Upsetting forming method of ultra-large height-diameter ratio metal blank

A high-diameter ratio, metal billet technology, applied in the field of plastic processing, can solve problems such as the inability to select a larger diameter billet, the bottleneck of forging forming, and the difficulty in controlling the internal structure quality, so as to simplify the upsetting process and reduce upsetting The effect of increasing power and expanding the processing range of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

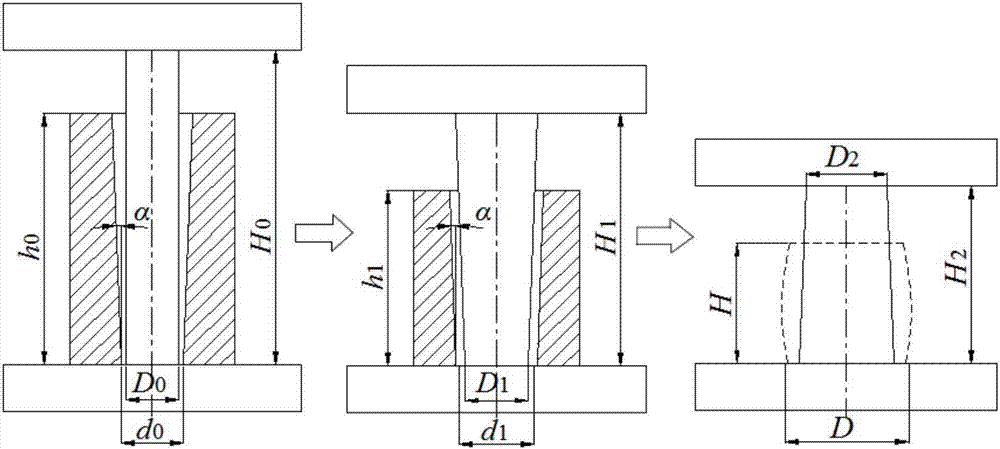

[0019] Such as figure 1 As shown, taking the upsetting of a steel billet with a height-to-diameter ratio of 7 as an example, the initial upsetting size of the billet is diameter D 0 =600mm, height H 0 = 4200mm, the target size of the upset forming part is diameter D = 1000mm, height H = 1512mm, the upset forming is realized according to the following steps:

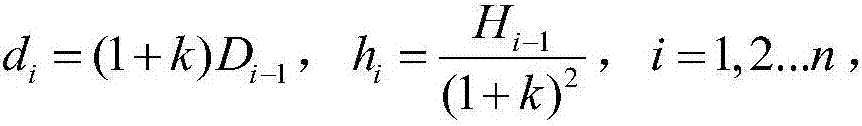

[0020] 1) Determine the upsetting pass in the mold, and calculate it according to the following formula:

[0021] Taking the diameter increase rate k of the upsetting blank in the mold as 20%, and the height-to-diameter ratio λ of the free upsetting blank as 2.34, the calculation determines that the number of upsetting passes in the mold is two times, and the entire upsetting process is two times in the mold , free upsetting once;

[0022] 2) The upsetting ratio design is calculated according to the following formula:

[0023] Determine the upsetting ratio of the two molds as 30.56%, and the free upsetting ratio a...

Embodiment 2

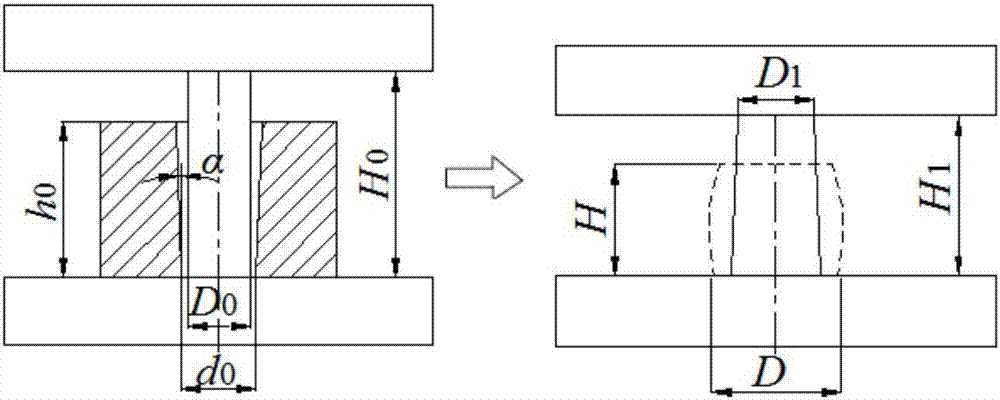

[0029] Such as figure 2 As shown, taking the upsetting of an aluminum alloy billet with a height-to-diameter ratio of 3.3 as an example, the initial upsetting size of the billet is diameter D 0 =500mm, height H 0 = 1650mm, the target size of the upset forming part is diameter D = 660mm, height H = 947mm, the upset forming is realized according to the following steps:

[0030] 1) Determine the upsetting pass in the mold, and calculate it according to the following formula:

[0031] Taking the diameter increase rate k of the upsetting blank in the mold as 15%, and the height-to-diameter ratio λ of the free upsetting blank as 2.17, the calculation determines that the upsetting pass in the mold is one time, and the entire upsetting process is one upsetting in the mold, free upsetting once;

[0032] 2) The upsetting ratio design is calculated according to the following formula:

[0033] The upsetting ratio in the mold is 24.39%, and the free upsetting ratio is 24.10%;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com