Sealing method for cylindrical battery

A cylindrical battery and sealing technology, which is applied in the manufacture of primary batteries, cylindrical shell batteries/batteries, secondary batteries, etc., can solve problems such as low efficiency, high sealing edge, and no sealing size design method, so as to improve battery performance, Improve the design capacity and improve the effect of battery liquid retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

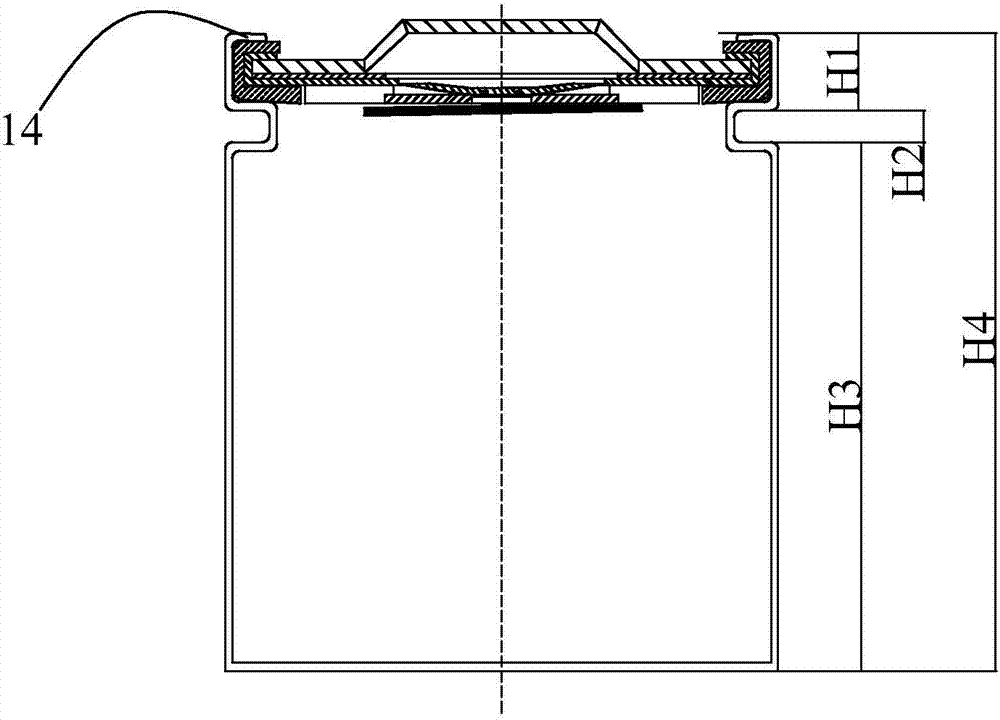

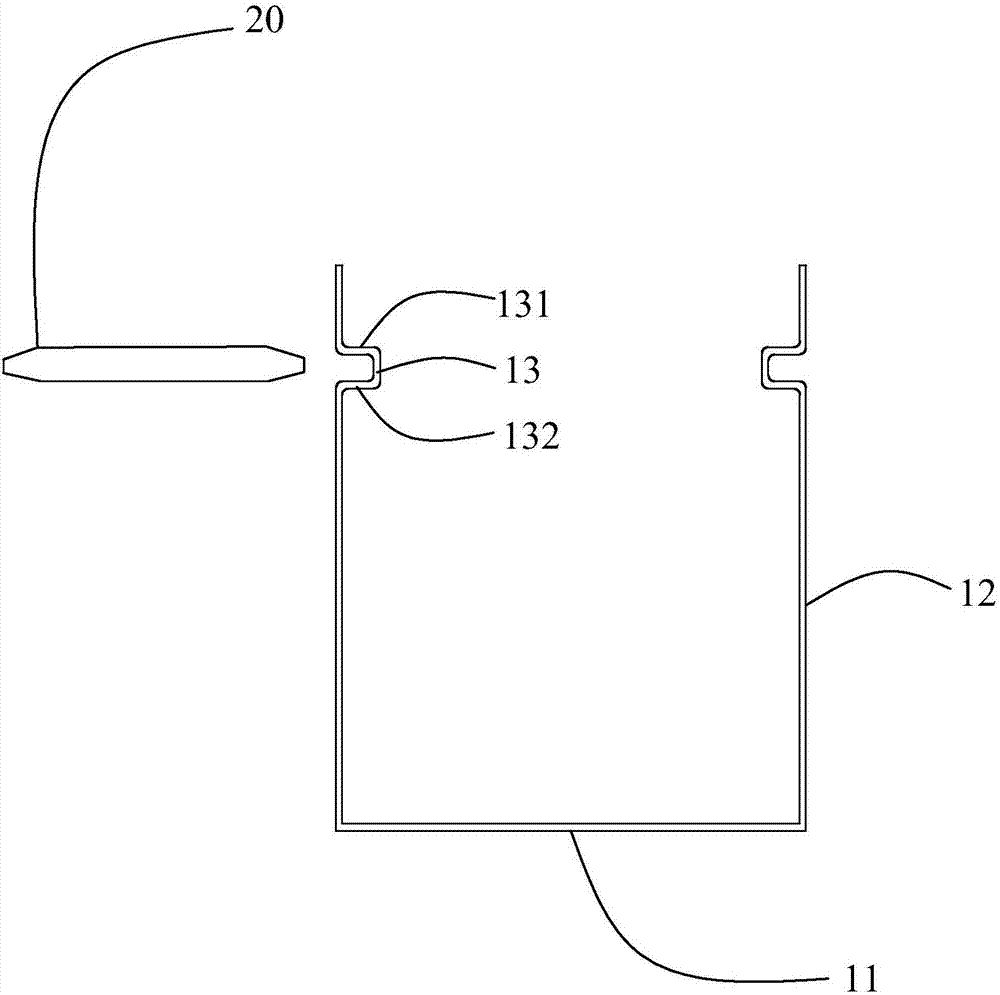

[0039] For a 32650 cylindrical battery, the wall thickness M of the steel case 10 is 0.5mm, the chamfering height h of the sealing mold 40 is 0.2mm, and the thickness L1 of the upper rubber ring part 372 is 0.7mm; The distance K is 1.75mm; the thickness L2 of the lower rubber ring part 373 is 0.7mm; the compression rate of the upper rubber ring part 372 and the lower rubber ring part 373 is 50%; adopt the sealing method of the present invention, the second bottom wall 131 and the described The distance H1 between the two opposite surfaces of the inner edge 14 = 2×0.5+0.2+0.7×(1-50%)+1.75+0.7×(1-50%)=3.65mm.

[0040] The thickness N of the hob 20 is 1.5 mm, and the distance H2 between the opposite surfaces of the second bottom wall 131 and the third bottom wall 132 of the groove 13 is equal to the thickness N of the hob, which is 1.5 mm.

[0041] The distance from the surface of the first bottom wall 11 opposite to the inner edge 14 to the surface of the third bottom wall 132 o...

Embodiment 2

