A two-time glue spraying process for the back plate of a disc brake pad

A technology of disc brake and back plate, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. It can solve the problems of low friction coefficient at high temperature, low shear strength, glue overflow, etc. Achieve the effects of stable friction coefficient at high temperature, guaranteed braking safety, and improved bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

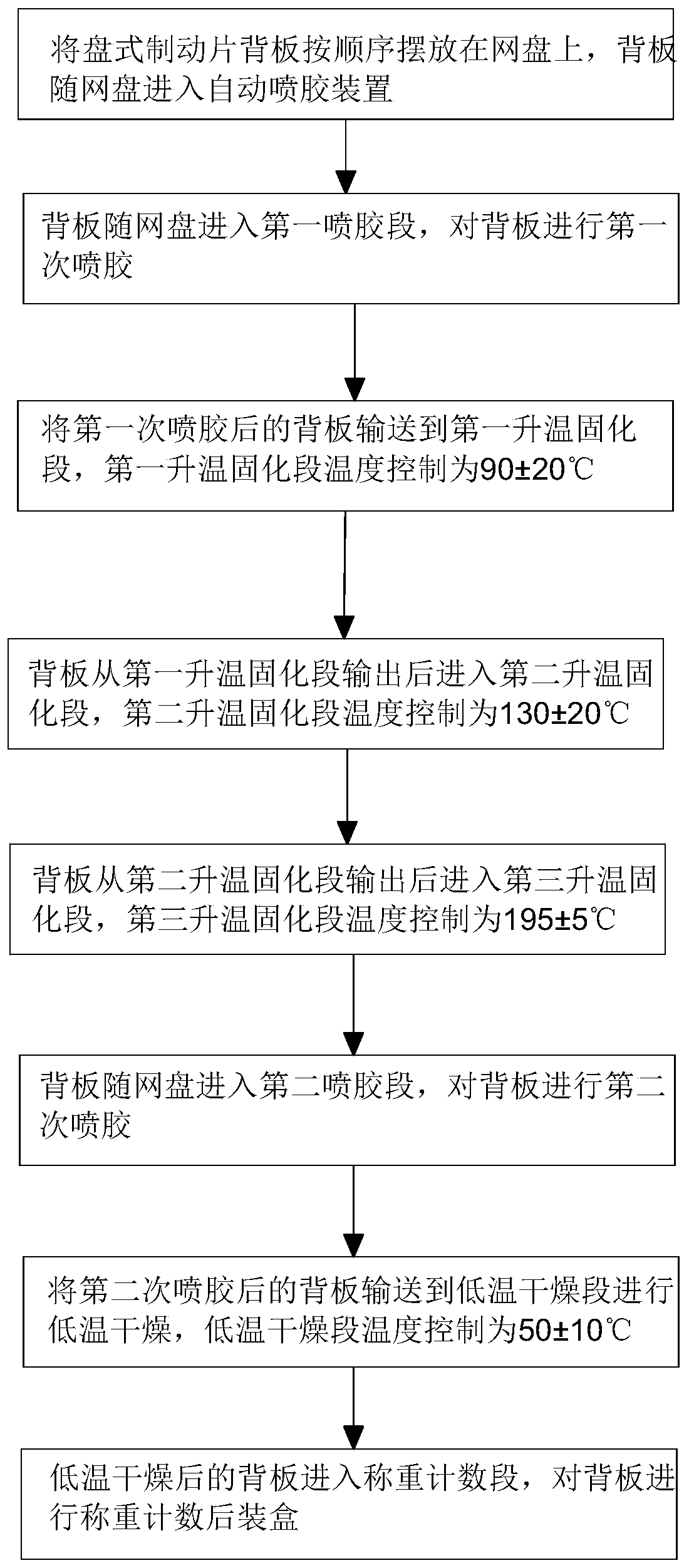

[0031] Such as figure 1 Shown, provide a kind of double glue spraying process of disc brake pad back plate, described glue spraying process comprises the steps:

[0032] Step 1. Place the disc brake pad back plates on the net disk in order, and the back plate enters the automatic glue spraying device with the net disc; the disc brake pads are discharged in sequence, without tilting, extrusion, or flipping and other phenomena, the network disk is made of stainless steel, and before use, ensure that there is no deformation of the network disk to prevent chucking during the transportation process;

[0033] Step 2. The backplane enters the first glue spraying section along with the network disk, and spray glue on the backplane for the first time; the glue used for the first spray glue is colorless and transparent glue, and the colorless and transparent glue is composed of epoxy Adhesive, the specific gravity of colorless and transparent glue is 0.8790-0.890, the atomization press...

