Wheel suspension for a motor vehicle

A wheel suspension, motor vehicle technology, applied in the direction of suspension, elastic suspension, cantilever installed on the pivot, etc., can solve the problems such as the strength defect of the sub-frame, and achieve the effect of reducing the preload load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

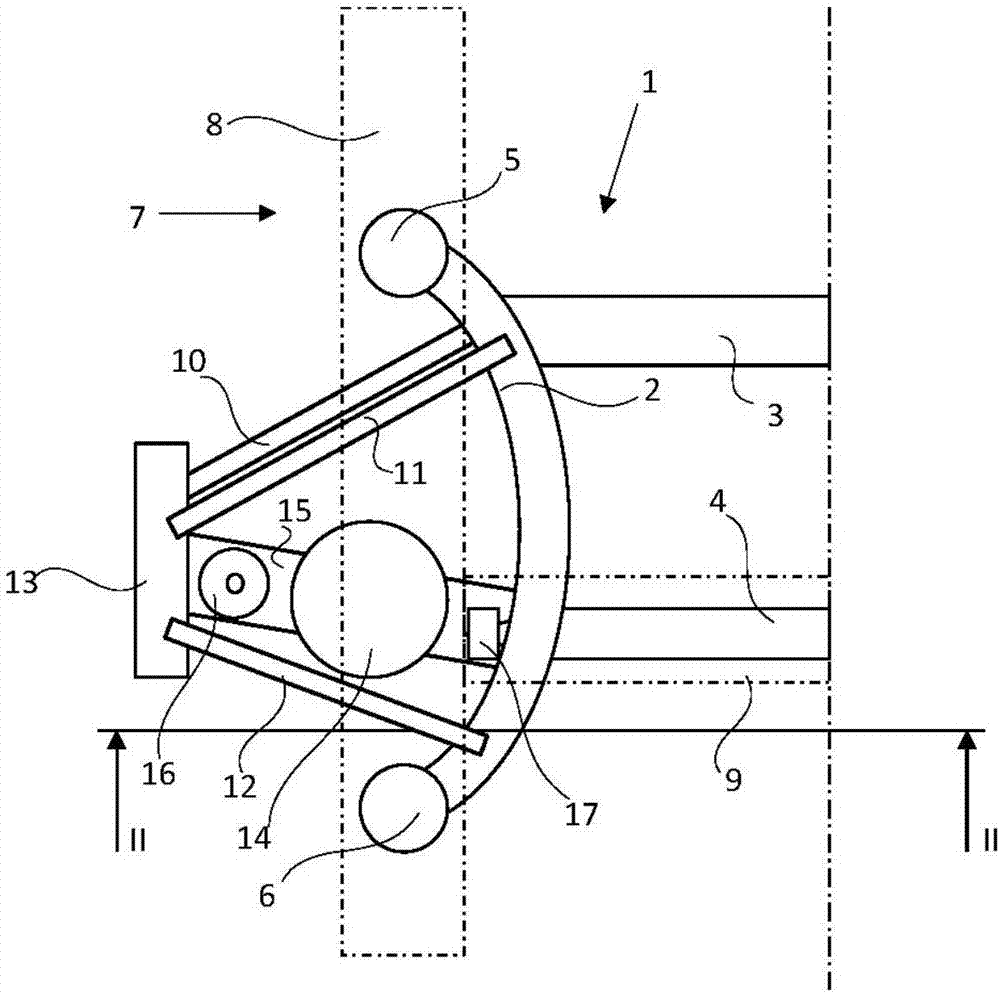

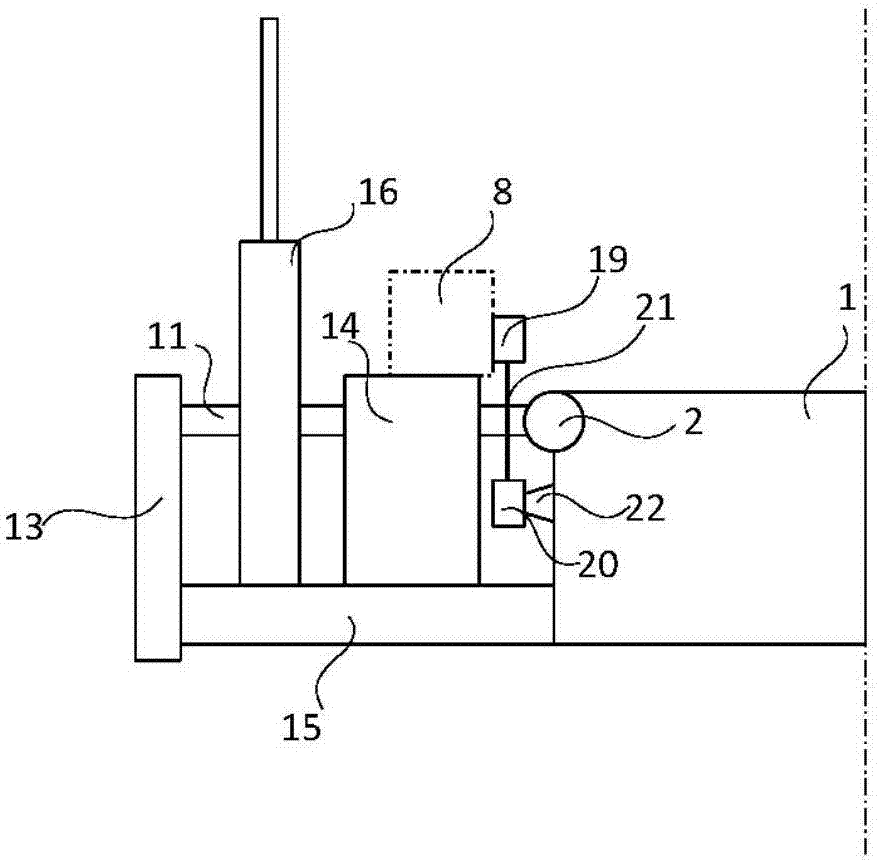

[0021] exist figure 1 with figure 2 shows a schematic and strongly simplified top view and a schematic, strongly simplified rear view, respectively, of a first embodiment of a wheel suspension system according to the invention, wherein the wheel suspension system comprises a longitudinal beam 2 and The subframe 1 of