Preheat steam multi-pipe bypass temperature regulating system for small-capacity boiler

A technology of reheating steam and temperature adjustment system, which is applied in the direction of steam superheating, steam generation, and superheating temperature control. Ease of operation and reliable thermostat performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

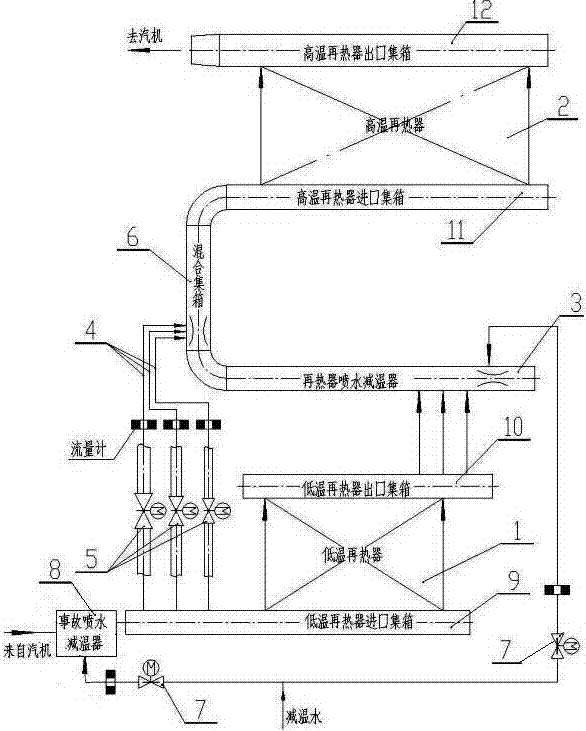

[0013] like figure 1 As shown, it includes low-temperature reheater 1, high-temperature reheater 2, reheater spray desuperheater 3, low-temperature reheater steam bypass pipe 4, electric gate valve 5, mixing header 6, desuperheating water regulating valve 7. Accident spray desuperheater 8. Low temperature reheater inlet header 9. Low temperature reheater outlet header 10. High temperature reheater inlet header 11. High temperature reheater outlet header 12. The emergency spray desuperheater 8 connected to the steam turbine is respectively connected to the low-temperature reheater inlet header 9 and more than three low-temperature reheater steam bypass pipes 4 connected in parallel through pipes, and the low-temperature reheater inlet header 9 is connected upwards Low temperature reheater 1, low temperature reheater 1 connects upward to low temperature reheater outlet header 10, low temperature reheater outlet header 10 is connected to reheater water spray desuperheater 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com