Battery module

A technology for battery modules and single cells, which is applied to battery pack components, small-sized cells/battery packs, and large-sized cells/battery packs, etc. problems, to achieve the effect of simple installation structure, improved energy density, and mechanized automatic installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions, and beneficial technical effects of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described in this specification are only for explaining the present invention, not for limiting the present invention.

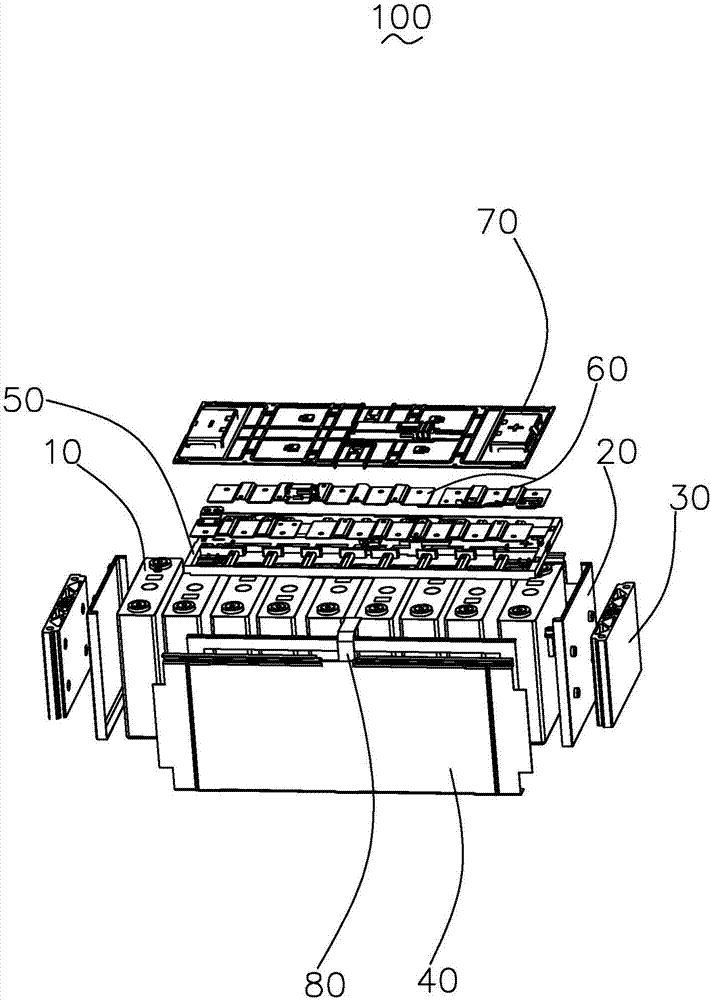

[0030] Please refer to figure 1 , The present invention provides a battery module 100, including a plurality of single cells 10, a pair of fixing frames 20, a pair of end plates 30, a pair of side plates 40, a mounting plate 50, a plurality of bus bars 60 and a protective cover 70.

