Intelligent automatic control system for IoT intelligent dedusting device system

A technology of dust removal equipment and automatic control system, applied in general control system, control/regulation system, program control, etc., can solve problems such as the inability to solve the exact time of opening the dust removal equipment, shorten the service life of the dust removal equipment, and damage the health of the body, and achieve Achieve high-speed acquisition and real-time data transmission, good versatility and scalability, and improve the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

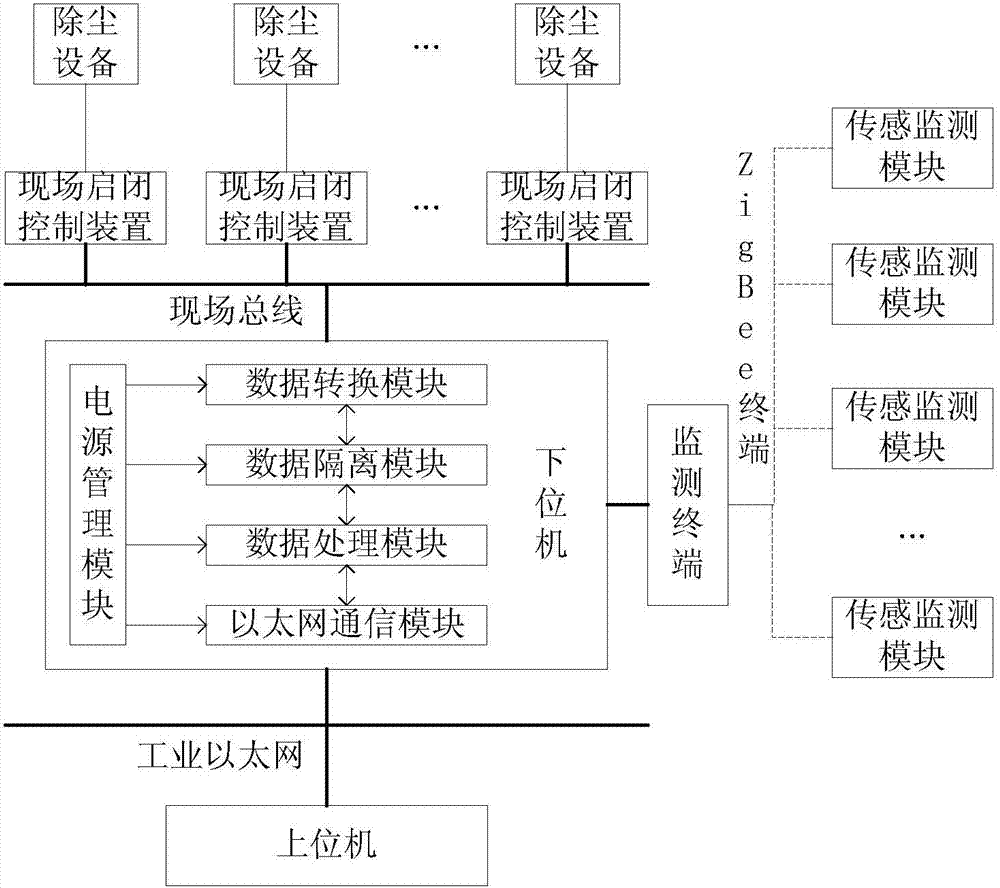

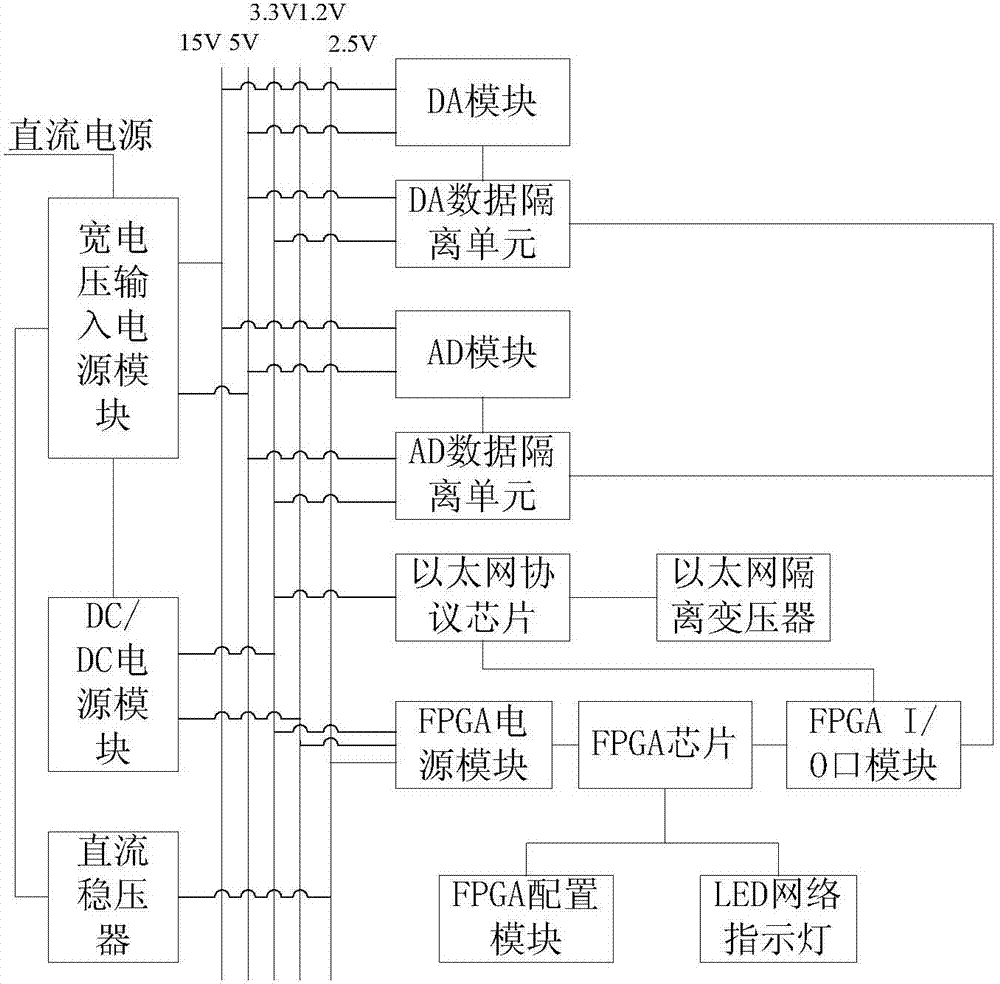

[0027] Such as figure 1 with 2 As shown, an intelligent automatic control system for the intelligent dust removal equipment system of the Internet of Things, especially for dust removal equipment systems for flammable and explosive dust and safety explosion-proof, spark detection, automatic fire extinguishing, automatic alarm, automatic start-up in the production process Intelligent management and control system for automatic closing, automatic injection of inert gas, automatic explosion-proof and explosion-venting, etc., including the on-site opening and closing control device for controlling the switch of dust removal equipment, on-site sensing data monitoring components, lower computer, industrial Ethernet and upper computer. The on-site opening and closing control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com