A kind of preparation method of quasi-solid-state electrochromic device

An electrochromic device and electrochromic technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of few reports on the preparation process of quasi-solid-state electrochromic devices, so as to avoid the influence of device performance and uniform color change Good properties, improved coloring efficiency and fading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

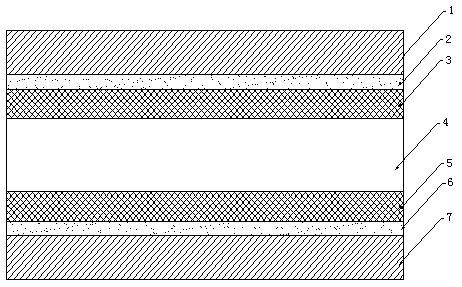

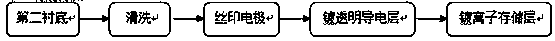

[0034] The preparation method of the quasi-solid-state electrochromic device of the present invention, such as figure 1 As shown, the device is sequentially composed of a first substrate 1, a first transparent conductive layer 2, an electrochromic layer 3, an ion transport layer 4, an ion storage layer 5, a second transparent conductive layer 6 and a second substrate 7; The preparation method comprises the following steps:

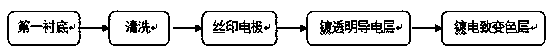

[0035] (1) Prepare the first functional substrate, such as figure 2 as shown,

[0036] Step 1: Use a clean and highly transparent material as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process, as an electrode, and then uniformly spread the conductive silver paste on the surface of the conductive silver paste Deposit a layer of transparent conductive film with a film thickness of 20-400nm to form the first transparent conductive layer 2; ...

Embodiment 1

[0056] The preparation method of the PMMA / PVB gel quasi-solid-state electrochromic device containing lithium ions in this embodiment comprises the following steps:

[0057] (1) Preparation of the first functional substrate:

[0058] Step 1: Use clean plexiglass as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process as an electrode. The screen printing process uses a 200-mesh screen printing screen cloth, the distance between the screen printing mesh and the first substrate is 2-4mm, and the screen printing pressure is 1.5-3bar; then a layer of transparent conductive film with a film thickness of 20-400nm is evenly deposited on the surface of the conductive silver paste by vacuum coating process, and the deposition The temperature is 350-380°C, the deposition power is 12-14kw.h, the transmission speed is 0.8-1.2m / min, and the reaction pressure is 0.5-0.6pa to form...

Embodiment 2

[0071] The preparation method of the PMMA / PVB gel quasi-solid-state electrochromic device containing lithium aluminum ions in this embodiment comprises the following steps:

[0072] (1) Preparation of the first functional substrate:

[0073] Step 1: Use clean plexiglass as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process as an electrode. The screen printing process uses a 200-mesh screen printing screen cloth, the distance between the screen printing mesh and the first substrate is 2-4mm, and the screen printing pressure is 1.5-3bar; then a layer of transparent conductive film with a film thickness of 20-400nm is evenly deposited on the surface of the conductive silver paste by vacuum coating process, and the deposition The temperature is 350-380°C, the deposition power is 12-14kw.h, the transmission speed is 0.8-1.2m / min, and the reaction pressure is 0.5-0.6p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com