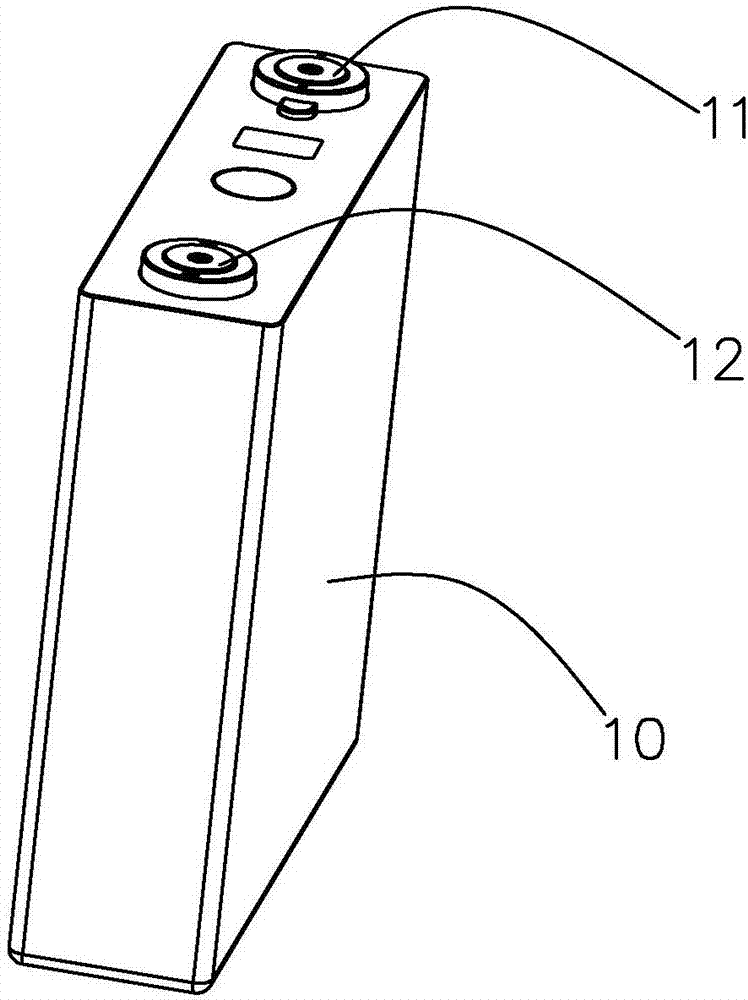

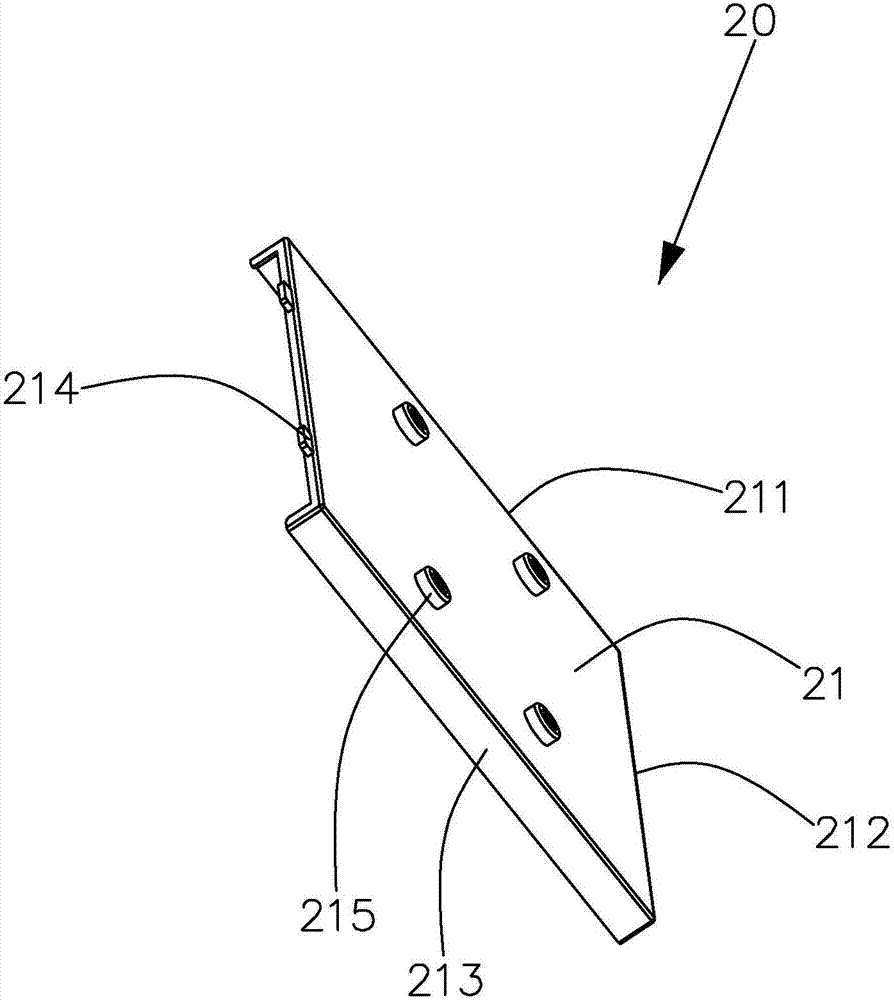

[0031] Please refer to Figure 1 to Figure 4 Each single battery 10 is in the shape of a rectangular parallelepiped, and one end of each single battery 10 is provided with a positive electrode connection port 11 and a negative electrode connection port 12, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com