Charging and discharging circuit based on half-bridge structure, and method

A charge-discharge circuit, charge-discharge technology, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of affecting sampling accuracy, temperature drift, voltage breakdown, etc., to increase stability and reliability, reduce Small ripple amplitude, the effect of reducing performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific implementation of the charging and discharging circuit and method based on the half-bridge structure of the present invention will be described in detail below with reference to the accompanying drawings.

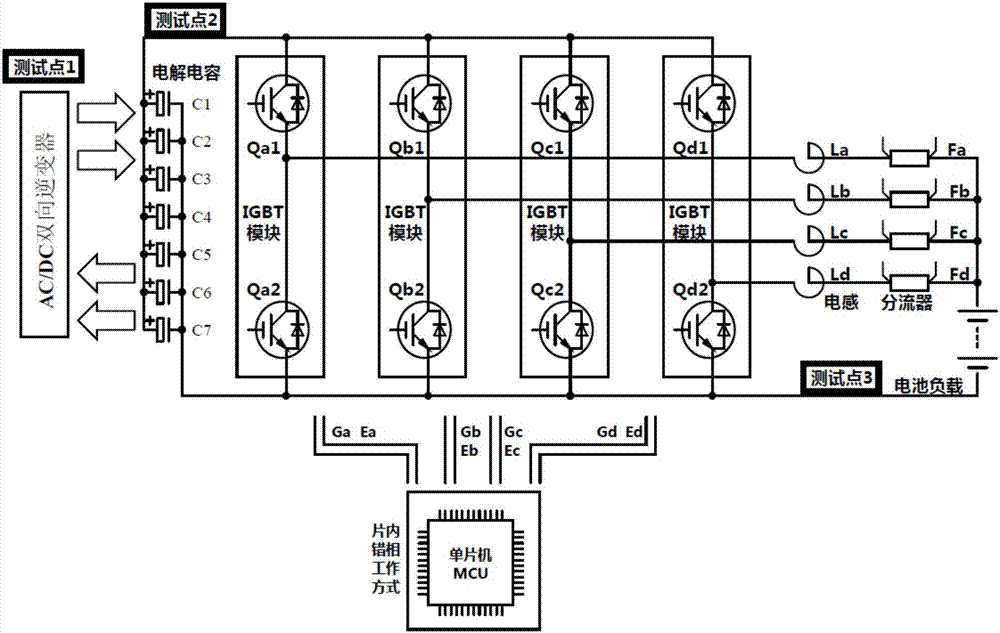

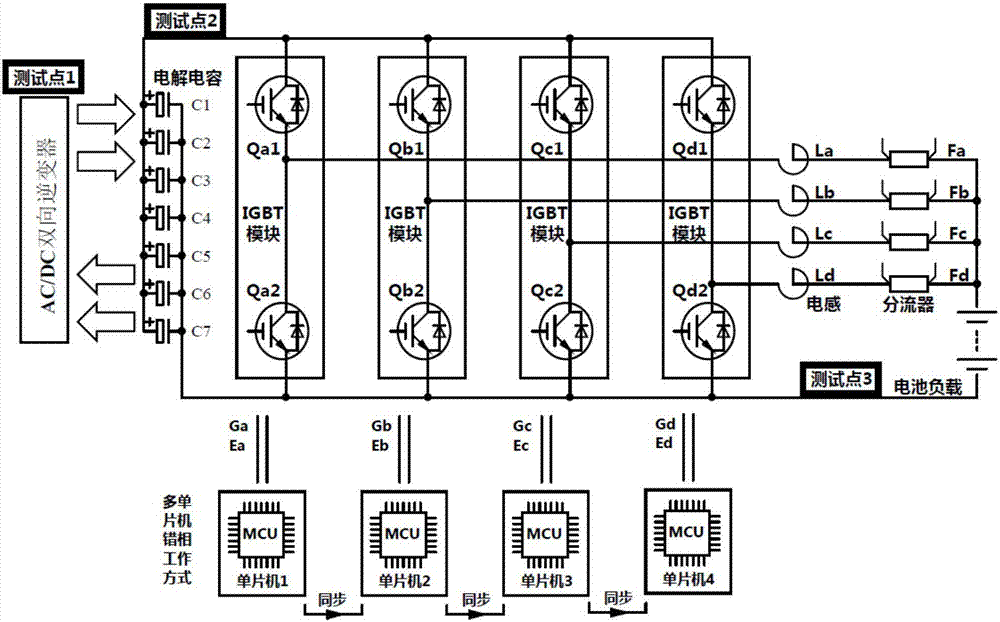

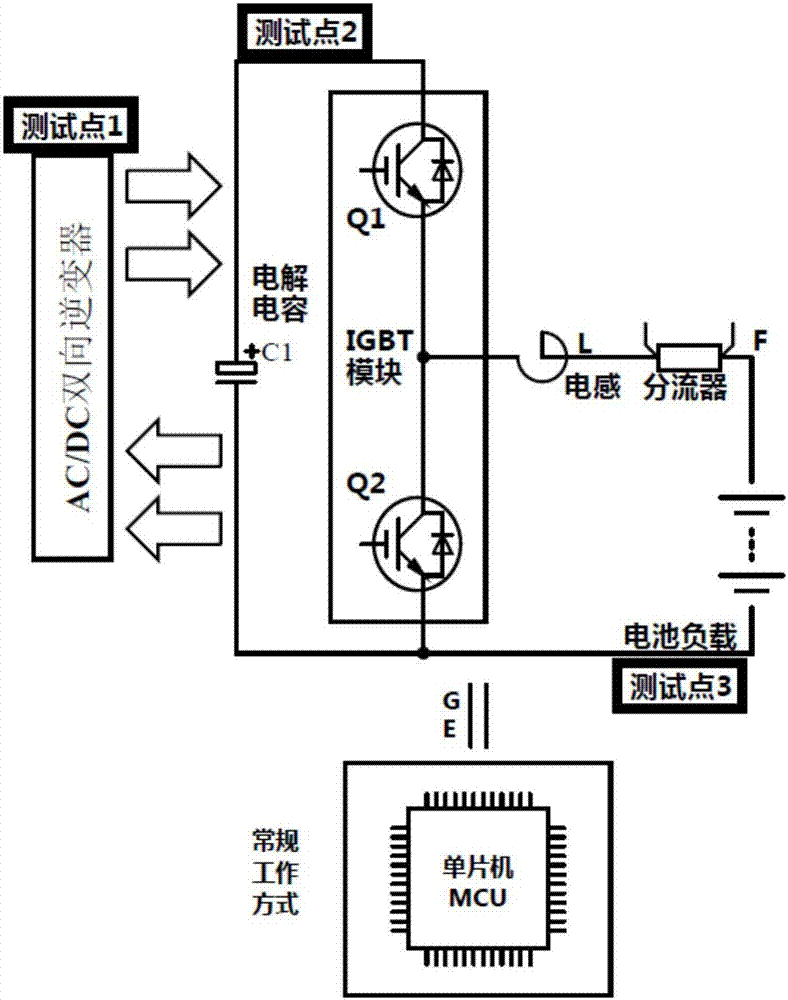

[0017] Such as figure 1 As shown, the charging and discharging circuit based on the half-bridge structure using on-chip wrong-phase drive (a single-chip microcomputer), including: AC / DC bidirectional inverter, bus filter connected in parallel on the DC output of the AC / DC bidirectional inverter circuit, and four charging and discharging units connected in parallel (the number of charging and discharging units can be determined according to the actual situation, and can also be three or five or even more), and the phase angles provided for these four charging and discharging units are mutually Staggered PWM out-of-phase drive circuit (since it is four-way out-of-phase output, the phase angles of the sequential outputs differ by 90 degrees), the bus filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com