Integrated molding three-dimensional shoe upper molding technology

A molding process and shoe upper technology, which is applied to shoe uppers, footwear, boot legs, etc., can solve the problems of low production efficiency, many process links, and high rejection rate, and achieve high work efficiency, good air permeability, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

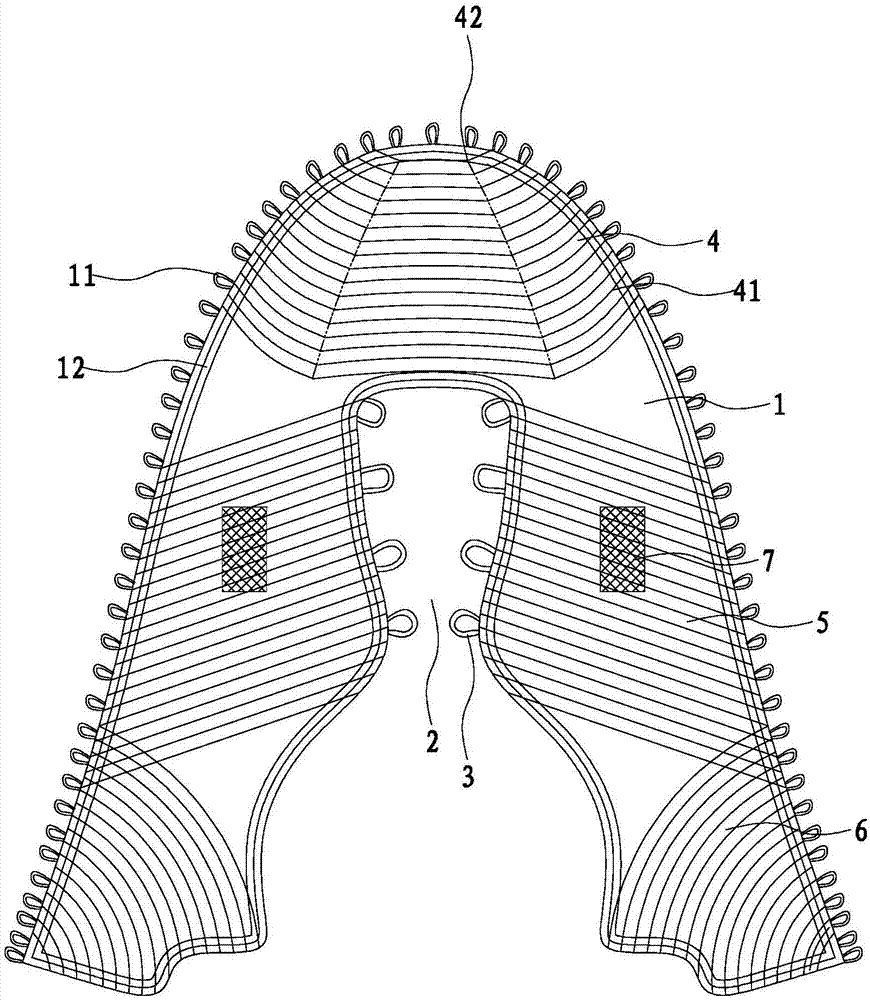

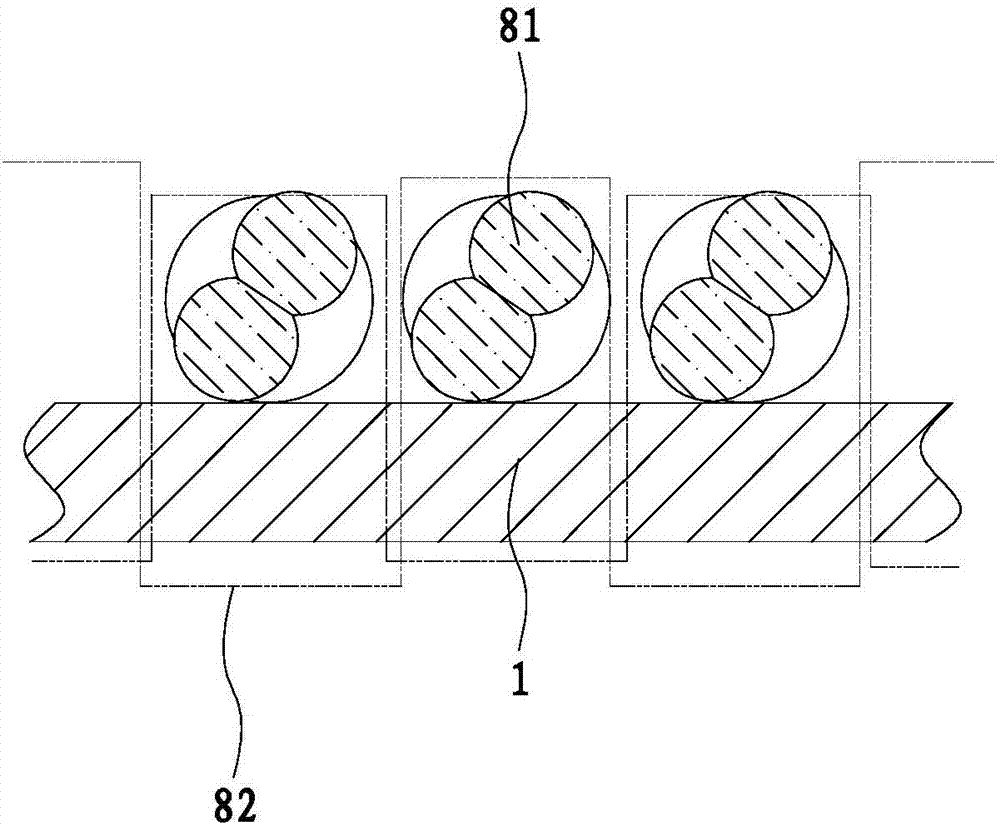

[0022] refer to figure 1 , figure 2 , this embodiment provides an integrally formed three-dimensional vamp, including a base layer 1, a tongue opening 2 provided in the middle of the base layer 1 for installing a tongue, the base layer 1 is formed by weaving threads, the A plurality of piercing rings 3 formed by protruding lines are arranged on the periphery of the tongue mouth 2, and a plurality of linear reserved rings 11 are arranged on the outer edge of the vamp, and the linear reserved rings 11 are actually related to the threaded The ring 3 is similar, and its function is to prevent the thread of the base layer 1 from loosening. The front end of the base layer 1 is superimposed with five layers of textile layers 4 by thread weaving. The threads of the textile layer 4 are formed from the tongue mouth 2 to the front end of the upper. A plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com