Displacement Control Unit

A technology of control unit and control cylinder, which is applied in the direction of engine components, functional valve types, transportation and packaging, etc., can solve the problems of low control force energy level, large volume, unsafe, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

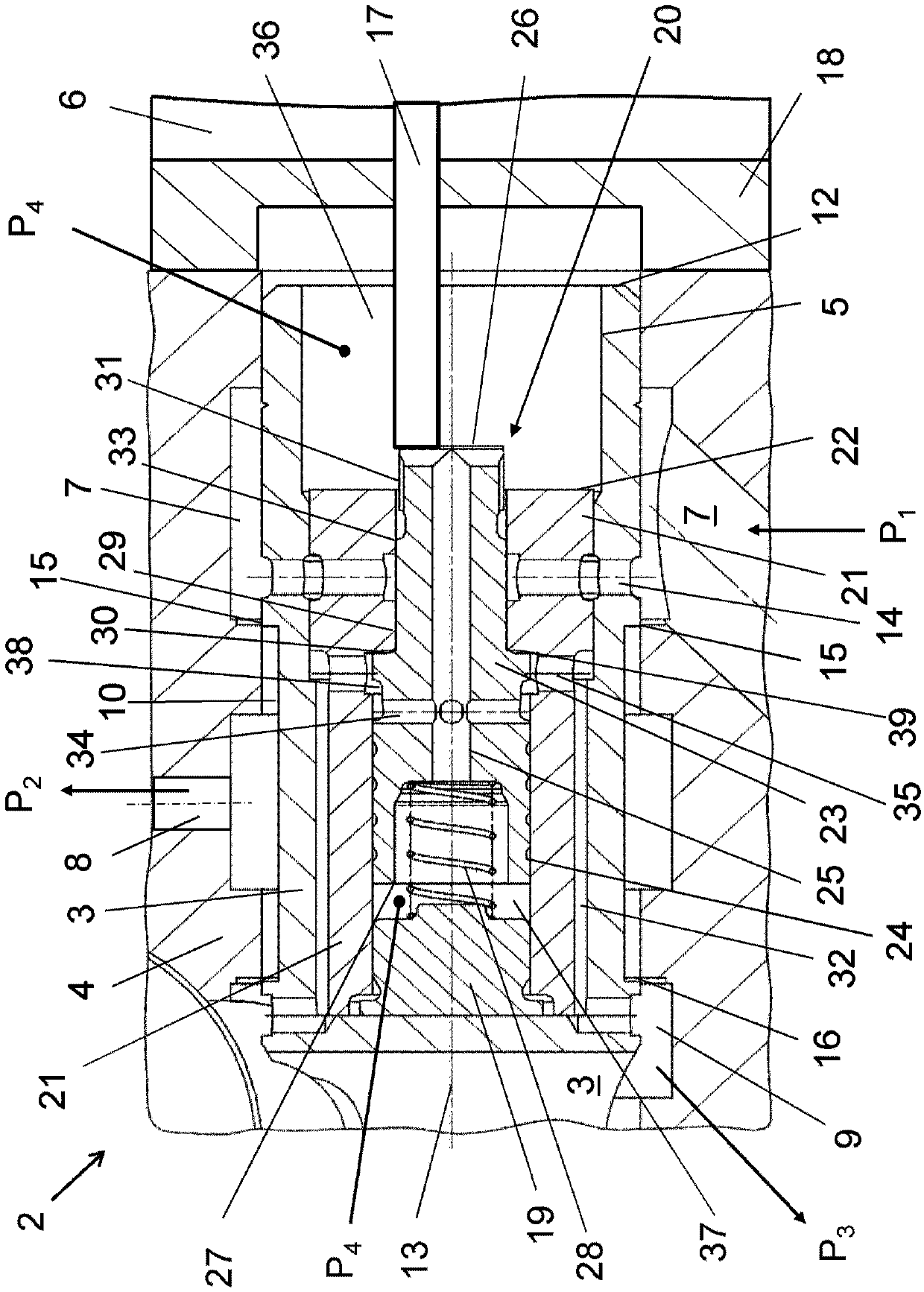

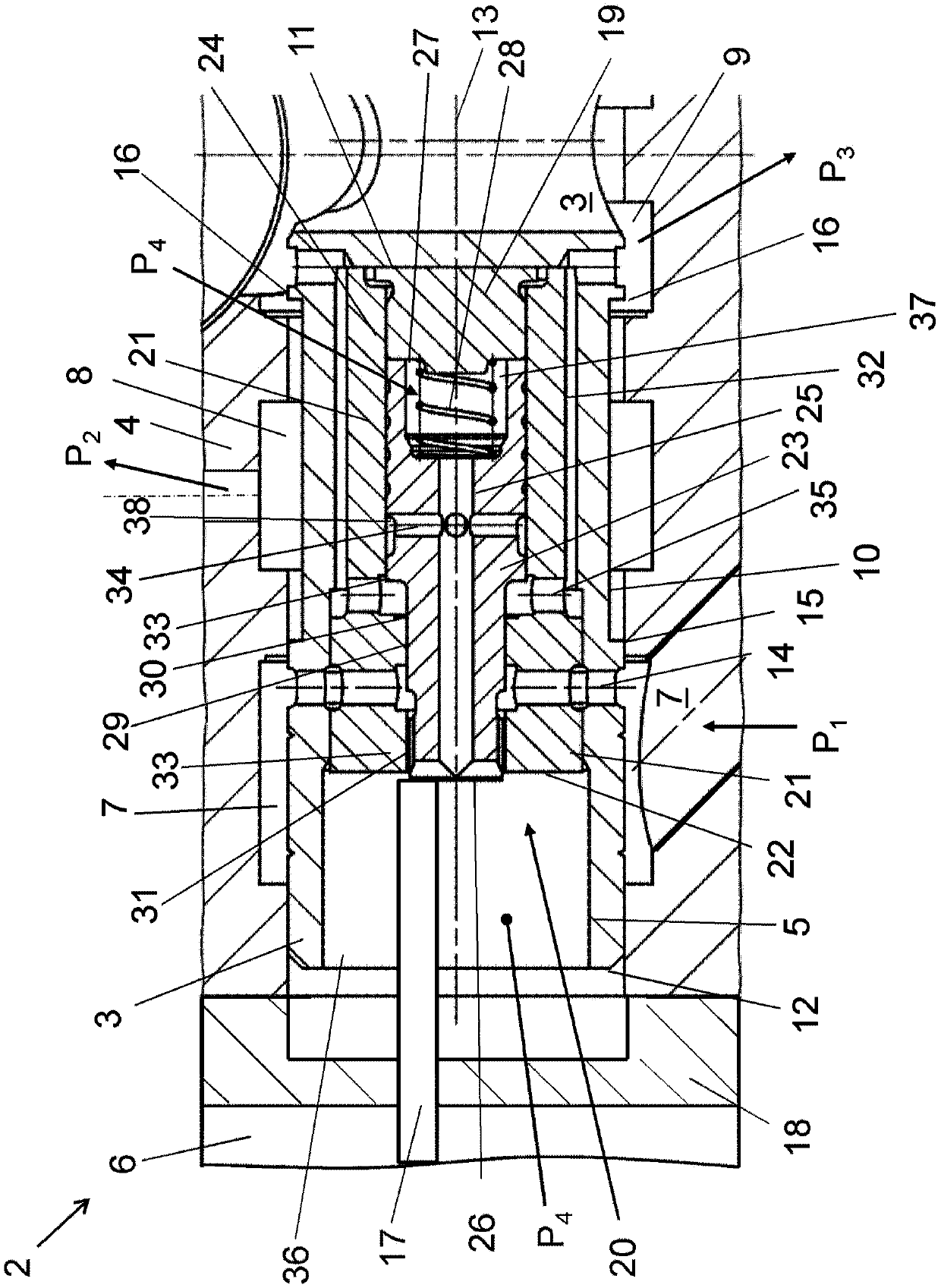

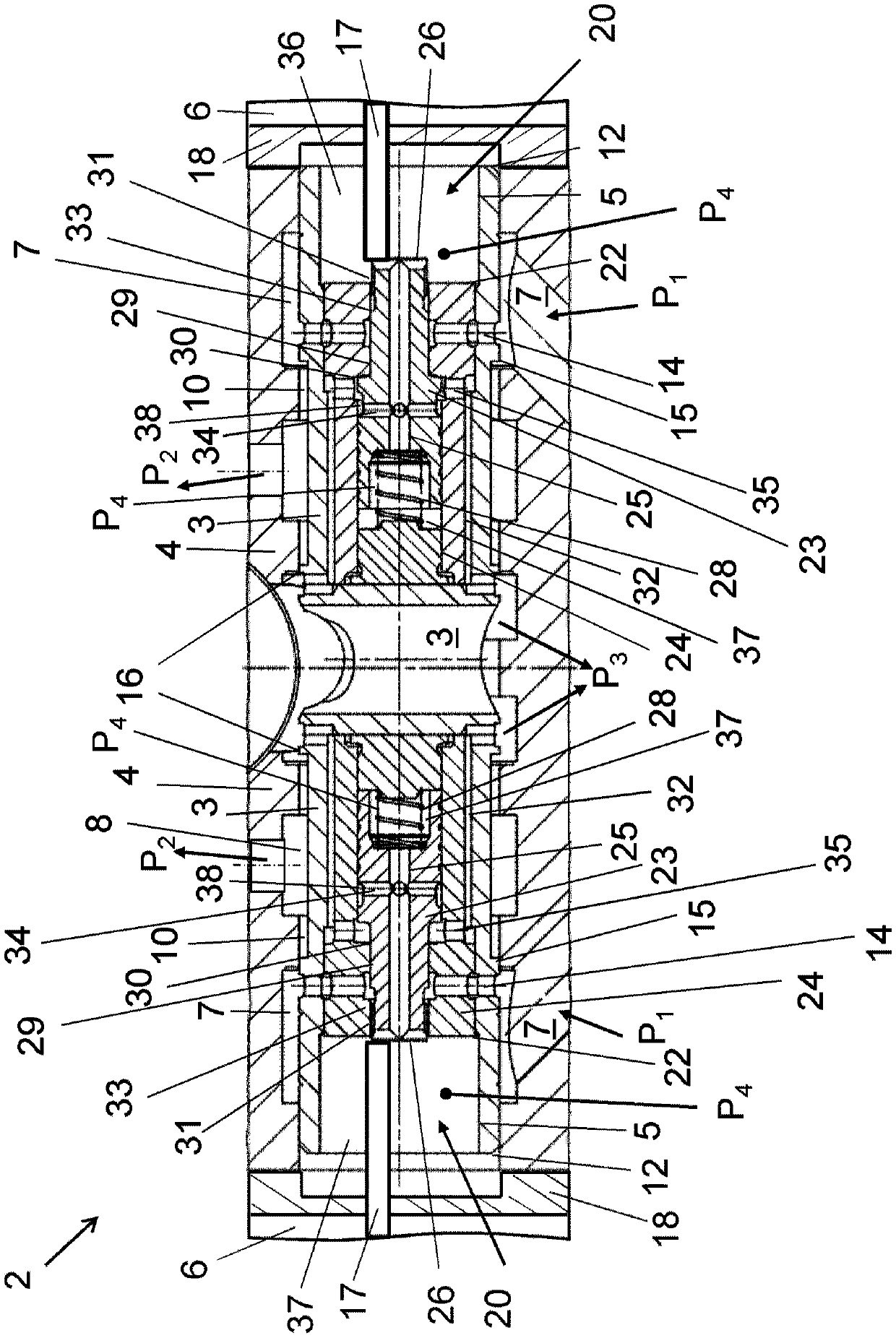

[0022] figure 1 A partial cross section of an embodiment of the control unit 2 according to the invention is shown. Shown is the right side of the substantially symmetrical control unit 2, where the control unit 2 includes a common control cylinder 4, and a movable and substantially symmetrical control piston 3 is provided in the cylinder 4, such as image 3 Shown. Figure 1-3 The control piston 3 exemplarily shown in is used for displacement control of a hydraulic unit (for example, a hydraulic pump or a motor with a reversible hydraulic fluid flow).

[0023] in figure 1 The right side of the control unit 2 shown in, shows the right half of the control piston 3 slidably guided inside the control cylinder 4. The intrinsically safe actuator 6 acts only and indirectly on the control piston 3 via the plunger 17. The displacement of the control piston 3 connects / disconnects some pipes for hydraulic fluid to adjust the displacement of the hydraulic unit. These connections are opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com