Brush DC motor speed regulation method based on least square classified velocity measurement

A brushed DC motor, least squares technology, applied in the field of excitation or armature current control, etc., can solve the problem that the sensorless speed regulation of brushed DC motors has not yet appeared, so as to avoid network learning and adjustment, save hardware costs, The effect of improving speed measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

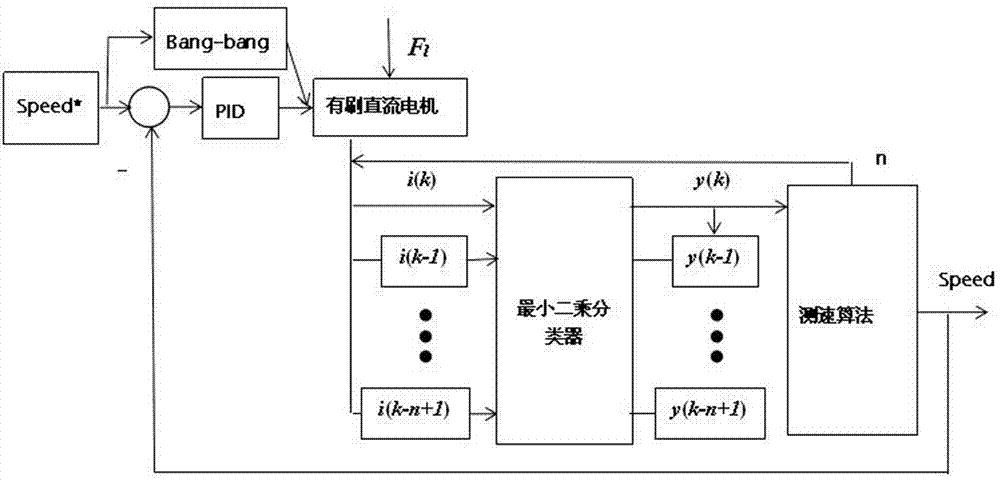

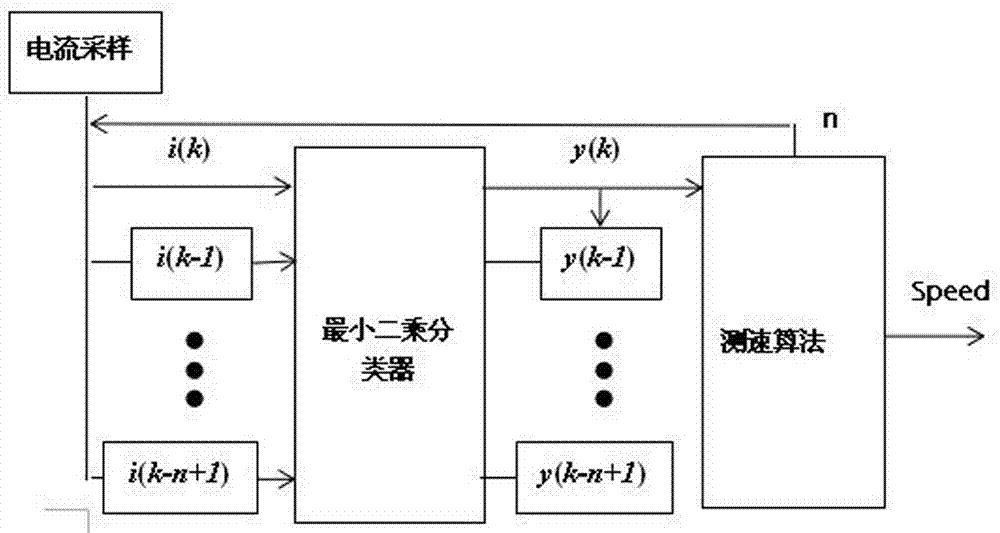

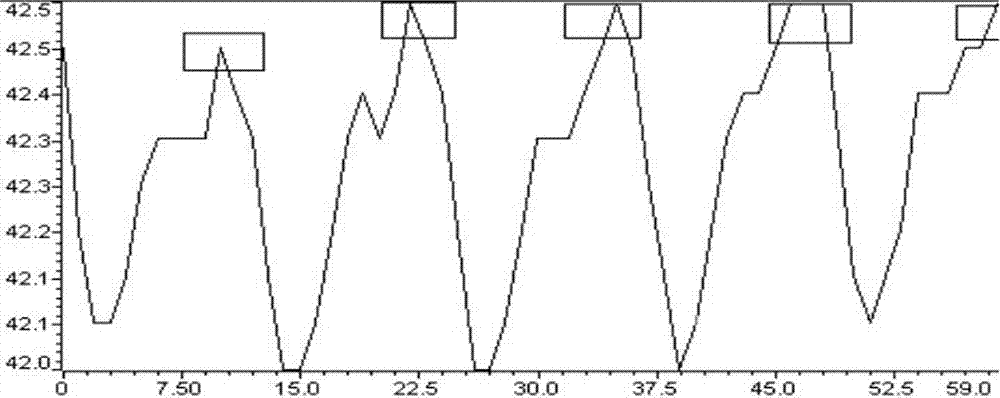

[0031] The invention provides a brushed DC motor speed regulation method based on the least squares classification speed measurement. The least squares classification method is used to measure the speed and only needs to extract the current ripple. The speed can completely replace the speed measured by the encoder and feed back to the PID control. The input terminal of the controller realizes sensorless speed regulation. The number of commutation rectifications is fixed when the motor rotates one circle, and the current ripple is generated by the commutation. The current ripple period is equal to the commutation period, and each ripple period has only one peak, so the sampling time is determined, and the number of detected peaks can be used to calculate the speed; A linear classifier based on the least squares method is used to identify p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com