Numerical control machine tool convenient to dedust

A technology of CNC machine tools and machine tools, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of debris accumulation, difficult to clean, etc., to achieve long strokes, avoid short circuits, and good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

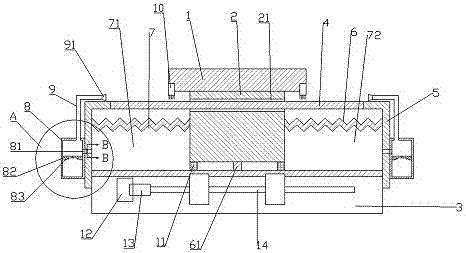

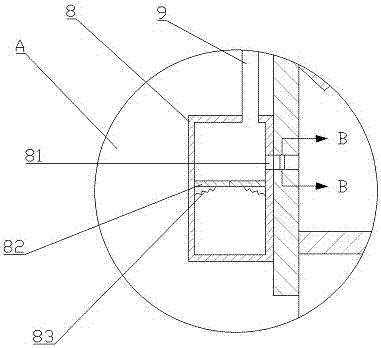

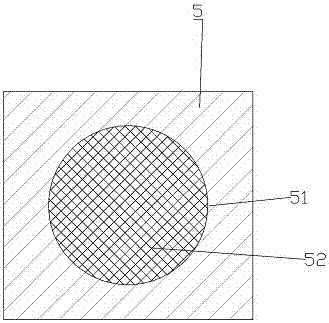

[0023] The reference signs in the drawings of the description include: workbench 1, base 2, through groove 21, machine bed bridge 3, dust-proof pad 4, L-shaped dust-proof plate 5, vent 51, filter screen 52, organ dust-proof Cover 6, partition 61, dust-proof cavity 7, first compression chamber 71, second compression chamber 72, collection box 8, opening 81, opening and closing plate 82, light spring 83, dust removal pipe 9, dust guide pipe 91, Dust removal brush 10, guide rail pair 11, servo motor 12, coupling 13, ball screw pair 14.

[0024] Such as figure 1 As shown, the CNC machine tool that is convenient for dust removal includes a machine bed bridge 3, a workbench 1, and a base 2 connected to the workbench 1. The base 2 is connected to the machine tool bed bridge 3 through a ball screw pair 14 and a guide rail pair 11. The balls One end of screw mandrel pair 14 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com