Automatic spraying system

An automatic spraying and nozzle technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of reducing production efficiency, existence of dead ends, poor cleaning effect, etc. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

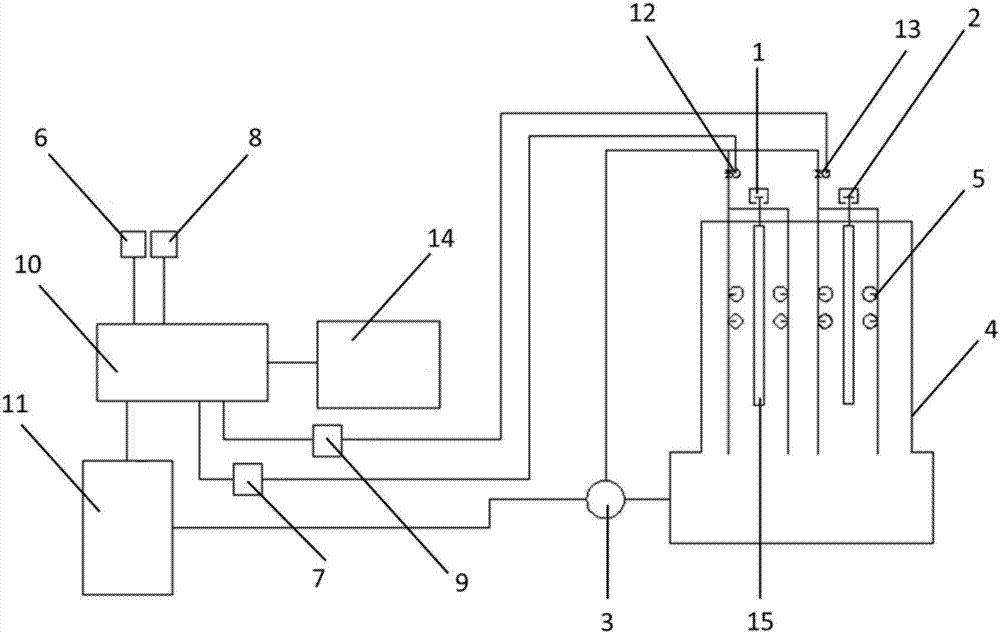

[0053] When the first intermediate relay 6 detects that the first conveying chain 1 is running, the first intermediate relay 6 sends the operating status to the core controller 10; when the third intermediate relay 8 detects that the second conveying chain 2 is not in operation, the third intermediate The relay 8 sends the shutdown status to the core controller 10 .

[0054] At this time, the core controller 10 controls the frequency converter 11 to output a low operating speed and controls the frequency converter 11 to turn on the pump 3 according to the received operating information of the first conveying chain 1 and the second conveying chain 2. At the same time, the core controller 10 controls the first The second intermediate relay 7 opens the first electric valve 12 . The pump 3 drives the cleaning agent into the pipeline 4, the cleaning agent flows into the nozzle 5 through the first electric valve 12 and is sprayed out from the nozzle 5, and is sprayed on the aluminum...

Embodiment 2

[0056] When the first intermediate relay 6 detects that the first conveyor chain 1 is running, the first intermediate relay 6 sends the running state to the core controller 10; when the third intermediate relay 8 detects that the second conveyor chain 2 is also in the running state, the second The three intermediate relays 8 send the running status to the core controller 10 .

[0057] At this time, when the core controller 10 receives the information that both the first conveying chain 1 and the second conveying chain 2 are in the running state, the core controller 10 controls the frequency converter 11 to output a high operating speed and controls the frequency converter 11 to turn on the pump 3 , at the same time, the core controller 10 controls the second intermediate relay 7 to open the first electric valve 12 , and controls the fourth intermediate relay 9 to open the second electric valve 13 . The pump 3 drives the cleaning agent into the pipeline 4, and the cleaning agen...

Embodiment 3

[0059]When the first intermediate relay 6 and the third intermediate relay 8 detect that the first conveying chain 1 and the second conveying chain are in the state of stopping operation, the first intermediate relay 6 and the third intermediate relay 8 send the stop operation information to the core control device 10;

[0060] The core controller 10 controls the frequency converter 11 to turn off the pump 3 , and the pump 3 stops driving the cleaning agent into the pipeline 4 . At the same time, the core controller 10 controls the second intermediate relay 7 and the fourth intermediate relay 9 to close the first electric valve 12 and the second electric valve 13 respectively. The first electric valve 12 and the second electric valve 13 block the cleaning agent remaining in the pipeline 4 from entering the nozzle 5 and spraying out.

[0061] Using the automatic spraying system provided by the present invention, the cleaning agent is sprayed onto the aluminum alloy profile 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com