Circular conveying apparatus

A conveying device and circulating technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of blocked conveying, conveying action obstacles, conveying pollution, etc., so as to reduce poor conveying or conveying pollution, realize high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

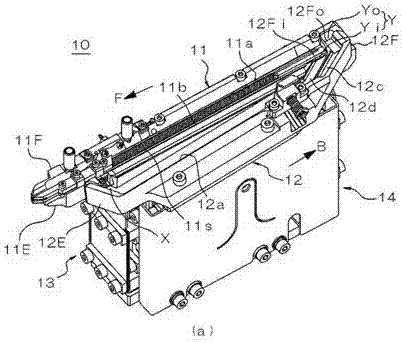

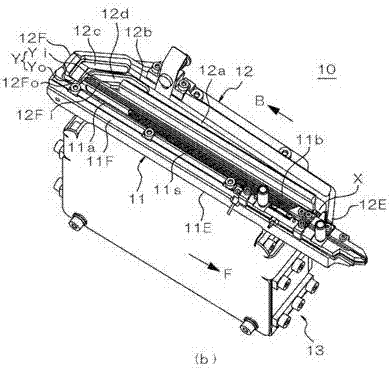

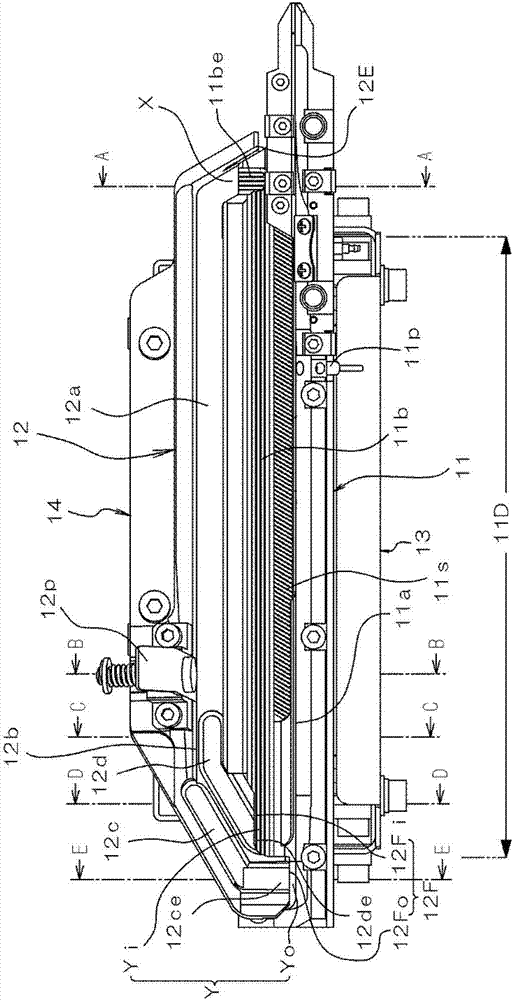

[0068] Next, an embodiment of the circulating conveying device according to the present invention will be described in detail with reference to the drawings. Figure 1 to image 3 It is an external view showing the whole device of this embodiment, Figure 4 to Figure 8 yes figure 2 Enlarged cross-sectional view of each part shown.

[0069] The circulating conveying device 10 of the present embodiment includes a supply-side conveying body 11 mounted on an upper portion of a supply-side vibrating mechanism 13 , and a collection-side conveying body 12 mounted on an upper portion of a collecting-side vibrating mechanism 14 . The supply-side conveyance body 11 and the recovery-side conveyance body 12 are attached in a posture parallel to each other. The supply-side conveyor 11 is composed of a base block 11E mounted on the upper portion of the supply-side vibration excitation mechanism 13 and an attachment block 11F attached to the upper portion of the base block 11E.

[0070] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com