Preparation method of bending strain sensing fabric with wireless signal transmission function

A bending strain, wireless signal technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of inability to sense the bending deformation of the antenna, the structure is not stable enough, the deformation of the textile structure, etc. Stable and uniform effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] combine figure 1 , the preparation of the three-dimensional woven structure single radiating element bending sensing antenna fabric, the specific method is as follows:

[0036] (1) Bare copper wire is selected as the conductive yarn with a diameter of 0.5 mm; elastic polyethylene yarn with good dielectric properties is selected with a fineness of 400tex.

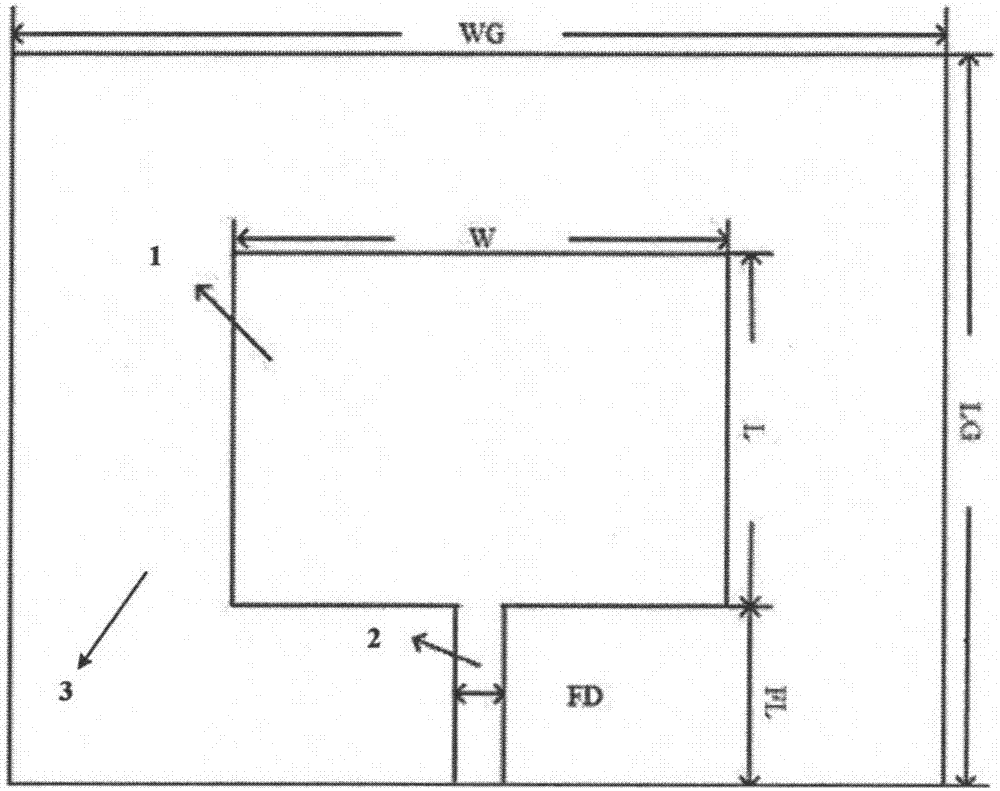

[0037] (2) The operating frequency of the antenna is designed to be 1.5GHz, the thickness of the prepared three-dimensional fabric is 2.5mm, and its dielectric constant r=1.5, according to the antenna design theory (see Chapter 6 of "Antenna Theory and Technology", edited by Zhong Shunshi) , the size parameters of the single radiating element microstrip antenna are calculated. figure 1 Among them, W and L are the width and length of the radiating element respectively, WG and LG are the width and length of the finished microstrip antenna, FL is the length of the feeder line, and FD is the width of the feeder line.

...

Embodiment 2

[0043] combine figure 2 , the preparation of the three-dimensional woven structure double radiator bending strain sensing fabric, the specific method is as follows:

[0044] (1) Choose bare copper wire as the conductive yarn, with a diameter of 0.5 mm; choose aramid yarn with good dielectric properties, with a fineness of 400tex.

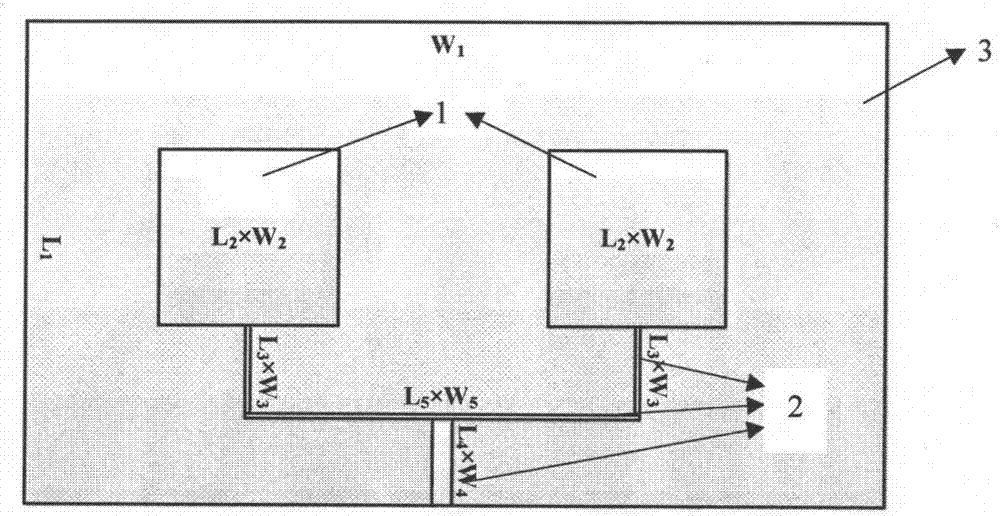

[0045] (2) The working frequency of the designed antenna is 2 GHz, the thickness of the prepared three-dimensional fabric is 2.5 mm, and its dielectric constant r = 4.5, and the size parameters of the single radiating element microstrip antenna are calculated according to the antenna design theory, as shown in figure 2As shown, where W1 and L1 are the width and length of the sensing fabric, W2 and L2 are the width and length of the radiating element patch respectively, L3, L4, L5 are the lengths of the feeder lines, and W3, W4, W5 are the widths of the feeder lines.

[0046] (3) Weaving the single radiating element microstrip antenna prefab. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com