Modular floor heating structure and construction method thereof

A modular floor heating technology, which is applied in the field of architectural decoration, can solve the problems of complex floor heating pavement, high cost, and low safety performance in use, and achieve the effect of low cost, fast laying construction, and standardized laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

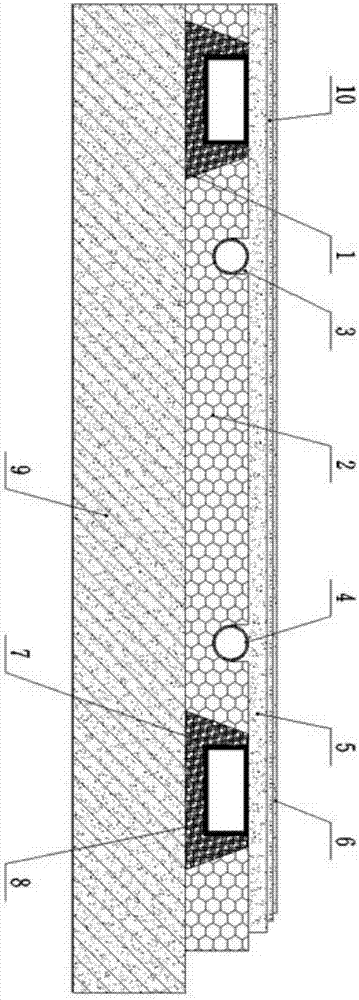

[0025] Such as figure 1 As shown, the present invention is a modular floor heating structure, a modular floor heating structure, including a bottom layer, a middle layer and an upper layer. 2 Laying at intervals; the floor heating module 2 is provided with a floor heating pipe laying groove 3, and a floor heating pipe 4 is laid in the floor heating pipe laying groove 3. The floor heating pipe 4 can be a water heating pipe or an electric heating pipe; the middle layer is laid on the bottom layer, and the middle layer is The fiber concrete board 5 is laid with an upper layer in the middle; the upper layer is a floor tile 6, and the floor tile 6 can adopt ceramic floor tiles or wooden floor tiles. Adhesive with tile glue 10.

[0026] The ground keel 1 includes a support 7 made of cement and a metal square tube 8. The support 7 is provided with a groove, and the metal square tube 8 is arranged in the groove. The support 7 is a ladder structure, and the ladder structure is mainly...

Embodiment 2

[0030] A construction method for a modular floor heating structure, comprising the steps of:

[0031] Step 1) Lay the bottom layer on the floor 9 first, and the thermal insulation module 2 is installed between two ground keels 1;

[0032] Step 2) The two ground keels are fixed and positioned by the support 7 made of fixed concrete, and the ground keel 1 and the thermal module 2 have a height difference;

[0033] Step 3) The height difference is reduced by the weight of the fiber-concrete board 5 in the middle layer, so that the thermal insulation module 2 is closely attached to the fiber-concrete board 5 in the middle layer;

[0034] Step 4) Then lay the floor heating pipe 4. After laying the floor heating pipe 4, lay the middle layer of fiber-concrete board 5, and finally lay various floor tiles 6 according to the requirements.

[0035] In the step 2), the thermal insulation module 2 is 2mm, 3mm or 5mm higher than the ground keel.

[0036] The modular floor heating structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com