Automatic feed delivery control method

A technology of automatic feeding and control method, applied in the direction of program control, computer control, general control system, etc., can solve the problems of increasing costs and risks for farmers, failing to meet the refinement requirements, low breeding efficiency, etc., to improve feed High utilization rate, high judgment accuracy, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

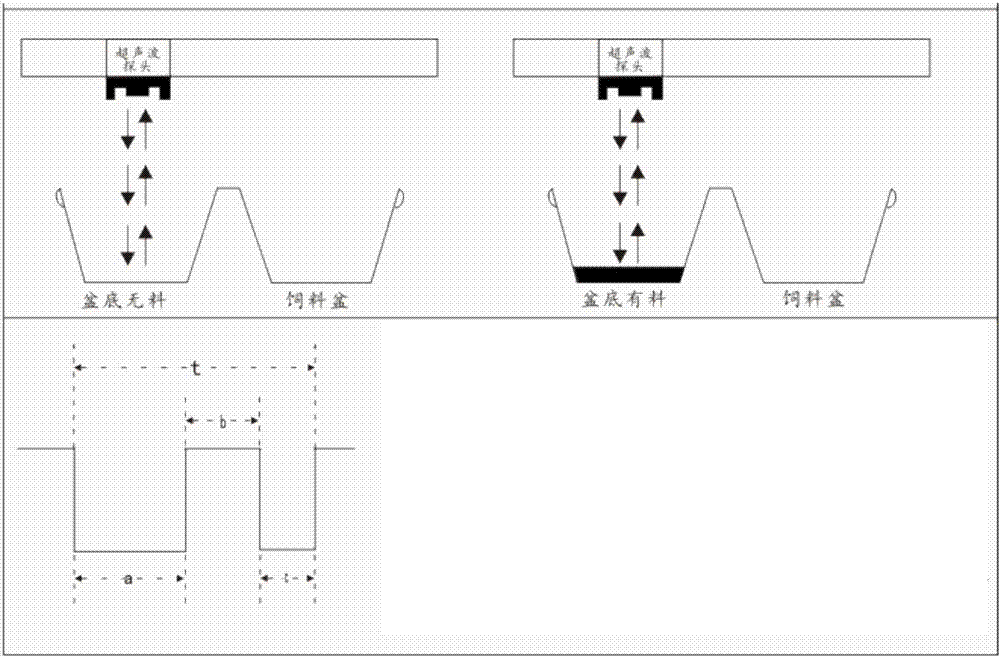

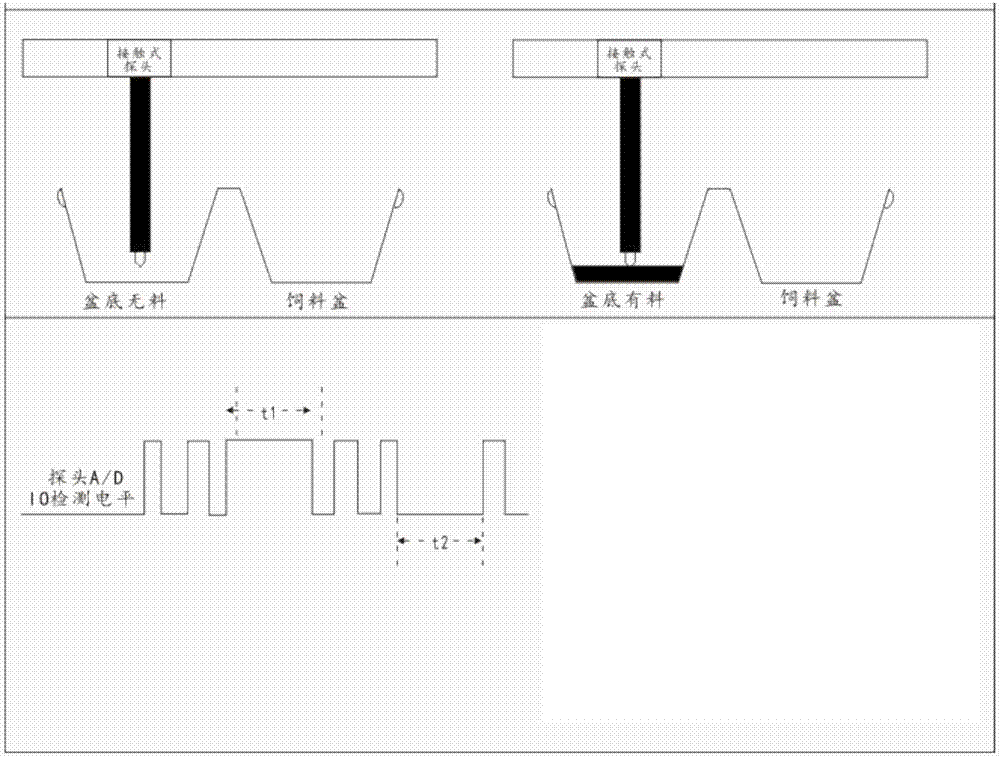

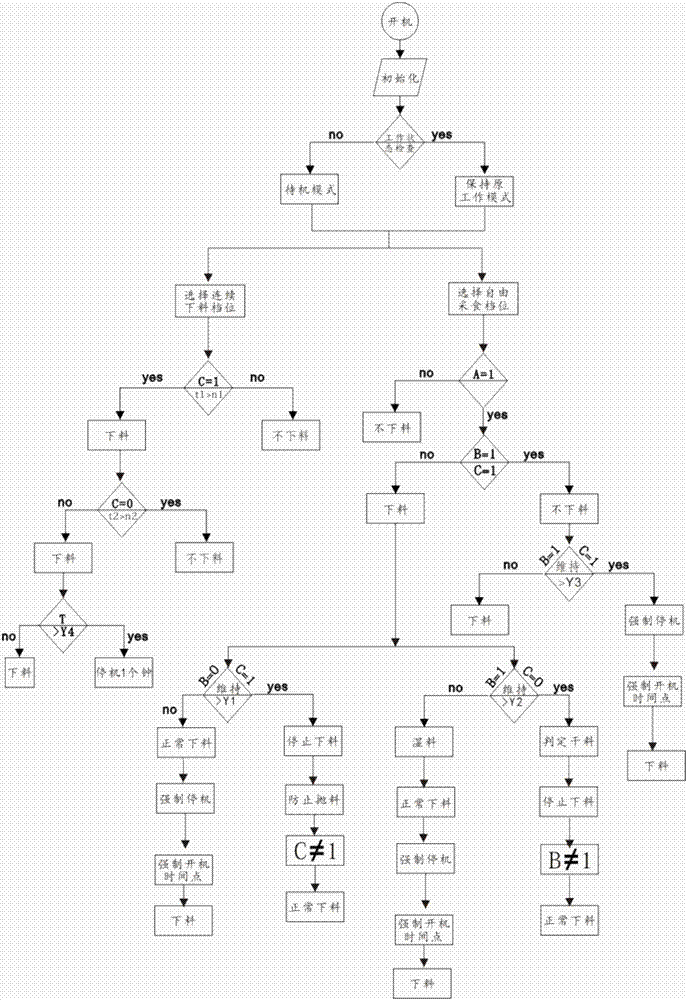

[0022] refer to figure 1 , figure 2 As shown, the embodiment of the present invention discloses a method for automatically feeding feed control, the method includes the following steps:

[0023] The main control MCU controls the ultrasonic probe sensor to send an ultrasonic detection signal to the bottom of the feed basin, and compares the returned detection signal with the set parameter signal value to determine the presence and height of the feed;

[0024] The main control MCU controls the contact probe sensor to sample whether there is feed in the feed basin, and sends the sampling level to the main control MCU, and the main control MCU obtains the high level signal and low level signal according to the sampling. Keep the time and compare it with the set reference signal value to determine the presence or absence of feed;

[0025] The clock chip circuit generates a stable clock signal to communicate with the main control MCU, and the main control MCU controls the ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com