Embodiment 2

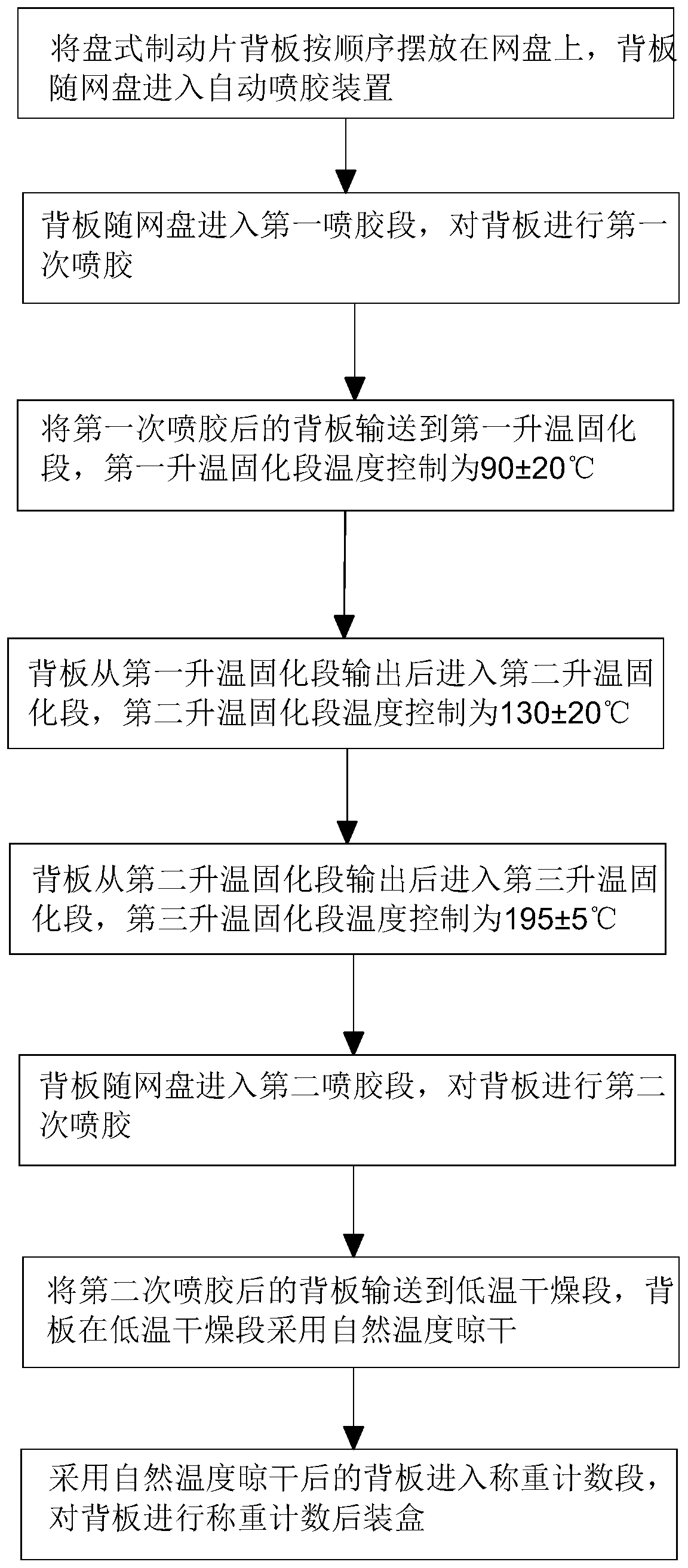

[0043] Such as figure 2 Shown, provide a kind of double glue spraying process of disc brake pad back plate, described glue spraying process comprises the steps:

[0044] Step 1. Place the disc brake pad back plates on the net disk in order, and the back plate enters the automatic glue spraying device with the net disc; the disc brake pads are discharged in sequence, without tilting, extrusion, or flipping and other phenomena, the network disk is made of stainless steel, and before use, ensure that there is no deformation of the network disk to prevent chucking during the transportation process;

[0045] Step 2. The backplane enters the first glue spraying section along with the network disk, and spray glue on the backplane for the first time; the glue used for the first spray glue is colorless and transparent glue, and the colorless and transparent glue is composed of epoxy Adhesive, the specific gravity of colorless and transparent glue is 0.8790-0.890, the atomization pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com