Shoelace threading talcum powder scattering device for shoe processing

A technology of wearing shoelaces and talcum powder, which is applied in the direction of grain processing, etc., can solve the problems of slow breaking speed, time-consuming and laborious, waste of talcum powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

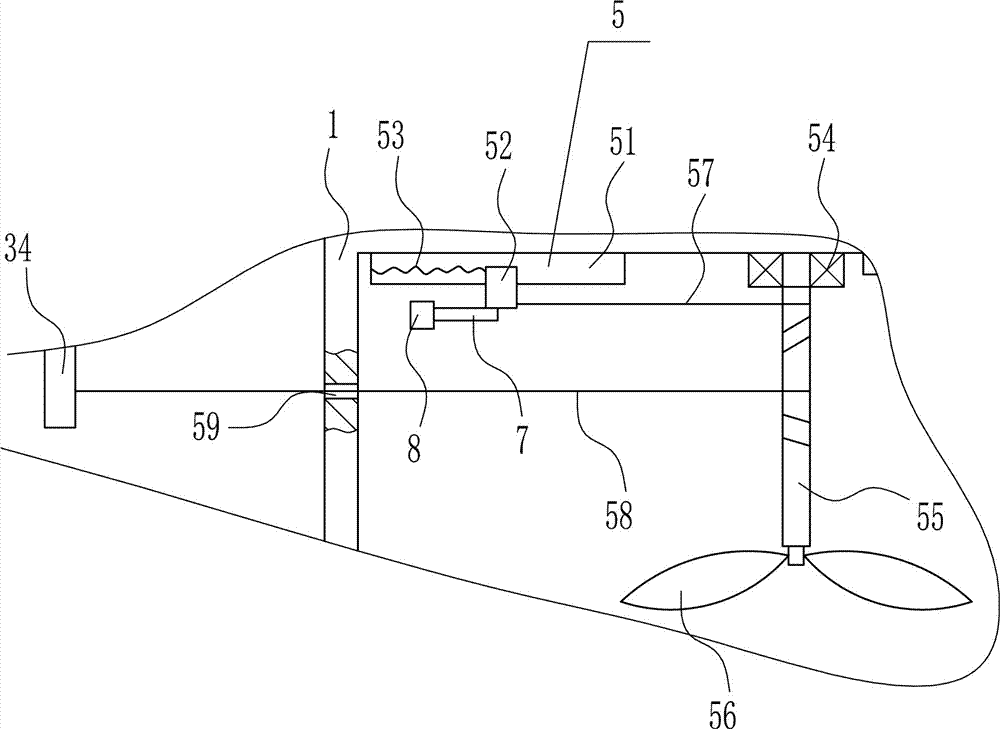

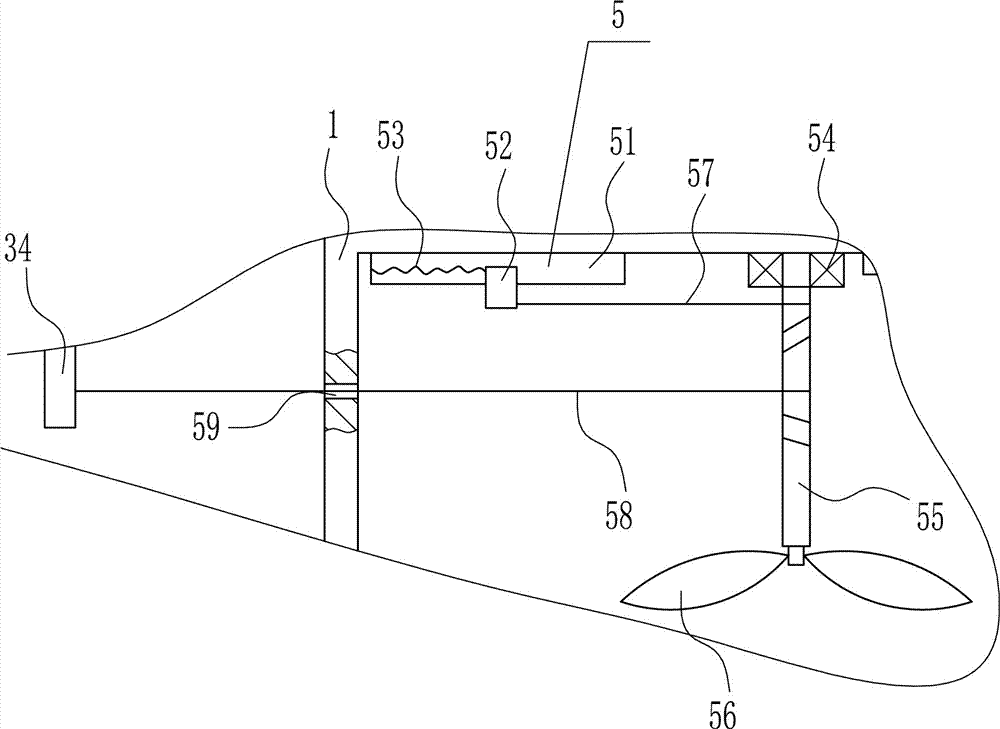

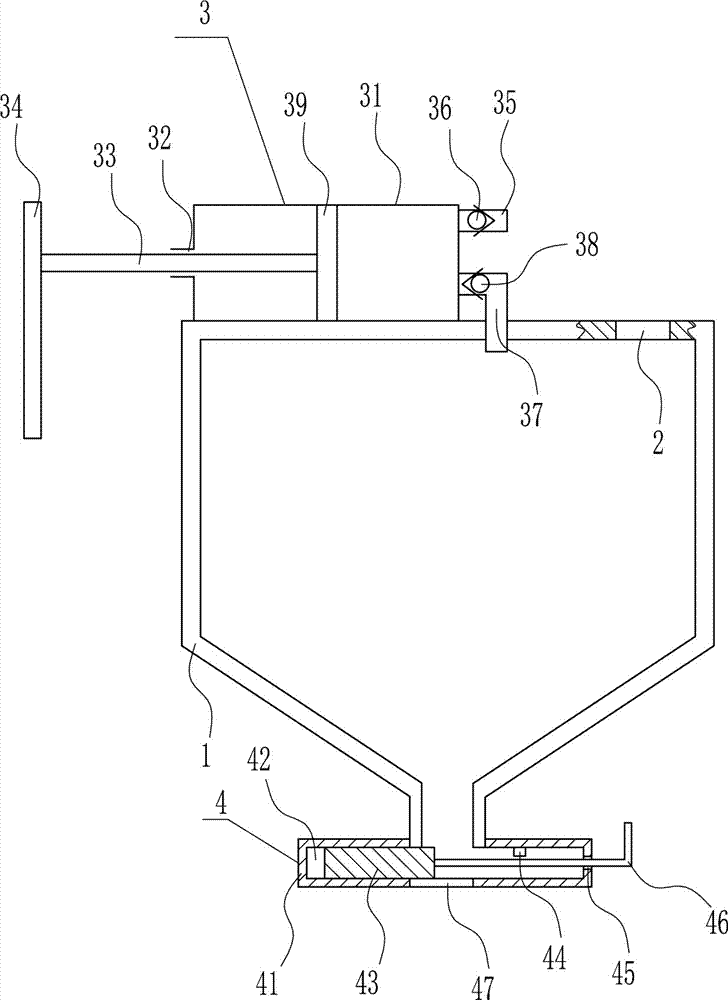

[0036] A kind of talcum powder breaking equipment for shoes processing and wearing shoelaces, such as Figure 1-6 As shown, it includes a metal container 1, an air blowing device 3 and a material retaining device 4. The top right side of the metal container 1 has a discharge port 2, and the top of the metal container 1 is provided with an air blowing device 3. The blowing device 3 The components are located in the metal container 1, the air blowing device 3 is located at the upper left of the discharge opening 2, and the bottom of the metal container 1 is provided with a stopper 4.

Embodiment 2

[0038] A kind of talcum powder breaking equipment for shoes processing and wearing shoelaces, such as Figure 1-6 As shown, it includes a metal container 1, an air blowing device 3 and a material retaining device 4. The top right side of the metal container 1 has a discharge port 2, and the top of the metal container 1 is provided with an air blowing device 3. The blowing device 3 The components are located in the metal container 1, the air blowing device 3 is located at the upper left of the discharge opening 2, and the bottom of the metal container 1 is provided with a stopper 4.

[0039] The blowing device 3 includes a compression cylinder 31, a push rod 33, a pull block 34, an air inlet pipe 35, a first one-way valve 36, an air outlet pipe 37, a second one-way valve 38 and a piston 39, and the left side of the metal container 1 passes through A compression cylinder 31 is installed in the way of bolt connection, and the upper part of the right side of the compression cylind...

Embodiment 3

[0041] A kind of talcum powder breaking equipment for shoes processing and wearing shoelaces, such as Figure 1-6 As shown, it includes a metal container 1, an air blowing device 3 and a material retaining device 4. The top right side of the metal container 1 has a discharge port 2, and the top of the metal container 1 is provided with an air blowing device 3. The blowing device 3 The components are located in the metal container 1, the air blowing device 3 is located at the upper left of the discharge opening 2, and the bottom of the metal container 1 is provided with a stopper 4.

[0042] The blowing device 3 includes a compression cylinder 31, a push rod 33, a pull block 34, an air inlet pipe 35, a first one-way valve 36, an air outlet pipe 37, a second one-way valve 38 and a piston 39, and the left side of the metal container 1 passes through A compression cylinder 31 is installed in the way of bolt connection, and the upper part of the right side of the compression cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com