A silkworm cocoon de-clustering machine

A technology of silkworm cocoons and racks, applied in the field of silkworm cocoon declustering machines, can solve the problems of impossible one-time pouring of silkworm cocoons, low work efficiency, large workload, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

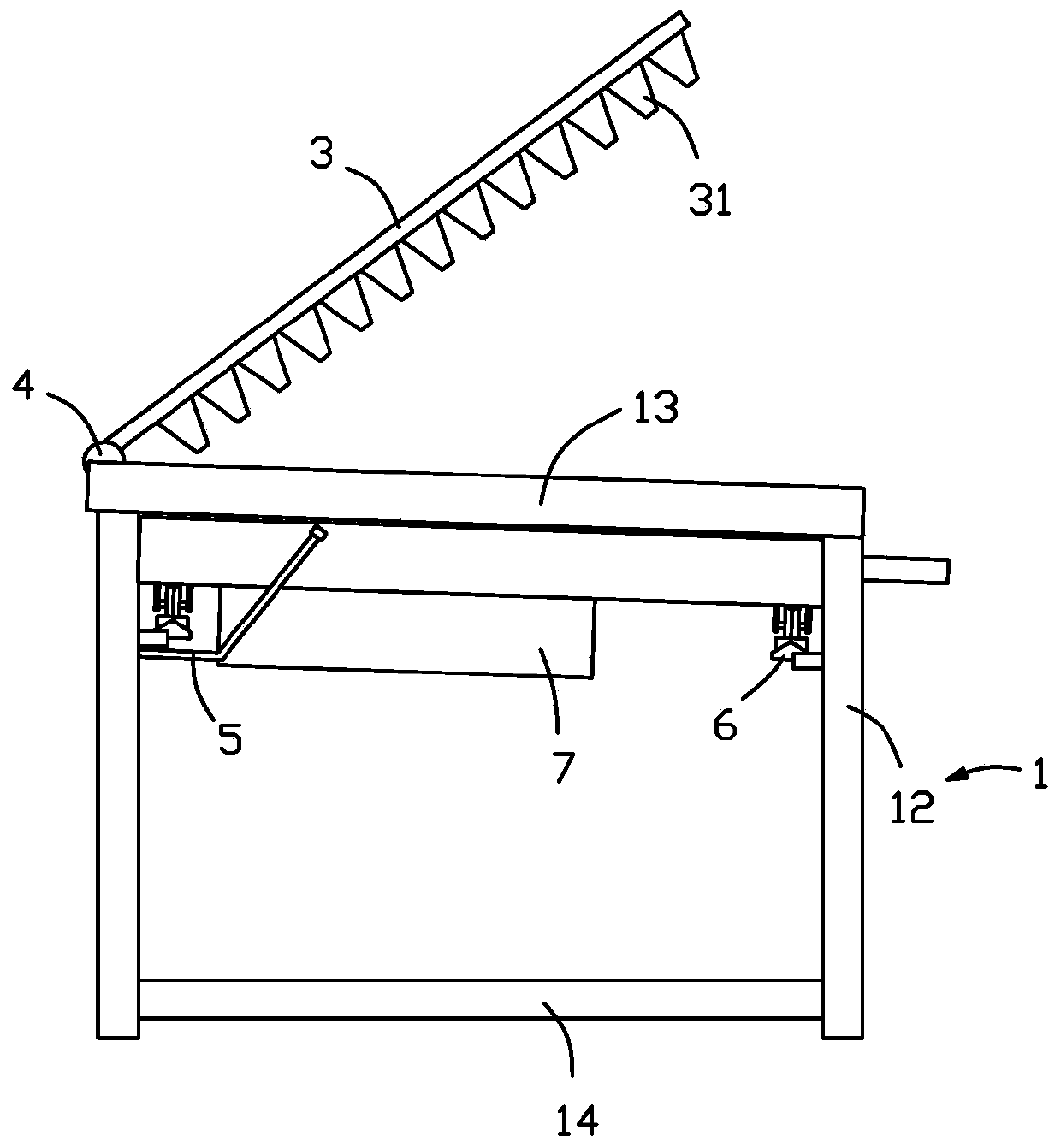

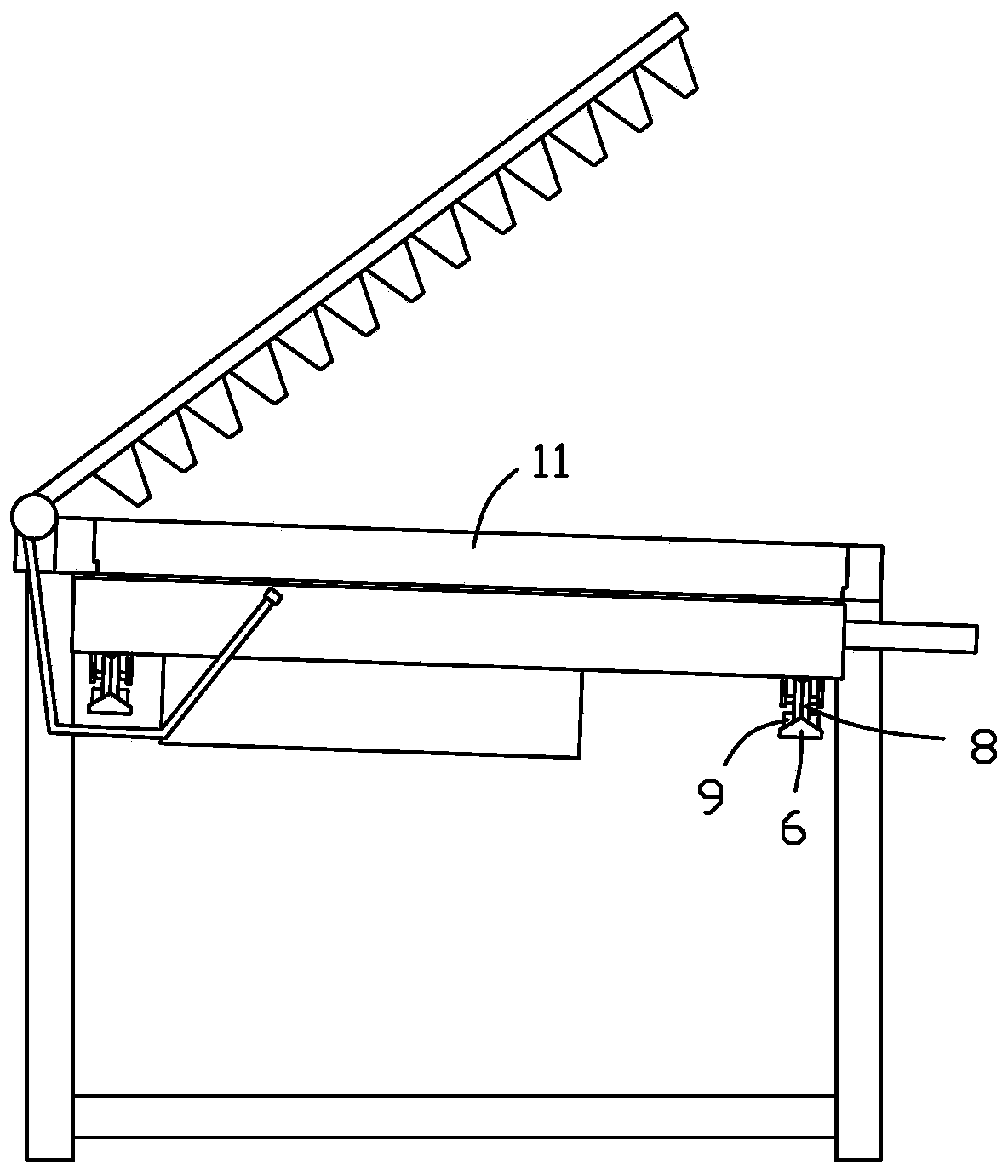

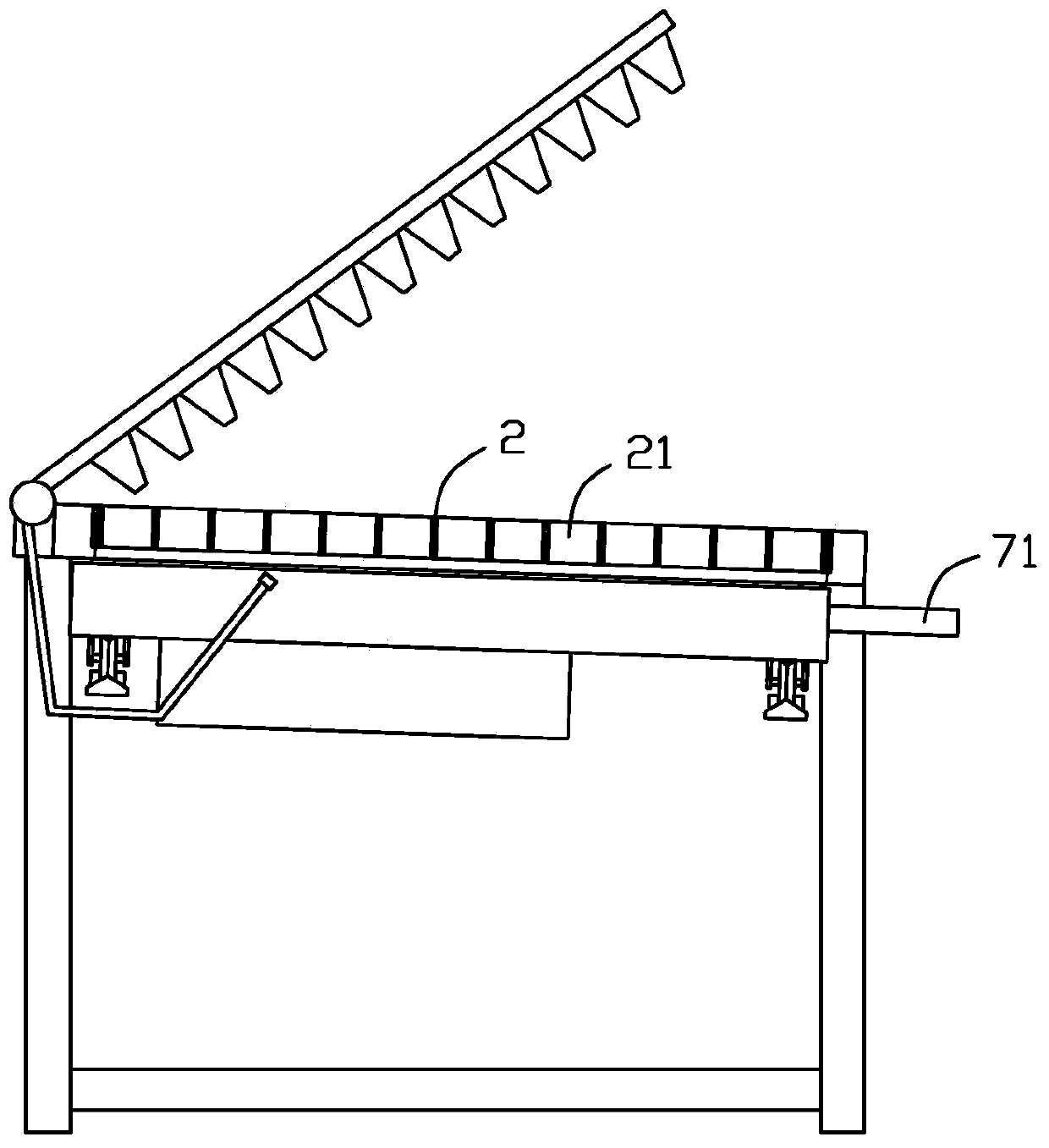

[0024] see Figure 1 to Figure 4 , In a preferred embodiment of the present invention, a silkworm cocoon de-clustering machine includes a frame 1, an extrusion frame 3 and a pushing scraping frame 7. The top of the frame 1 is provided with an accommodating opening 11 for placing the grid cluster 2, and an extruding frame 3 is arranged on one side of the accommodating port 11, and the extruding frame 3 is rotatably installed on a top of the frame 1 through an overturning shaft 4. At the edge, it can be flipped relative to the frame 1 to cover or open the accommodating opening 11 . On the side of the extruding frame 3 facing the accommodating opening 11, several extruding columns 31 are arranged at intervals. The extruding columns 31 correspond to the square holes 21 on the square cluster 2 one by one, and are covered and accommodated on the extruding frame 3. When the mouth 11 is inserted into the grid hole 21 of the grid cluster 2; the turning shaft 4 is sleeved with a torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com