Steam type tea leaf green removing machine

A technology of a greening machine and a steam engine, which is applied in the direction of tea processing before extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

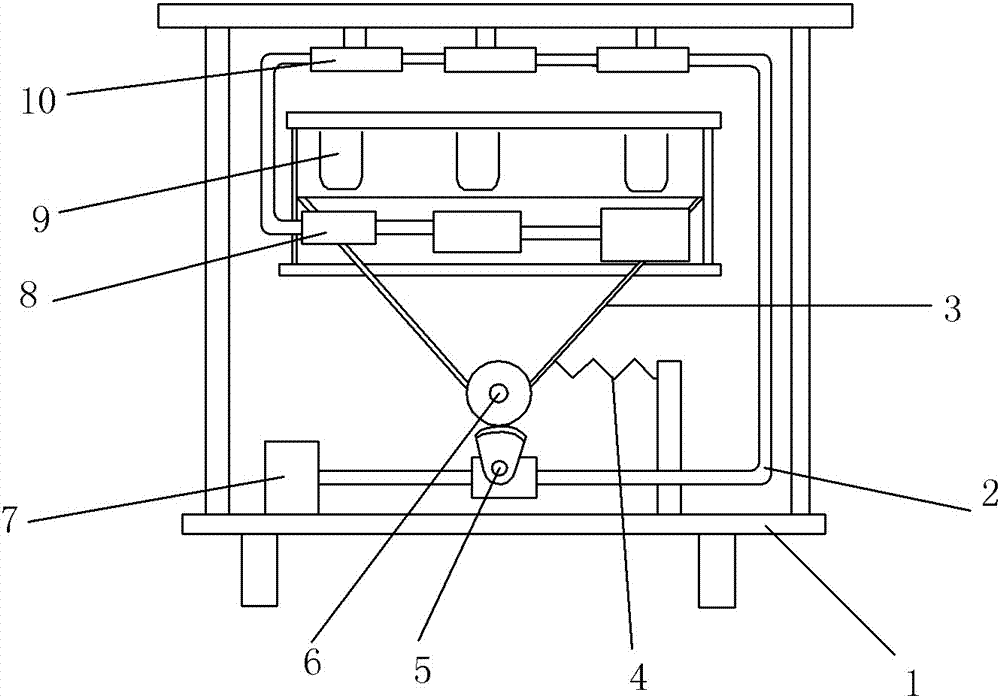

[0023] Such as figure 1 As shown, the steam-type tea greening machine of the present invention includes a frame 1 and a steam engine 7 arranged above the frame 1, the right side of the steam engine 7 is connected with a fan-shaped tooth 5 through a steam pipe 2, and the fan-shaped tooth 5 is coaxially connected with a turbine (Fig. Not shown in), the gear 6 is meshed above the fan-shaped teeth 5, the gear 6 is connected with the three frying pans 9 above through the support rod 3, and the right end of the support rod 3 is connected with the spring 4. Three first heaters 8 are arranged below the frying pan 9 respectively, and the thickness of the upper part of the first heater 8 gradually increases from left to right. A second heater 10 is also arranged above the frying pan 9 .

[0024] During operation, different tealeaves are put into frying pan 9 respectively according to the temperature of tealeaves finishing, and the higher temperature requirement is placed in the first h...

Embodiment 2

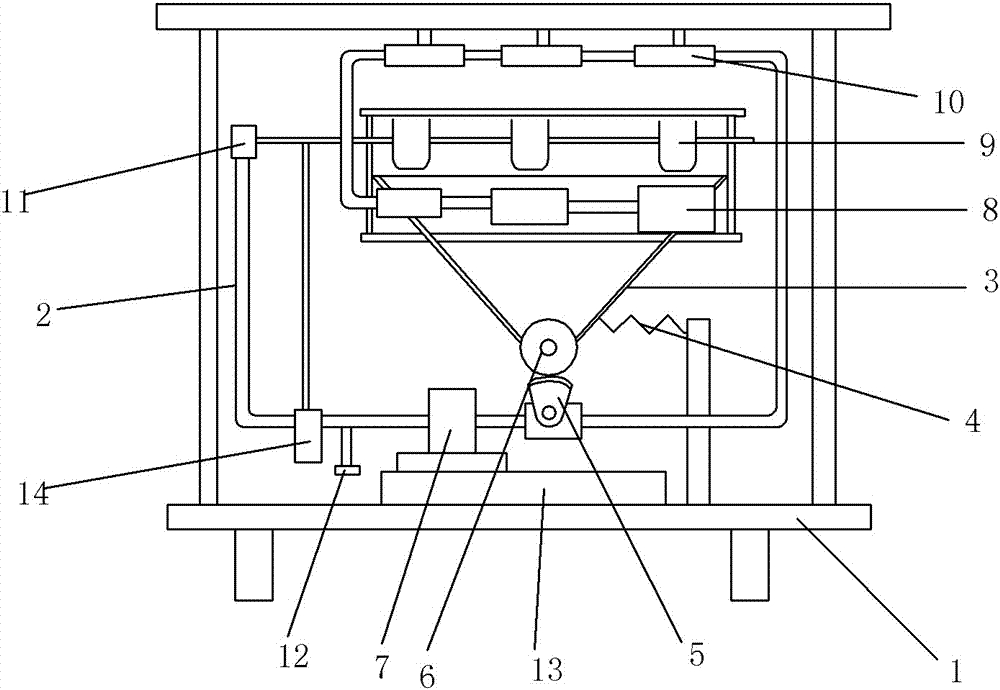

[0026] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that a rack 13 is provided below the fan-shaped teeth 5, and the left end of the steam engine 7 is connected with a rotating device 11 through a steam pipe 2, and the rotating device 11 is connected to the frying pan through a connecting shaft. 9 connections. A trigger switch 12 is arranged on the steam pipe, and a wedge 14 is also connected between the rotating device 11 and the wok 9 .

[0027] The position of the rack 13 is determined according to the tea roasting time and the rotating speed of the fan-shaped tooth 5. When the tea roasting is completed, the rack 13 just contacts the switch 12, the switch 12 is opened, and the steam flows into the rotating device 11 and rotates. The device 11 drives the frying pan 9 to rotate, and the tea leaves in the frying pan 9 are poured out. At the same time, the rotating device 11 drives the wedge 14 to swing. When the tea le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com