Iron ore powder assimilation temperature detection method

A detection method and technology for iron ore powder, which are applied in the direction of measuring device, strength characteristics, and the strength of materials using a stable tension/pressure test, can solve the problems of high subjectivity in the detection of assimilation temperature, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

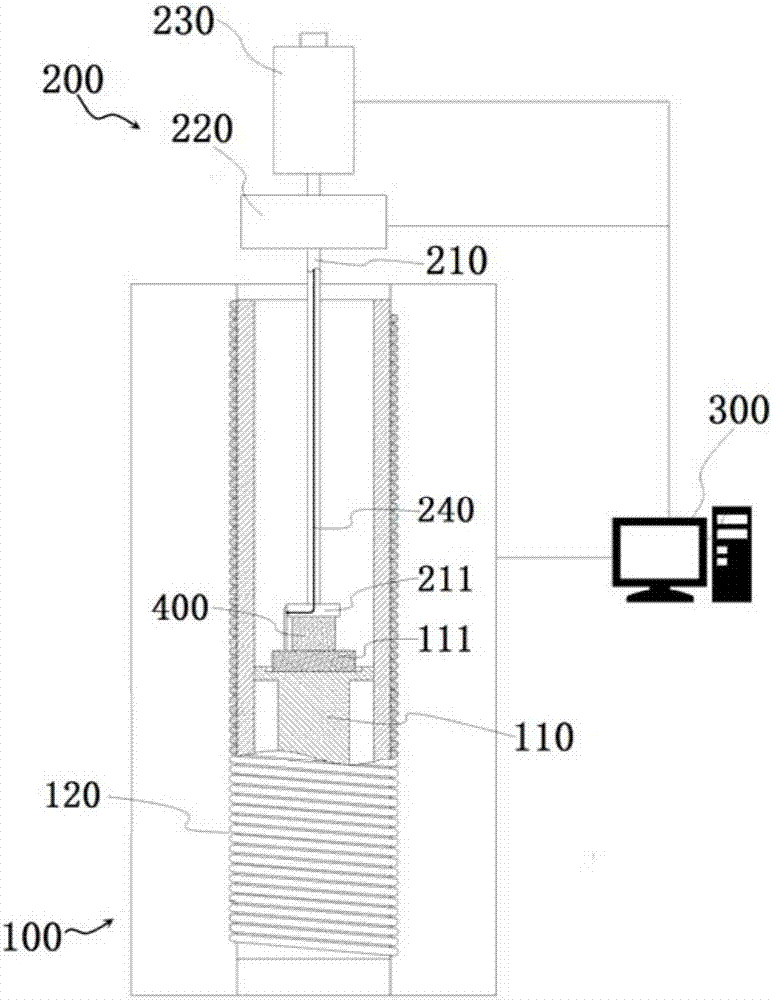

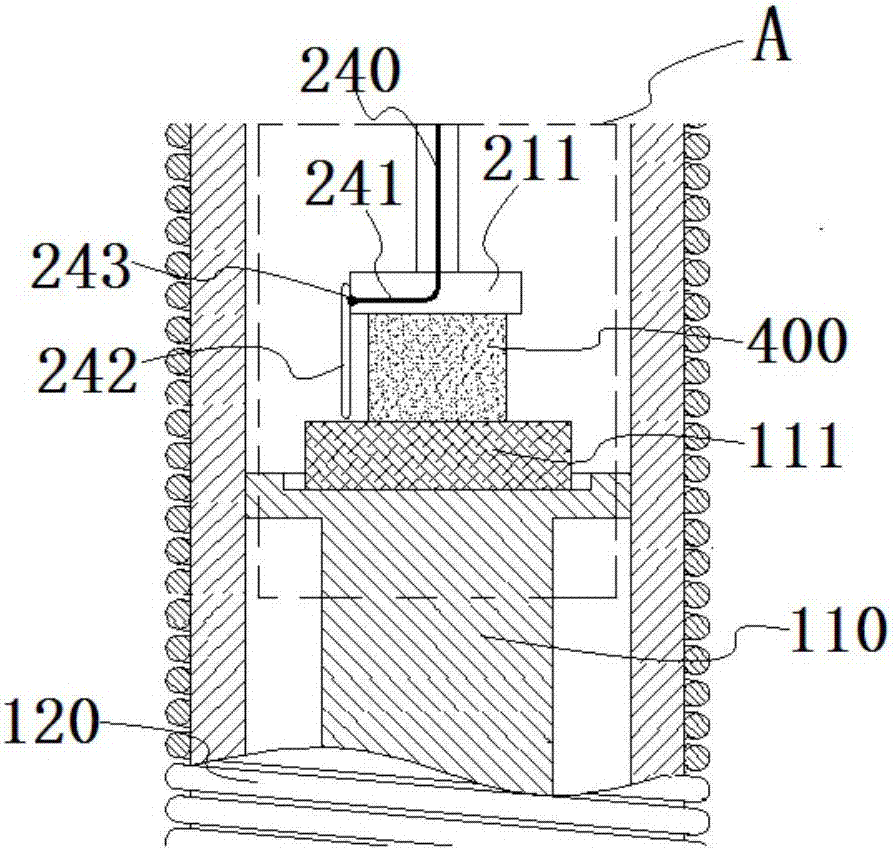

[0041] combine figure 1 , figure 2 with image 3 , a device for detecting assimilation temperature of iron ore powder based on displacement mutation in this embodiment includes a heating unit 100 and a detection unit 200; wherein the heating unit 100 includes a sample stage 110 and a heating furnace 120, and the sample stage 110 is arranged in the heating furnace In 120, the heating unit 100 is used for heating the iron ore powder sample 400 on the sample stage 110; figure 1 shown), of course, the heating furnace 120 can also be heated in other ways, for example: infrared heating and the like.

[0042] The detection unit 200 includes a measuring rod 210, a displacement sensor 220 and a force applying mechanism 230; the top of the measuring rod 210 is connected with the force applying mechanism 230, and the force applying mechanism 230 is used to drive the measuring rod 210 to apply pressure to the iron ore powder sample 400; The bottom of the rod 210 is provided with a sam...

Embodiment 2

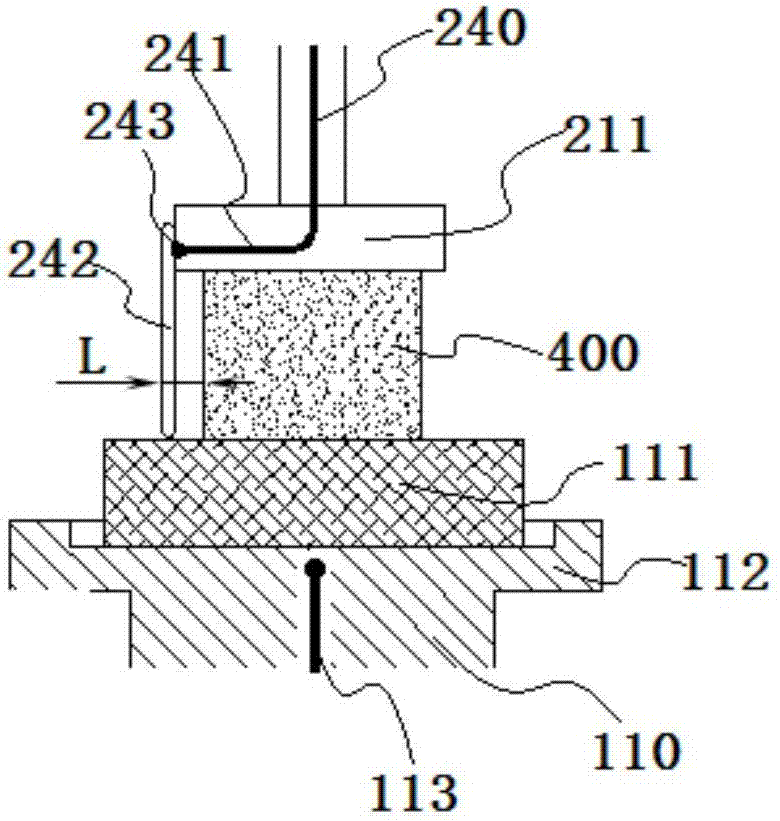

