Industrial digital production on-line quality intelligent detection and sorting device

A technology of intelligent detection and sorting device, applied in sorting and other directions, can solve the problems of low repeatability of measurement data and high cost, and achieve the effect of ensuring orderly arrangement, improving feeding efficiency, and avoiding mechanical jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

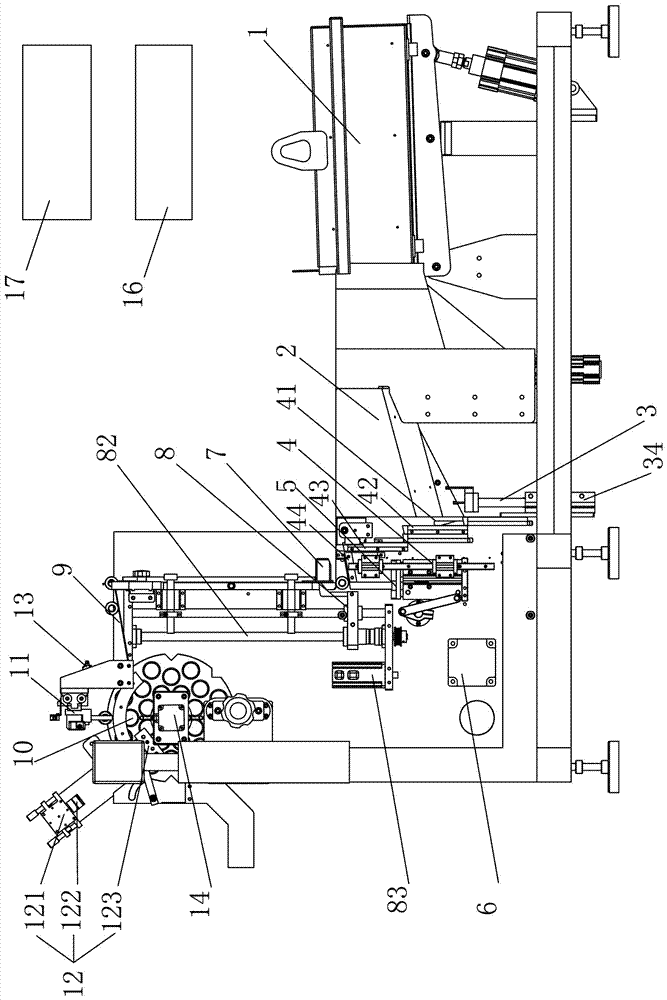

[0029] The content of the present invention will be further explained below in conjunction with the accompanying drawings and taking pin shaft products as an example to help understand the content of the present invention.

