System and method for preventing overpressure of inlet of piston type compressor

A compressor and piston-type technology is applied in the field of systems and methods for preventing overpressure at the inlet of a piston-type compressor, which can solve problems such as increased operational risk, property loss, and increased labor intensity, thereby reducing design costs and reducing internal leakage. Probability, the effect of avoiding frequent jumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

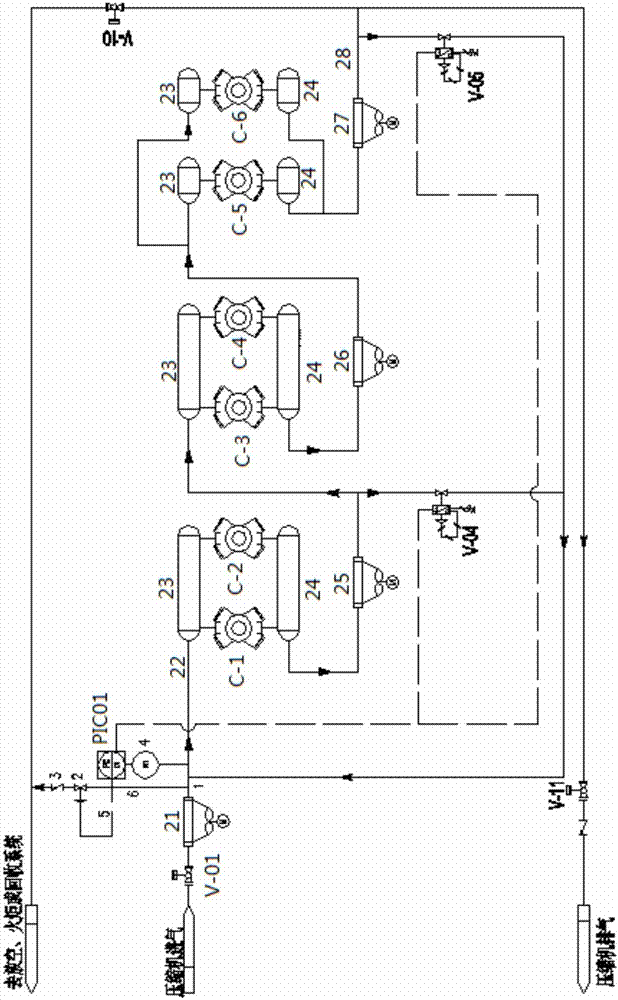

[0055] Hereinafter, this embodiment will be further described in detail with reference to the accompanying drawings.

[0056] Such as Figure 4 As shown, a system for preventing overpressure at the inlet of a piston compressor according to an embodiment of the present invention includes: between the compressor inlet ball valve V-01 or the inlet air cooler 21 and the compressor inlet 22 (or compression A branch tee 1, a connecting pipeline 6 connected to the branch tee, a pressure regulating valve 2 and a check valve arranged in sequence on the connecting pipeline 3. Pressure control circuit PIC01, the check valve 3 is further connected to the venting, flare or recovery system, the pressure control circuit includes the inlet of the compressor set on the pipeline between the air cooler and the first-stage intake buffer A pressure sensor (not shown in the figure) for detecting the inlet pressure of the compressor, a transmitter 4 connected to the pressure sensor, and a hard line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com