Laboratory fiber asphalt macadam seal layer synchronous spreading device

A kind of asphalt gravel, laboratory technology, used in roads, road repair, roads, etc., can solve the problems of inconvenient operation, disturbing the normal spraying of fibers, and low test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

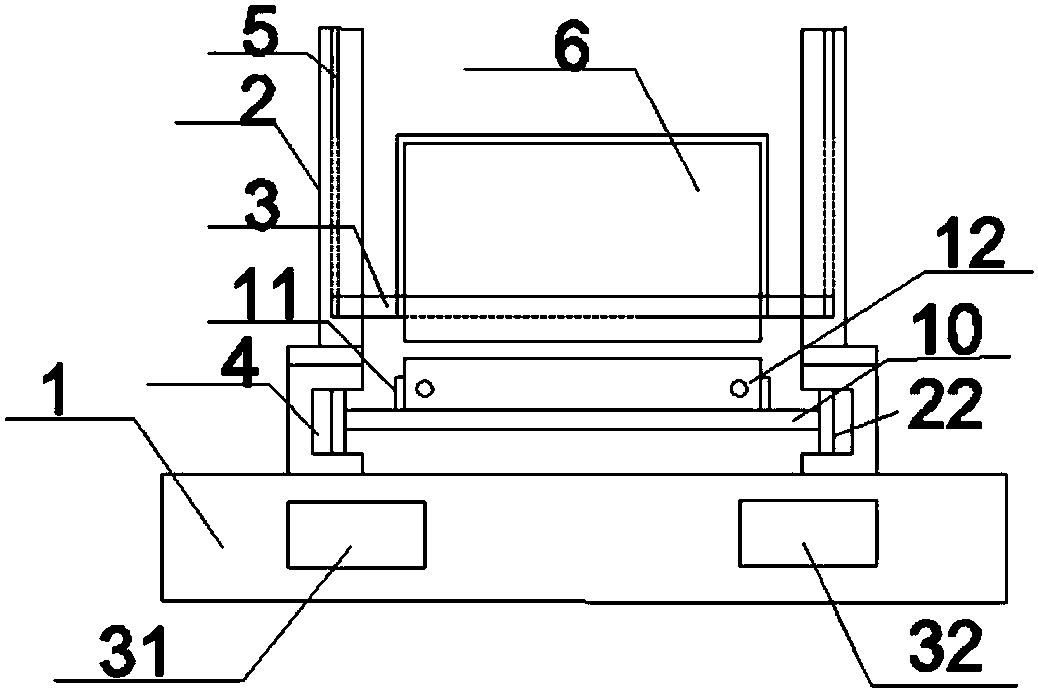

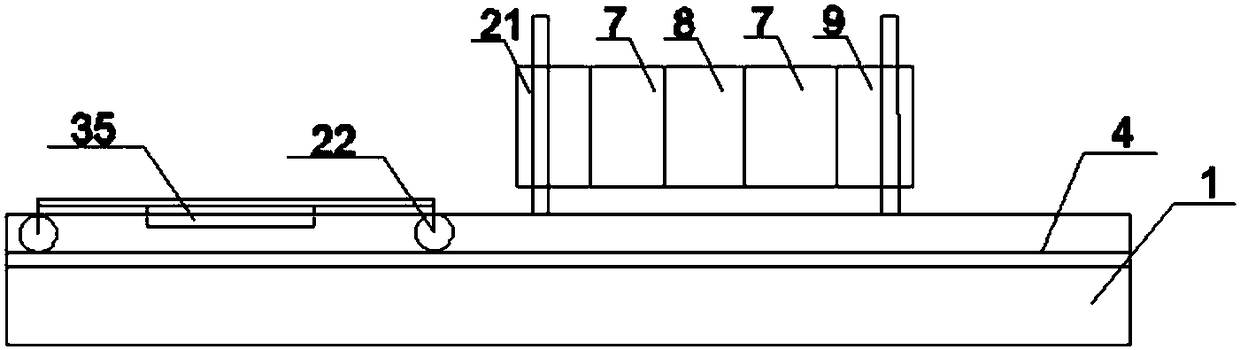

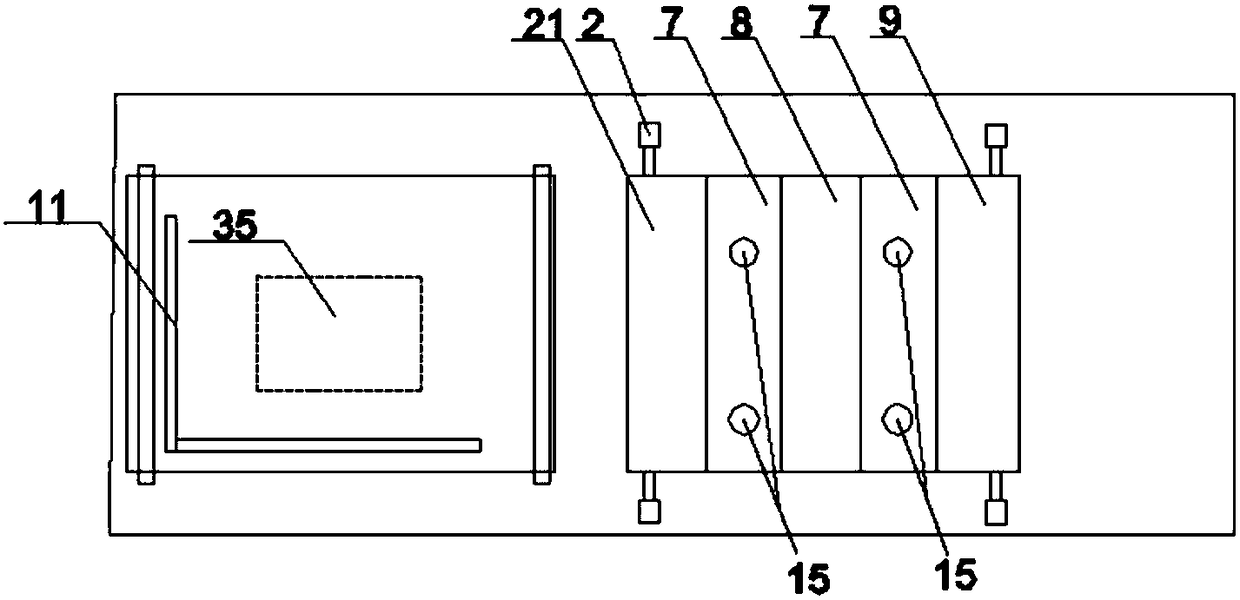

[0034] Such as Figure 1 to Figure 4 As shown, a laboratory fiber asphalt macadam seal layer synchronous sprinkling device, including support frame device and fiber asphalt macadam comprehensive distribution box 6;

[0035] Wherein the support frame device includes a base 1 and two sliding rails 4 arranged in parallel on the base 1, the inner sides of the two sliding rails 4 are provided with sliding grooves, and the sliding grooves are provided with test pieces that can slide in the sliding grooves The bearing plate 10 is used to place the rut plate specimen to be tested on the test piece bearing plate 10; the two slide rails 4 are vertically provided with a vertical slide rail support 2, and the vertical slide rail support 2 is provided with a lifting chain 5, The fiber asphalt gravel comprehensive distribution box 6 is connected with the lifting chain 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com