Mining TBM chamber bottom plate hardening method

A chamber and bottom plate technology, which is applied in underground chambers, mining equipment, earthwork drilling and mining, etc., can solve the problems of heavy weight, poor bottom plate integrity, subsidence in the initial stage of the shield machine, etc., and achieve the goal of simple and practical method and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

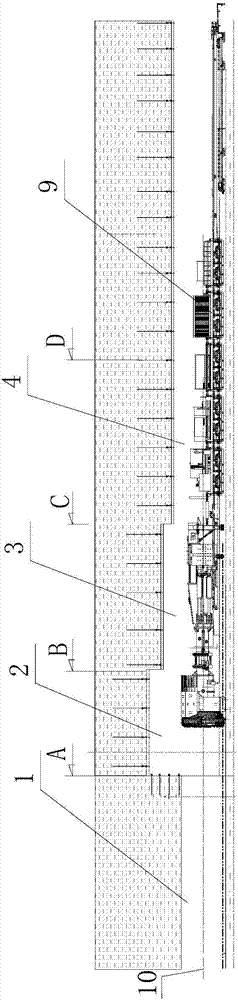

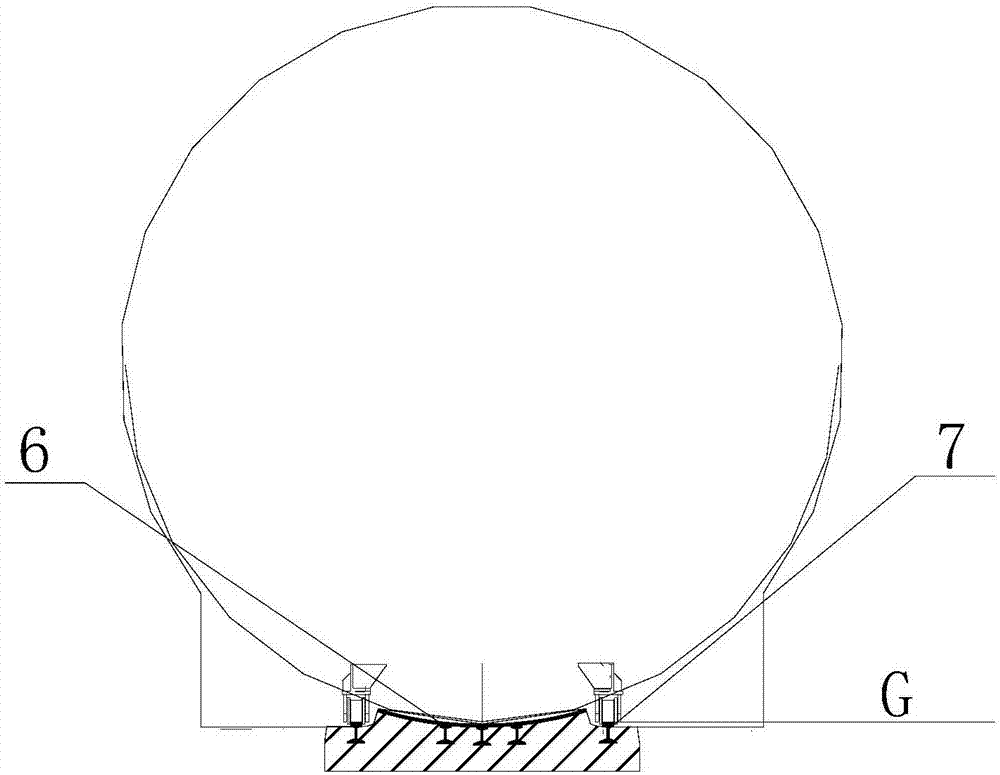

[0028] Such as Figure 1~6 As shown, this embodiment includes the following steps:

[0029] (1) The chambers along the excavation face 10 are sequentially arranged as starting chamber 1, the first assembly chamber 2, the second assembly chamber 3 and the third assembly chamber 4, in order of height from large to small: The first assembly chamber 2, the second assembly chamber 3, the third assembly chamber 4 and the starting chamber 1, the starting chamber 1, the first assembly chamber 2, the second assembly chamber 3 and the first assembly chamber The heights of the three chambers 4 are 4.6m, 7.5m, 6.2m and 5.5m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com