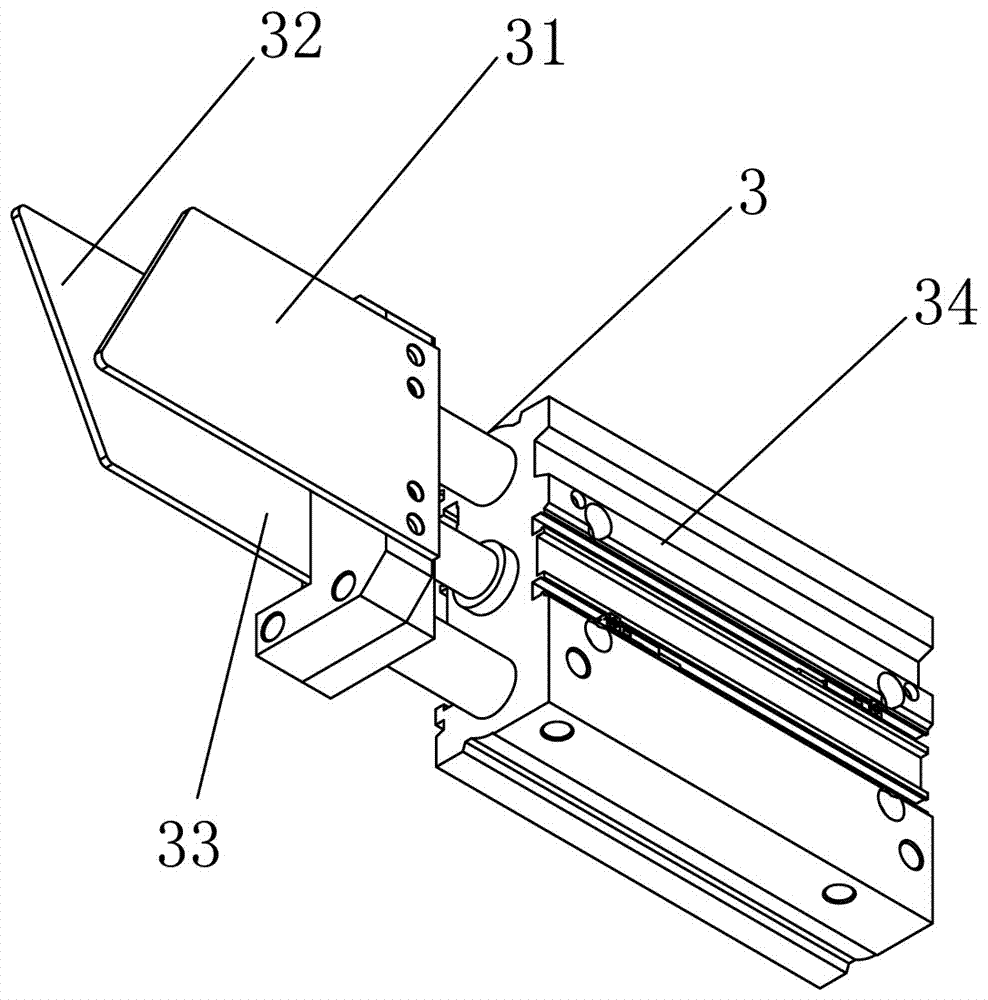

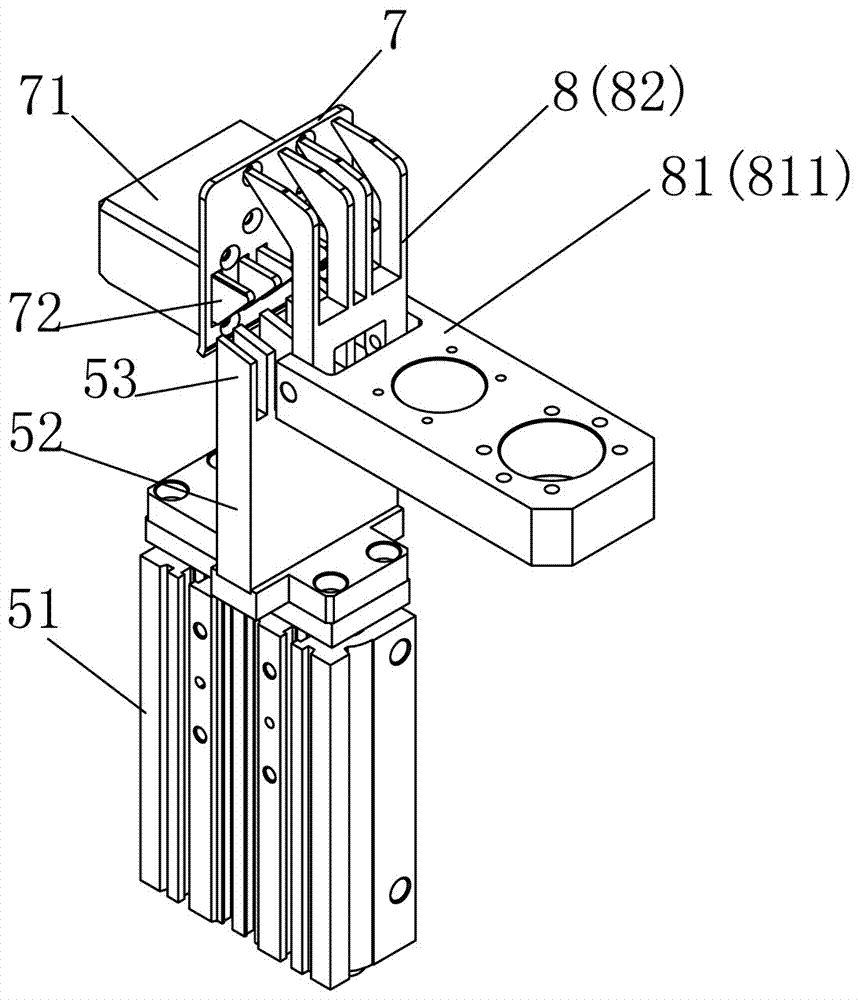

[0030] See figure 1 - Image 6 , An embodiment of an industrial digital production on-line quality intelligent detection and sorting device of the present invention includes a feeding bin 1. The discharge port of the feeding bin 1 is provided with a primary waiting area 2, and a preliminary guide is set below the primary waiting area 2 Device 3. The pre-correcting device 3 includes a first correcting plate 31 and a second correcting plate 32 that are arranged oppositely. The top ends of the first and second correcting plates 31, 32 are arranged as opposite slopes, so that the first and second correcting plates 31 The area between, 32 forms a guide zone 33 with an included angle a of 124 degrees, and the lower parts of the first and second guide plates 31 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com