Core-tube-free efficient engine oil filter

A technology of oil filter and filter, which is applied in the installation/connection of lubricant purification device, lubricating parts, pressure lubricant, etc., which can solve the problems of inability to filter, limit the filter area of pleated filter paper, and weaken the filter efficiency. Achieve the effect of increasing the permeable area, simplifying the overall structure and accelerating the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the technical solution of the present invention will be described in detail through specific examples.

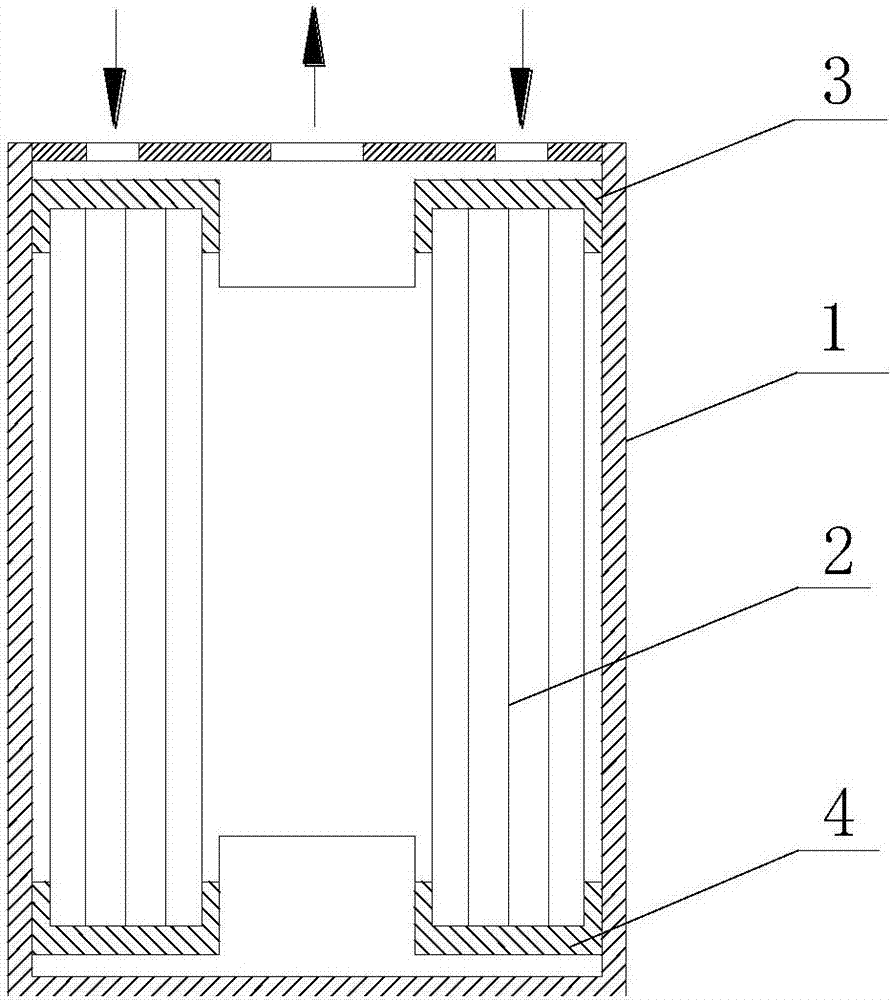

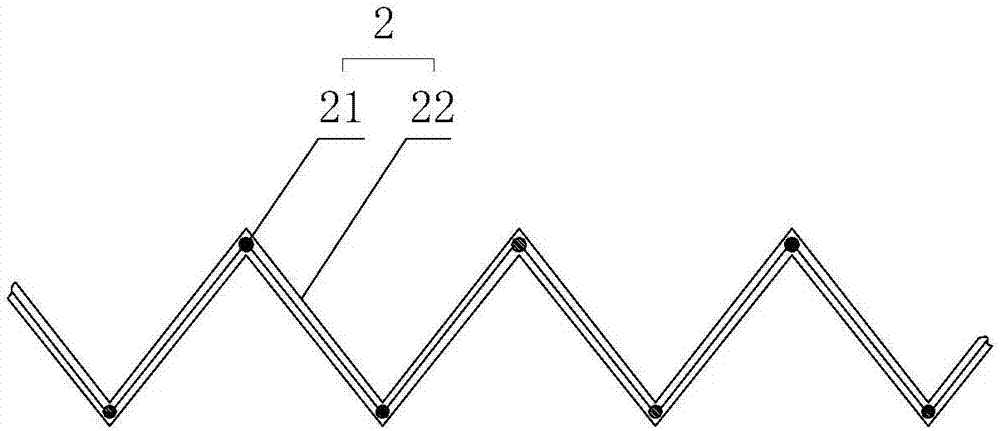

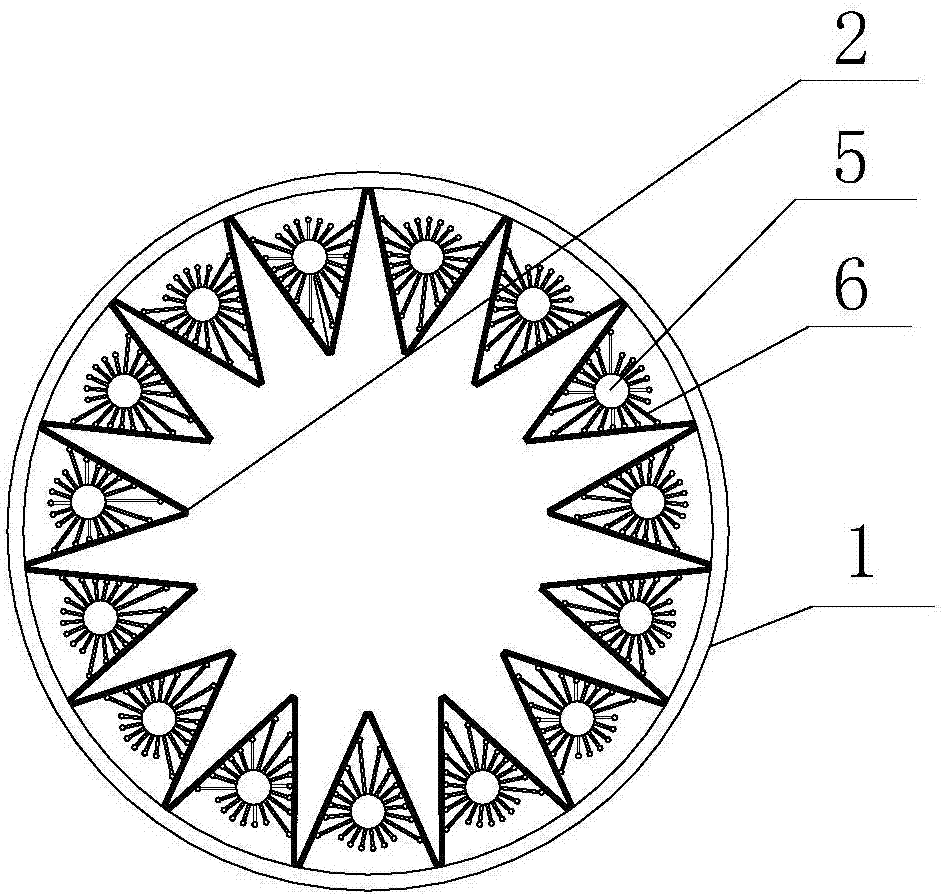

[0025] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a coreless cartridge high-efficiency oil filter proposed by the present invention; figure 2 It is a structural schematic diagram of the pleated filter paper in a coreless cylinder high-efficiency oil filter proposed by the present invention; image 3 It is a schematic diagram of the installation of the main line body in the pleated groove in a coreless cylinder high-efficiency oil filter proposed by the present invention.

[0026] refer to Figure 1-2 , a coreless cylinder high-efficiency oil filter proposed in an embodiment of the present invention, comprising: a filter body, the filter body has an oil inlet and an oil outlet, the filter body includes an outer shell 1 and is arranged on the outer shell 1 The inner filter element, the filter element includes pleated filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com