Weld three-dimensional reconstruction method based on two-dimensional linear structured light

A linear structured light and three-dimensional reconstruction technology, which is applied in the field of welding automation to provide the basis and the field of three-dimensional reconstruction of welds, can solve the problems of low reliability, low detection and recognition efficiency, and achieve the goal of improving production efficiency, reducing labor costs, and improving competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

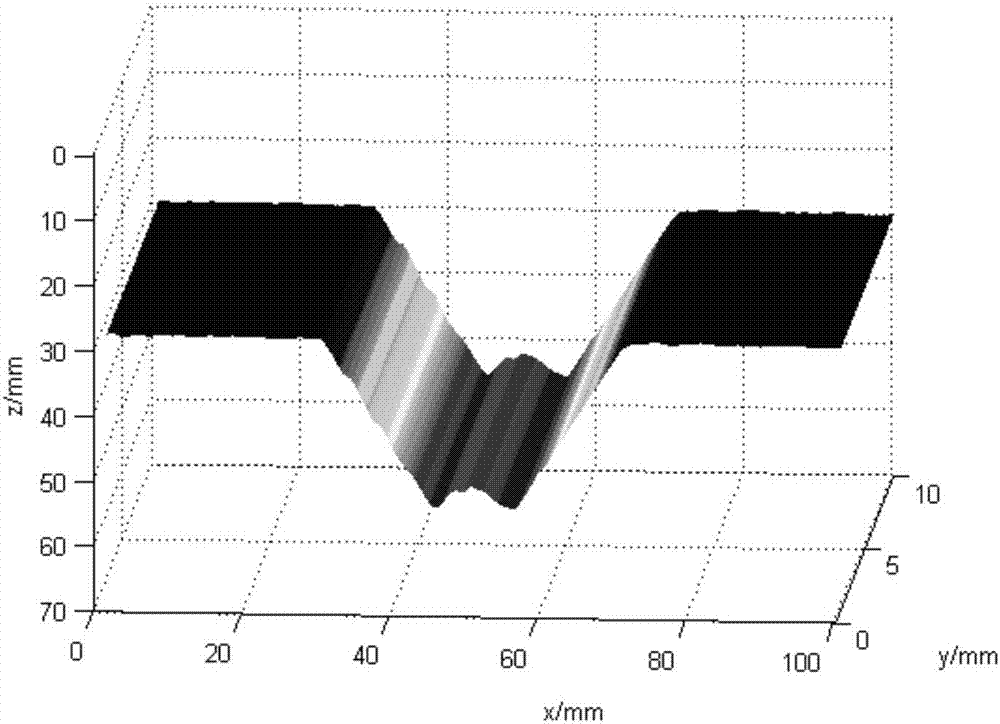

[0023] refer to figure 1 , a method for three-dimensional reconstruction of welds based on two-dimensional line structured light, the reconstruction method comprising the following steps:

[0024] (1) Weld structured light image capture and calibration

[0025] Scan along the target weld, take pictures of the target weld at regular intervals, and then acquire the two-dimensional structured light image of the target weld, and perform image calibration on the structured light image to obtain The actual length and width of a pixel in the structured light image;

[0026] (2) Weld structured light image processing

[0027] Preprocessing the two-dimensional structured light image of the weld, and then extracting the centerline of the weld by using the contour averaging method on the preprocessed structured light image to obtain the actual coordinates of each pixel of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com