Dispersion stabilizer and application thereof

A dispersion stabilizer and diffusion agent technology, applied in the field of textile printing and dyeing, can solve the problems of increasing the input ratio of dyeing auxiliaries, failing to realize zero discharge of waste water, and failing to obtain actual benefits, so as to avoid toxic and carcinogenic ingredients, improve Washing and bleaching problems, the effect of improving vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the dispersion stabilizer that different proportioning forms

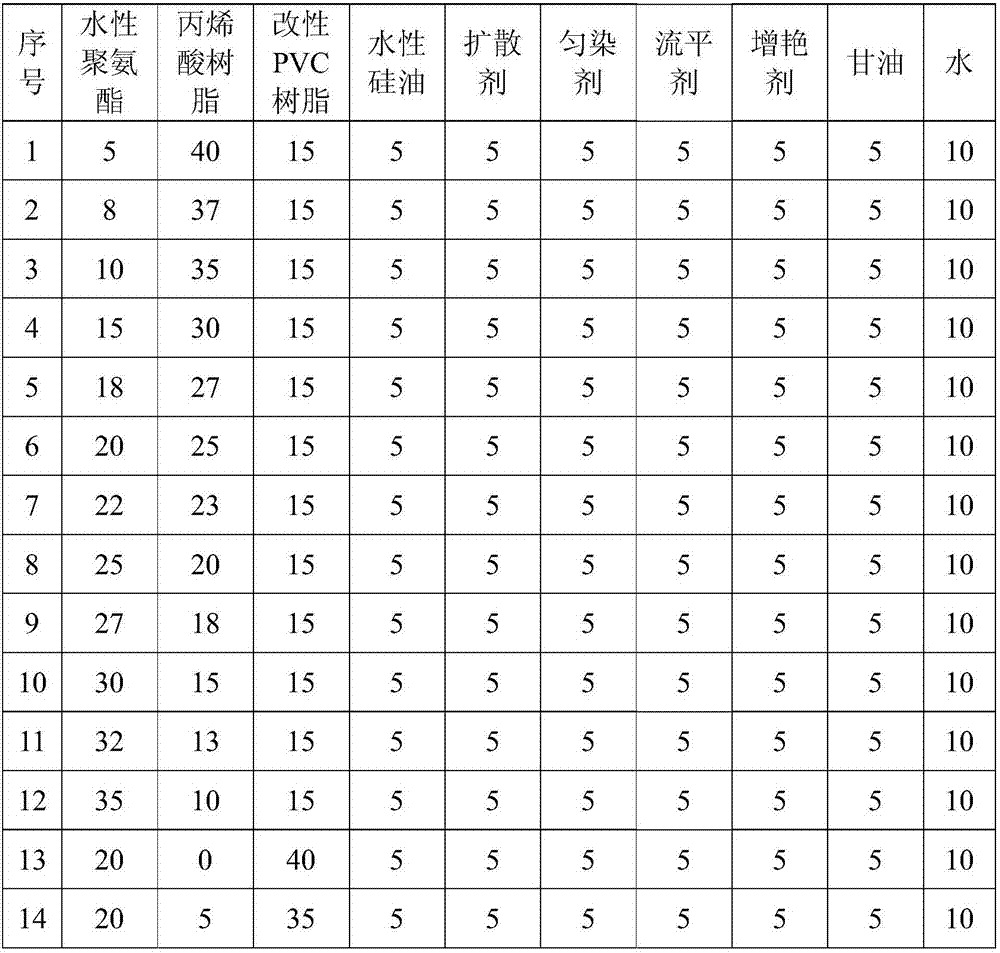

[0020] This embodiment is a kind of dispersion stabilizer, and its formula is shown in Table 1.

[0021] The dispersion stabilizer (unit, %) of different proportioning of table 1

[0022]

[0023]

[0024] In this embodiment, water-based polyurethane, acrylic resin and modified PVC resin are used as water-based functional resin components, and the relationship between the three components is proportioned in Table 1, and the water-based silicone oil, diffusing agent , leveling agent, leveling agent, brightening agent, glycerin and water are used as quantitative components, and the pH of the formed dispersion stabilizer is controlled to be 6-7, and the influence of water-based functional resin components on the dispersion stabilizer is tested.

