Shale oil gas hydraulic fracturing Y-shaped fluid end

A hydraulic fracturing and shale oil and gas technology, which is applied in the direction of exploitation fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems that threaten normal construction and construction safety, harsh construction environment, and prolonged construction time, and achieve Reduce repair and maintenance time and cost, reduce repair and maintenance costs, and reduce the effect of fatigue wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

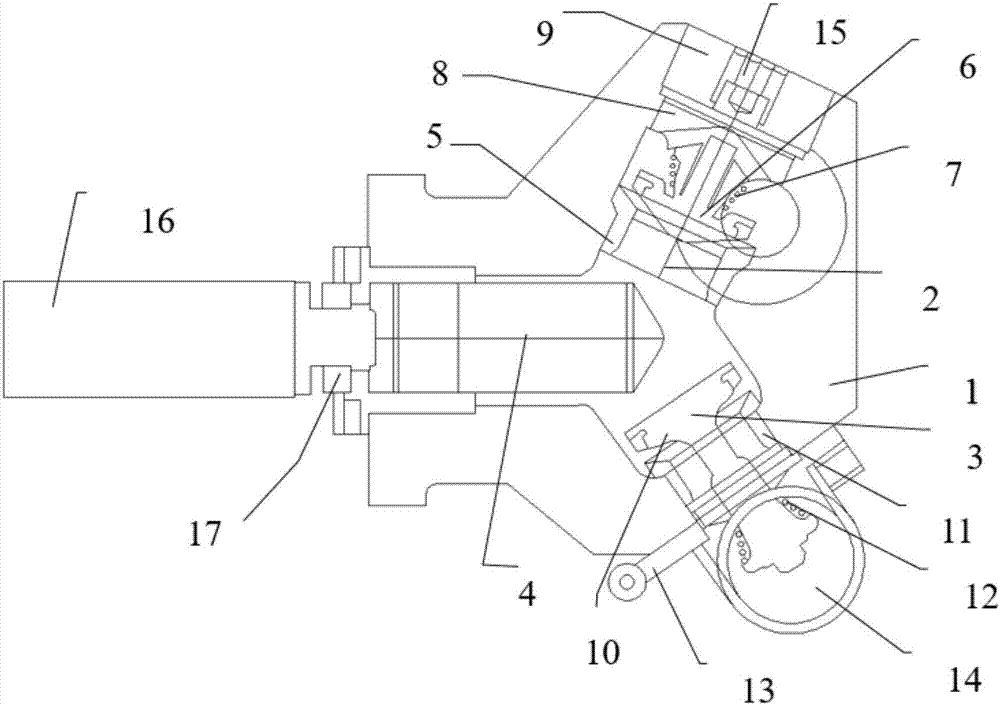

[0025] Such as figure 1 As shown, the shale oil and gas hydraulic fracturing Y-shaped hydraulic end of the present invention is mainly composed of the following parts: Y-shaped hydraulic end valve box 1, the first centerline 2, the second centerline 4, and the third centerline 3 , discharge valve seat 5, discharge valve 6, discharge spring centralizer 7, discharge plug 8, discharge pressure cap 9, suction valve 10, suction valve seat 11, suction spring centralizer 12, low pressure sand bag 13, Low-pressure liquid inlet 14, high-pressure outlet 15, plunger 16, plunger connection plate 17, discharge valve hole 18, suction valve hole 19, plunger hole 20 are formed.

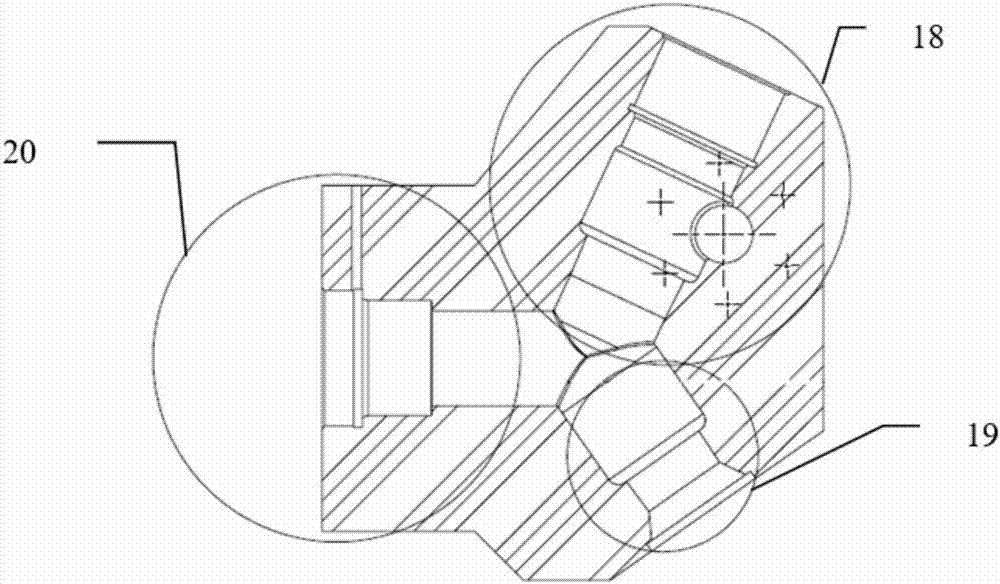

[0026] Such as figure 2 As shown, the Y-shaped fluid end valve box is formed by a discharge valve hole 18, a suction valve hole 19 and a plunger hole 20 to form a Y-shaped inner cavity.

[0027] Each Y-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com