Device for removing hub window burrs

A technology for burrs and hubs, which is applied in the field of devices for removing burrs from hub windows, can solve problems such as large dust and occupational disease risks, and achieve the effects of liberating manpower, realizing automation, and reducing occupational disease risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

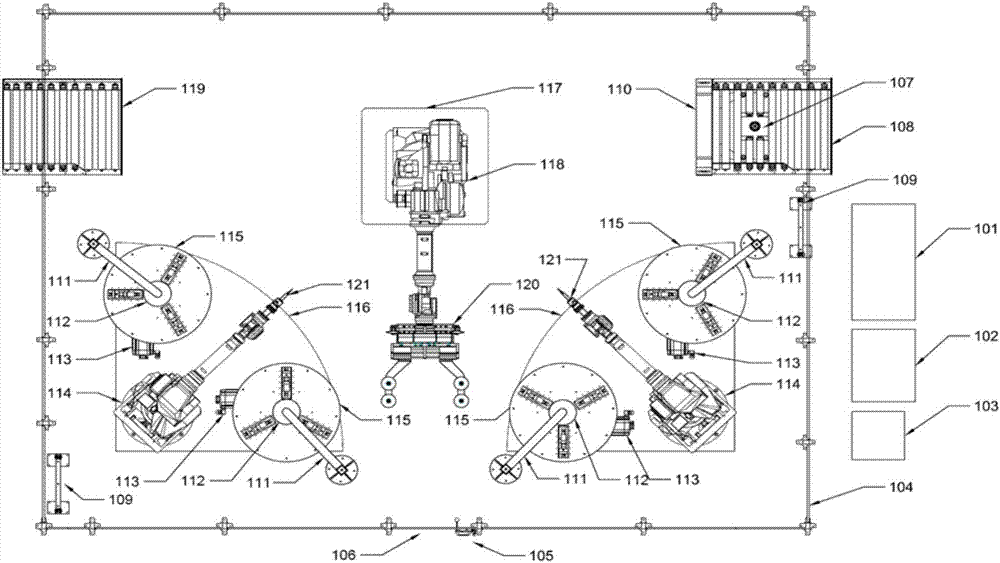

[0022] A device for removing burrs from hub windows, which consists of a feeding roller table (108), a pneumatic plate (109), a vision device bracket (111), a vision device (112), a milling burr robot (114), a turntable (115 ), a fan-shaped bottom plate (116), a robot bottom plate (117), a handling robot (118), a discharge roller table (119), and a pneumatic grinding tool (121), and is characterized in that: the feed roller table (108) and the discharge roller table (108) The material roller table (119) is respectively fixed to the two ends of the device platform; one or more fan-shaped bottom plates (116) are installed on the device platform, and the side of the fan-shaped bottom plate (116) is equipped with a visual device bracket (111) 1. The visual device (112) is fixed on the visual device support (111); the fan-shaped bottom plate (116) is fixed with a turntable (115) and a milling burr robot (114); the end of the milling burr robot (114) is equipped with a pneumatic grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com