Reverse cleaning device for filter screen in sewage treatment pipeline

A reverse cleaning and sewage treatment technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of clogging of the filter screen, difficult removal of impurities, and difficult maintenance, etc., to facilitate removal, improve cleaning effect, and avoid blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

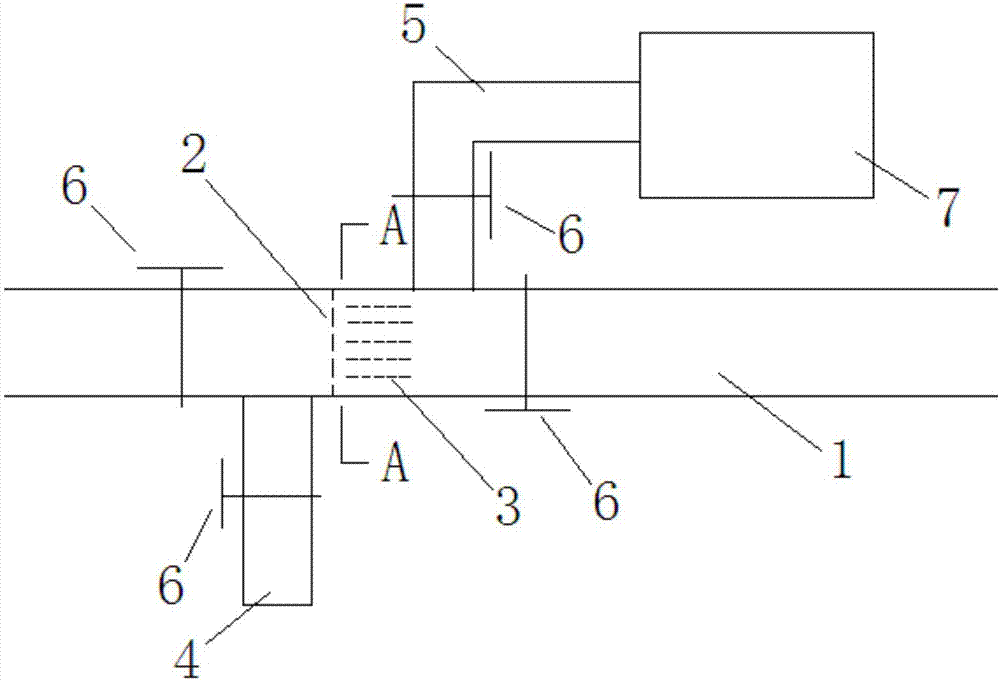

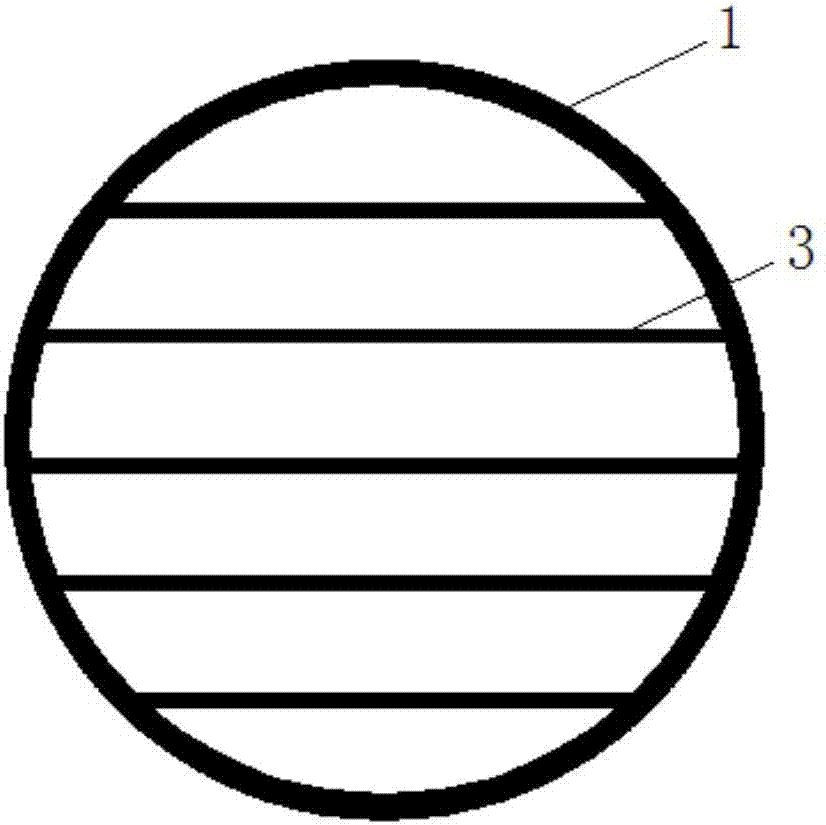

[0014] refer to figure 1 and figure 2 , a reverse cleaning device for a filter screen in a sewage treatment pipeline provided in this embodiment, comprising a sewage pipe 1 and a filter screen 2, the filter screen 2 is arranged in the sewage pipe 1, and the sewage pipe 1 is located on the downstream side of the filter screen 2 Five deflectors 3 are arranged horizontally, and the five deflectors 3 are evenly distributed vertically and equally spaced in the sewage pipe 1, that is, any two adjacent deflectors 3 leave a vertically equidistant deflector gap , the sewage pipe 1 on the upper and lower reaches of the filter screen 2 is also connected with a slag discharge pipe 4 and a flushing pipe 5 respectively, and the flushing pipe 5 is arranged downstream of the deflector 3, and both the slag discharge pipe 4 and the flushing pipe 5 are set There is a valve 6, valve 6 is also set on the sewage pipe 1 upstream of the slag discharge pipe 4 and the sewage pipe 1 downstream of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com