[0043] For a 32650 cylindrical battery, the wall thickness M of the steel case 10 is 0.5mm, the chamfering height h of the sealing mold 40 is 0.2mm, and the thickness L1 of the upper rubber ring part 372 is 0.7mm; The distance K is 1.75mm; the thickness L2 of the lower rubber ring part 373 is 0.7mm; the compression rate of the upper rubber ring part 372 and the lower rubber ring part 373 is 70%; adopt the sealing method of the present invention, the second bottom wall 131 and the described The distance H1 between the two opposite surfaces of the inner edge 14 = 2×0.5+0.2+0.7×(1-70%)+1.75+0.7×(1-70%)=3.37mm.

[0044] The thickness N of the hob 20 is 1.5 mm, and the distance H2 between the opposite surfaces of the second bottom wall 131 and the third bottom wall 132 of the groove 13 is equal to the thickness N of the hob, which is 1.5 mm.

[0045] The distance from the surface of the first bottom wall 11 opposite to the inner edge 14 to the surface of the third bottom wall 132 o...

Embodiment 3

[0047] For a 32650 cylindrical battery, the wall thickness M of the steel case 10 is 0.5mm, the chamfering height h of the sealing mold 40 is 0.2mm, and the thickness L1 of the upper rubber ring part 372 is 0.7mm; The distance K is 1.75mm; the thickness L2 of the lower rubber ring part 373 is 0.7mm; the compression rate of the upper rubber ring part 372 and the lower rubber ring part 373 is 70%; adopt the sealing method of the present invention, the second bottom wall 131 and the described The distance H1 between the two opposite surfaces of the inner edge 14 = 2×0.5+0.2+0.7×(1-70%)+1.75+0.7×(1-70%)=3.37mm.

[0048] The thickness N of the hob 20 is 1.2 mm, and the distance H2 between the opposite surfaces of the second bottom wall 131 and the third bottom wall 132 of the groove 13 is equal to the thickness N of the hob, which is 1.2 mm.

[0049] The distance from the surface of the first bottom wall 11 opposite to the inner edge 14 to the surface of the third bottom wall 132 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com