Manufacturing method of petroleum coke for test

A production method and technology of petroleum coke, applied in the preparation of test samples, etc., can solve the problems of inability to reflect the performance of petroleum coke, random sampling of petroleum coke, unfavorable utilization of petroleum coke, etc., so as to facilitate later utilization, increase surface area, and facilitate crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

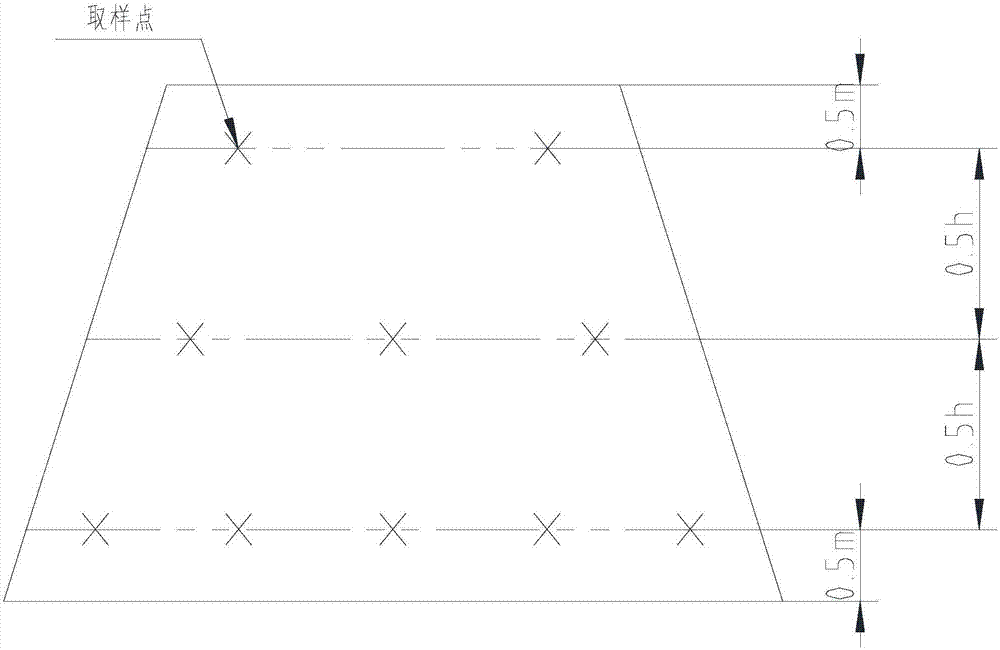

[0025] Such as figure 1 Shown, the preparation method of petroleum coke for assay of the present invention comprises the steps:

[0026] Step A Sampling: Select several circular lines from top to bottom on the focal pile for sampling, and the sampling points on each circular line on the focal pile increase sequentially from top to bottom;

[0027] Step B sample division: After mixing the samples obtained in step A evenly, divide them into two equal parts to form A sample and B sample;

[0028] Step C: Preliminary crushing: smashing sample A so that the particle size of petroleum coke is less than 10mm;

[0029] Step D drying: put the petroleum coke obtained in step C into an oven for drying;

[0030] Step E crushing again: cooling the petroleum coke obtained in step D first, and then crushing it so that the petroleum coke particles can completely pass through a sieve with an aperture of 0.15 mm.

[0031] The closer to the ground on the coke pile, the greater the water conte...

Embodiment 2

[0034] The present invention is based on embodiment 1, and the present invention is further described.

[0035] Such as figure 1 As shown, in the method for making petroleum coke for testing in the present invention, there are three circumferential lines, which are the lower circumferential line 0.5m from the ground on the coke pile, the upper circumferential line 0.5m from the top, and the lower circumferential line and the upper circumferential line. Midcircumferential lines with equidistant circumference lines, such as figure 1 shown.

[0036] Further, three, five, and eight sampling points are arranged at equal intervals on the upper, middle, and lower circumferences, respectively, and the sampling of each sampling point is not less than 0.5kg. When the petroleum coke pile has been stacked for more than 10 days, the sampling point on the circumference line should be 0.2m-0.3m away from the surface of the coke pile.

Embodiment 3

[0038] The present invention is based on embodiment 1, and the present invention is further described.

[0039] Such as figure 1 As shown, in the method for making petroleum coke for testing in the present invention, the drying temperature of the drying box is 100°C-110°C. The drying time of the drying box is not less than 30 minutes. After the petroleum coke is initially pulverized, it is dried and cooled and pulverized again. By first increasing the surface area of the petroleum coke, it is beneficial for drying and evaporating water, which in turn facilitates the smooth progress of step E and facilitates further pulverization of the petroleum coke.

[0040] Further, keep the sample B and the unused samples sealed and kept for re-examination arbitration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com