[0025] Apply it to printing or dyeing, the process is pulping→dyeing or printing→steaming, in which, in the pulping process, dye 1-3%, thickener 1...

Embodiment 2

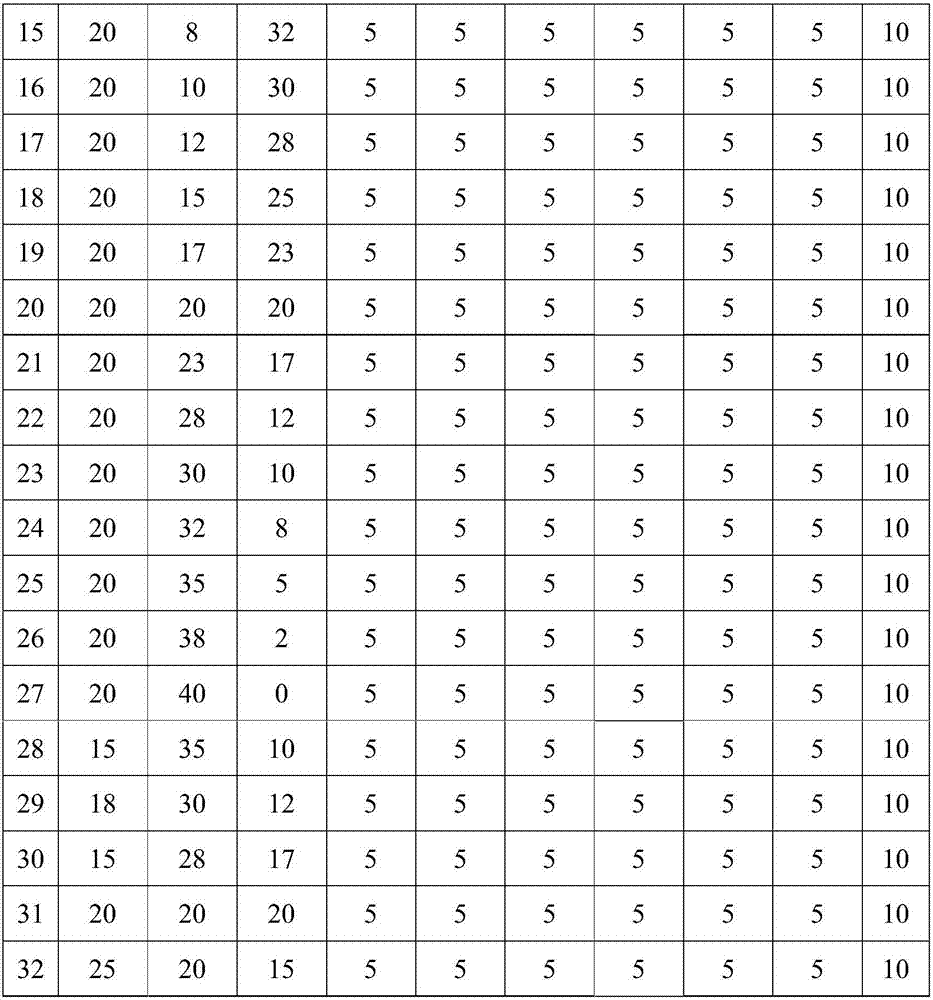

[0030] Embodiment 2: the impact of different proportioning slurry on dyeing

[0031]The dispersion stabilizer corresponding to No. 6 in Table 1 used in this embodiment is used for dyeing. The dispersion stabilizer is composed of: 20% water-based polyurethane, 25% acrylic resin, 15% modified PVC resin, 5% water-based silicone oil, diffusion 5% dyeing agent, 5% leveling agent, 5% leveling agent, 5% brightening agent, 5% glycerin, 10% pure water, apply it to dyeing or printing, the process is: pulping → dyeing or printing →Steaming, wherein, in the slurry preparation process, the composition of the color paste is as shown in Table 2 (the present embodiment takes disperse dyes as a representative to carry out the statement of the scheme).

[0032] Table 2 Color pastes with different compositions (unit, %, water makes up 100%, so it is not listed in Table 2)

[0033] serial number dye thickener Emulsifier dispersion stabilizer softener 1 0.05 3 1 5 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com