Long life solenoid valve started with zero pressure difference

A solenoid valve, zero-pressure technology, applied in the field of solenoid valves, can solve the problems of insufficient opening, inability to open the valve, high cost, and achieve the effects of reducing requirements and manufacturing costs, reducing load impact, and using stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

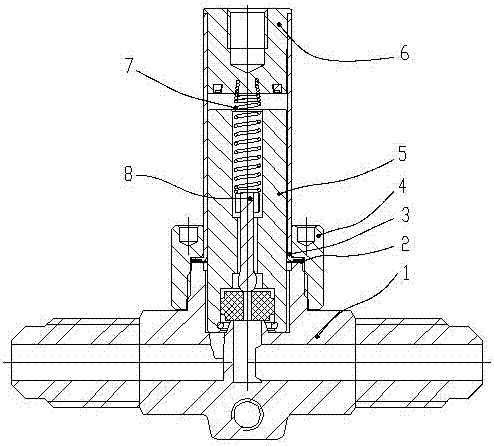

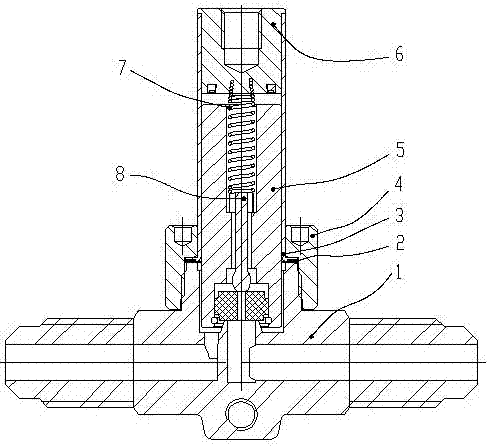

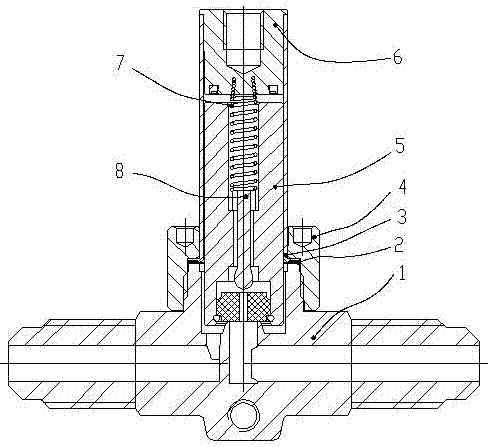

[0027] like figure 1 , figure 2 , image 3 , Figure 4 The shown solenoid valve includes a valve seat 1, a valve cover 4, a sleeve 3 fixed with the valve seat 1 and the valve cover 4 through threaded connection, and a first sealing member 2 is provided between the sleeve 3 and the valve seat 1 to seal The upper part of the casing 3 is provided with a static core iron 6, and the casing 3 and the static core iron 6 are welded and connected together; the static core iron 6 is provided with a moving core iron part 5 and a pilot part 8, and the leading part 8 is provided in the moving core iron In the inner cavity of the component 5, a return spring 7 is arranged between the pilot component 8 and the static core iron 6; the moving core iron component 5 is provided with a second sealing member 55. When the valve is closed, the lower part of the second sealing member 55 is connected to the device. The valve port 13 on the valve seat 1 is fitted and sealed, and the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com