the beams 3, 4, which passes through four subframe supports - two of the four subframe supports 5, 6 are shown - and The body 7 is connected.

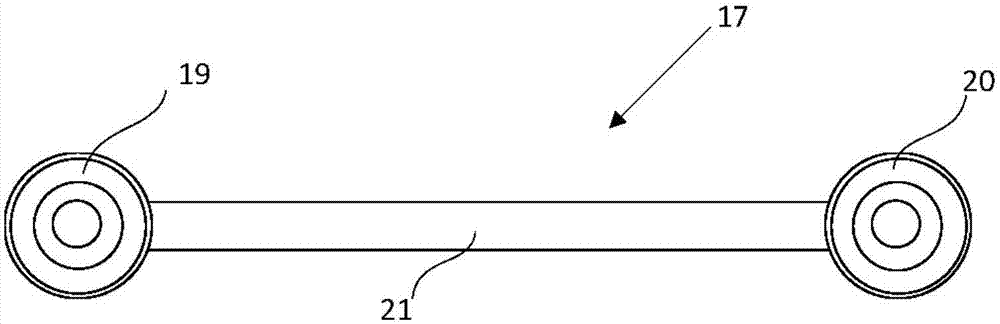

[0022] Body 7 is shown schematically by side members 8 and cross members 9 . The longitudinal members 2 of the subframe 1 are connected via a set of control arms 10 , 11 and 12 to a wheel carrier 13 in a manner known per se. The suspension spring 14 of the wheel suspension system is supported on the one hand on the spring control arm 15 on the subframe 1 and on the other hand on the vehicle body 7 . The wheel suspension system also includes a shock absorber 16 which is likewise arranged on the spring control arm 15 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com