Hand wheel clutch for machine

A technology of clutches and handwheels, which is applied in the direction of mechanically driven clutches, clutches, and clutches that mesh with each other, and can solve problems such as difficult maintenance, difficult assembly, and increased processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

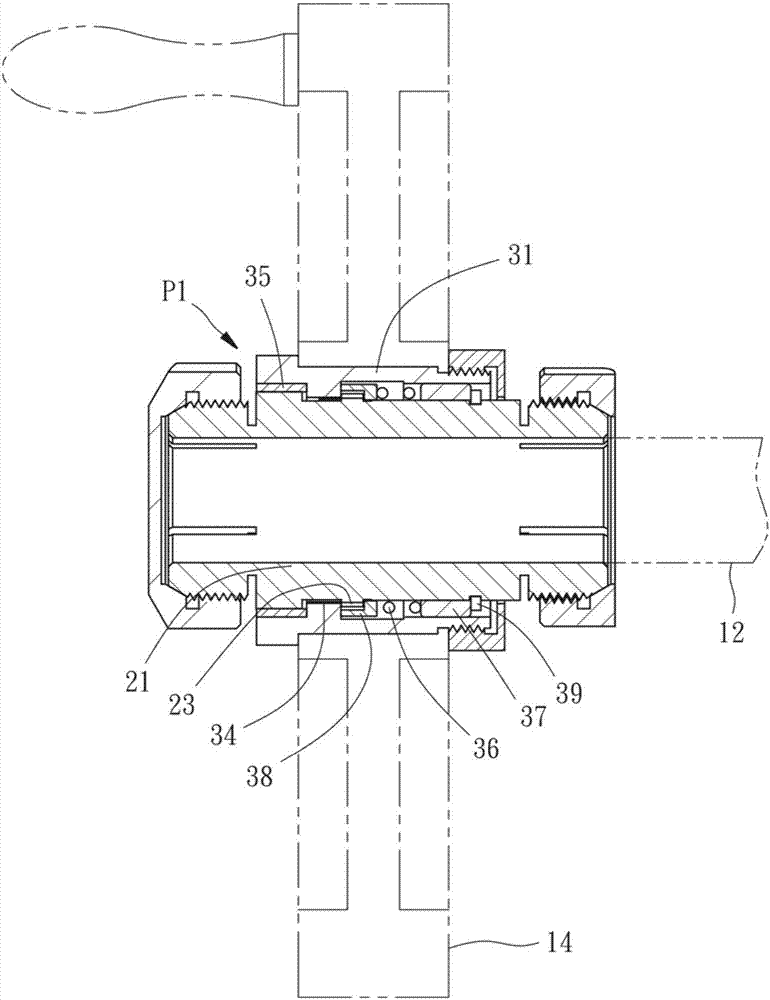

[0026] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

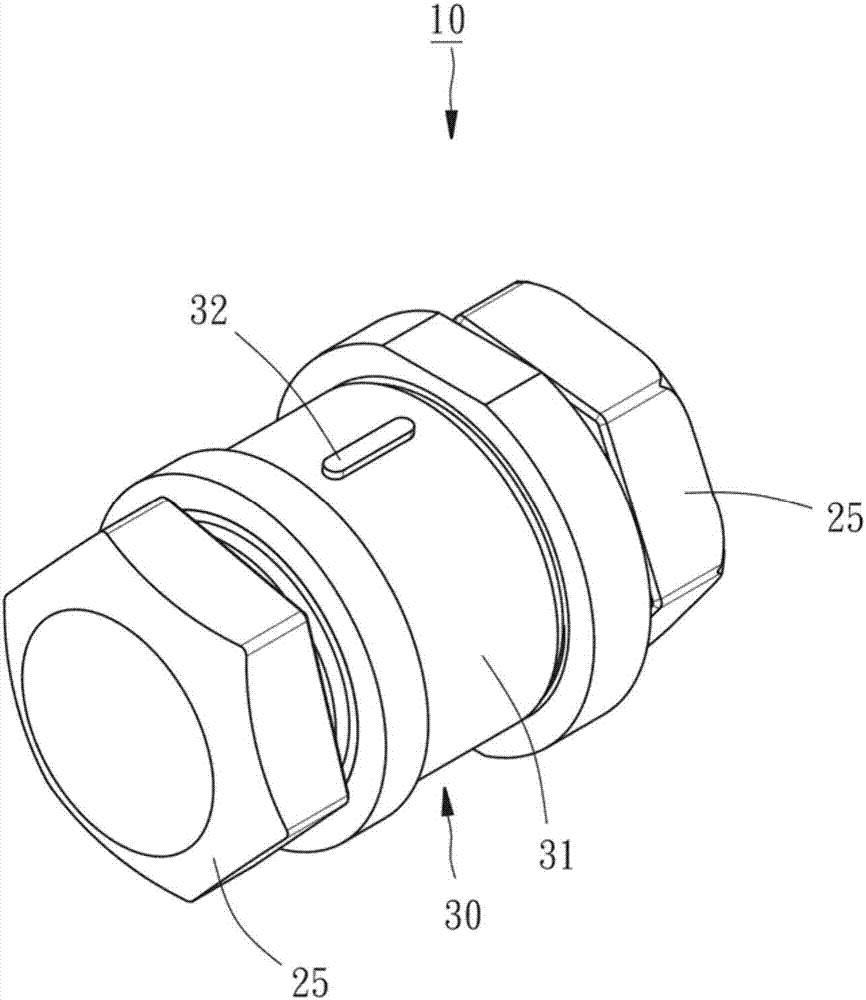

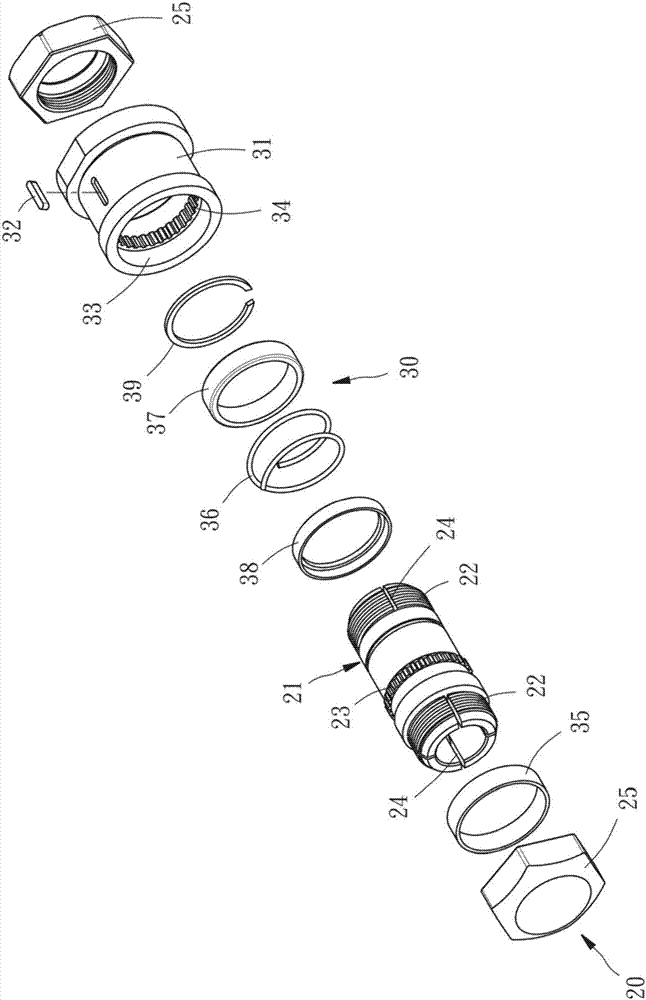

[0027] see figure 1 and 2 , the handwheel clutch 10 for machinery of the present invention includes a handwheel fixing unit 20 and a clutch unit 30 .

[0028] The handwheel fixing unit 20 has a shaft sleeve 21 and two nuts 25, wherein the shaft sleeve 21 is used to be sleeved on a handwheel shaft 12 (such as image 3 shown). Both ends of the shaft sleeve 21 have an external thread portion 22 respectively, and the outer peripheral surface of the shaft sleeve 21 has an outer ring tooth portion 23, and the outer ring tooth portion 23 is interposed between the two external thread portions 22; each nut 25 The screw is arranged on the external thread portion 22 of the shaft sleeve 21 , thereby, when the shaft sleeve 21 is sleeved on the handwheel shaft 12 and then the nut 25 is locked, the shaft sleeve 21 and the handwheel shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com