Capacitor pulse voltage testing device and method

A pulse voltage and test device technology, applied in the direction of testing dielectric strength, etc., to avoid direct contact, prevent damage, and realize the effect of automatic switching control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

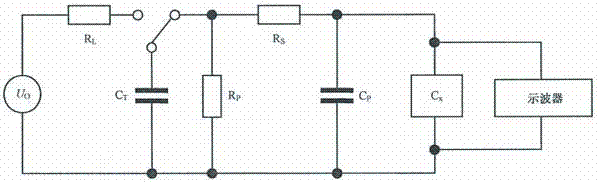

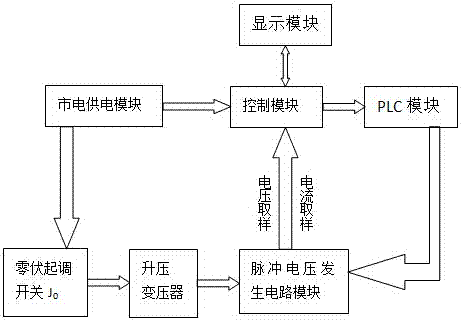

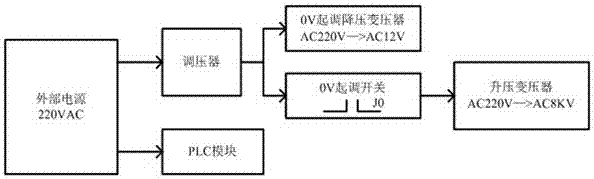

[0031] The specific implementation of the capacitor pulse voltage test device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] refer to figure 2 , discloses the capacitor pulse voltage test device, including a mains power supply circuit module for providing a power signal, a zero-volt start-up switch, a step-up transformer, a pulse voltage generation circuit module, a control module, a PLC module, and a display module; wherein , the mains power supply circuit is connected to the zero-volt starting switch in turn, and the step-up transformer is connected to the pulse voltage generating circuit module as its power input; the pulse voltage generating circuit module includes a plurality of AC contactors and generates current sampling signals and voltage sampling signals are input to the control module; the control module controls the initial working voltage, and provides initial input signals for the PLC m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com