A method for reducing microwave curing stress of composite materials

A technology of composite materials and microwave curing, which is applied in the field of microwave curing of composite materials and reducing the stress of microwave curing of composite materials. Stress, meet the needs of use, improve the effect of curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

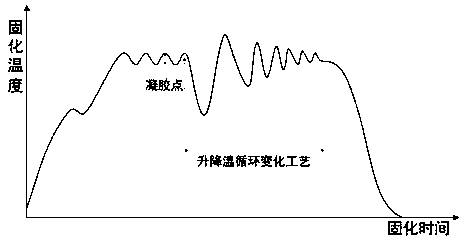

[0022] Such as figure 2 shown.

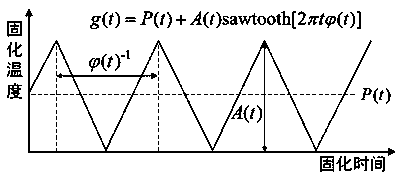

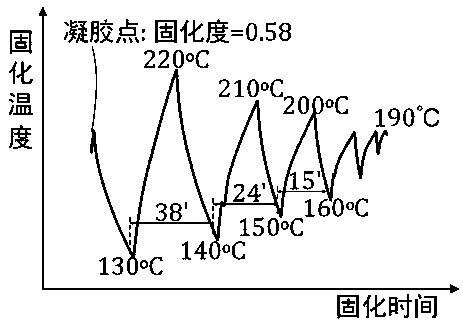

[0023] A method for reducing the microwave curing stress of composite materials. In the microwave curing process of composite materials, after the resin reaches the gel point, the curing temperature will increase and decrease with time (that is, a cycle of high and low), and the cycle changes until The temperature process at which the composite is fully cured. The range of temperature rise and fall is above 10 degrees Celsius, and the heating rate and cooling rate can vary with the curing time, and they are different, such as figure 2 shown. During specific implementation, it is also possible to directly cool down after heating up, then heat up, and repeat the cycle. It can also be kept warm at the temperature turning point (the temperature range is no more than 5 degrees Celsius) for a period of time and then cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com