[0053] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that the temperature-measuring thermocouple 240 is provided with a thermocouple horizontal section 241, and the temperature-measuring end 243 is arranged at the end of the thermocouple horizontal section 241 (such as figure 2 As shown), the thermocouple horizontal section 241 is arranged in the sample pressing part 211, and the temperature measuring end 243 is located at the edge of the sample pressing part 211, that is, the end of the thermocouple horizontal section 241 extends to the iron ore powder sample The edge position of 400, the temperature measuring end 243 of the temperature measuring thermocouple 240 is close to the edge position of the iron ore powder sample 400, thereby improving the accuracy of the temperature detection around the iron ore powder sample 400, and then improving the iron ore powder assimilation temperature The accuracy of detection provides relia...

Embodiment 3

[0055] The basic content of this embodiment is the same as that of Embodiment 1, the difference is that: the temperature measuring end 243 is connected with the auxiliary temperature measuring rod 242, the auxiliary temperature measuring rod 242 is arranged at the edge position of the sample pressing part 211, and the auxiliary temperature measuring rod 242 is set along the vertical direction; the distance between the auxiliary temperature measuring rod 242 and the edge of the iron ore powder sample 400 is L, then 1mm<L<2mm, the present embodiment L=1.5mm, the material of the auxiliary temperature measuring rod 242 is carbonization Silicon; the auxiliary temperature measuring rod 242 is arranged parallel to the edge of the iron ore powder sample 400 , and the bottom of the auxiliary temperature measuring rod 242 is in contact with the surface of the CaO pressure sheet 111 . The auxiliary temperature measuring rod 242 of this embodiment is close to the edge of the iron ore powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com