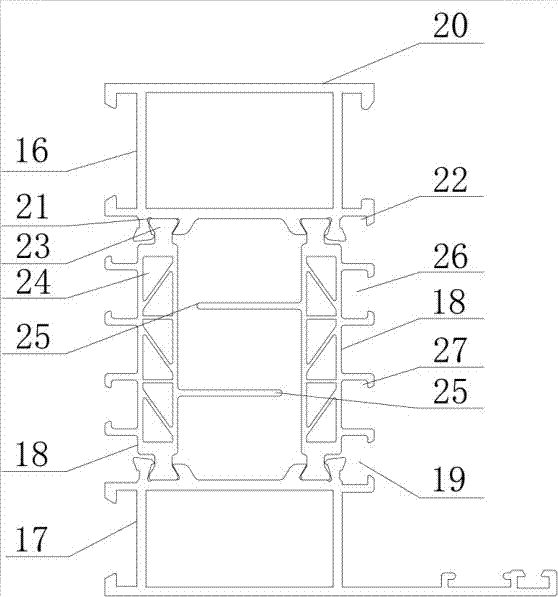

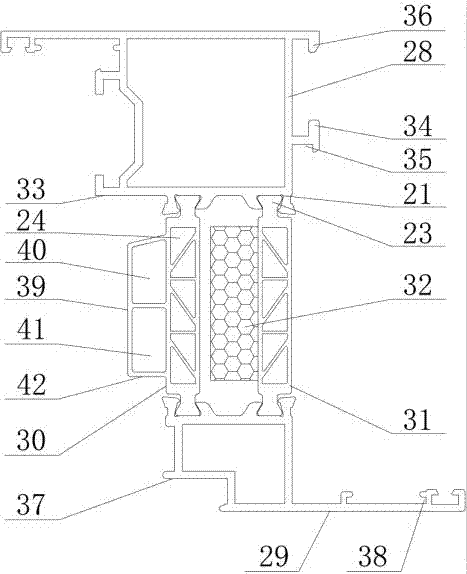

[0017]A four-seal energy-saving aluminum alloy door and window, including a door and window frame 1, a door and window leaf 2, a first sealing rubber strip 3, a second sealing rubber strip 4, a third sealing rubber strip 5, a fourth sealing rubber strip 6, and a first air cavity 7. The second air cavity 8, the third air cavity 9, the glass bead anti-vibration pad 10, the glass bead 11, the glass heat insulation pad 12, the long tail rubber strip 13 inside the glass, the rubber strip 14 outside the glass, and the insulating glass 15; its characteristics That is: the door and window frame 1 is composed of the aluminum alloy profile 16 inside the door and window frame, the aluminum alloy profile 17 outside the door and window frame, the first heat insulation strip 18, and the third card slot 19; The outer surface of the alloy profile 20, the first clamping groove 21, the first hook groove 22; the first clamping head 23, the first cavity 24, the partition 25, the second clamping gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com