System and method applied to automatic brazing of stellite alloy long blades

A long blade, brazing technology, applied in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of poor consistency of brazing quality of each blade, low brazing pass rate, etc., to improve the pass rate And brazing quality, strong practicability, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

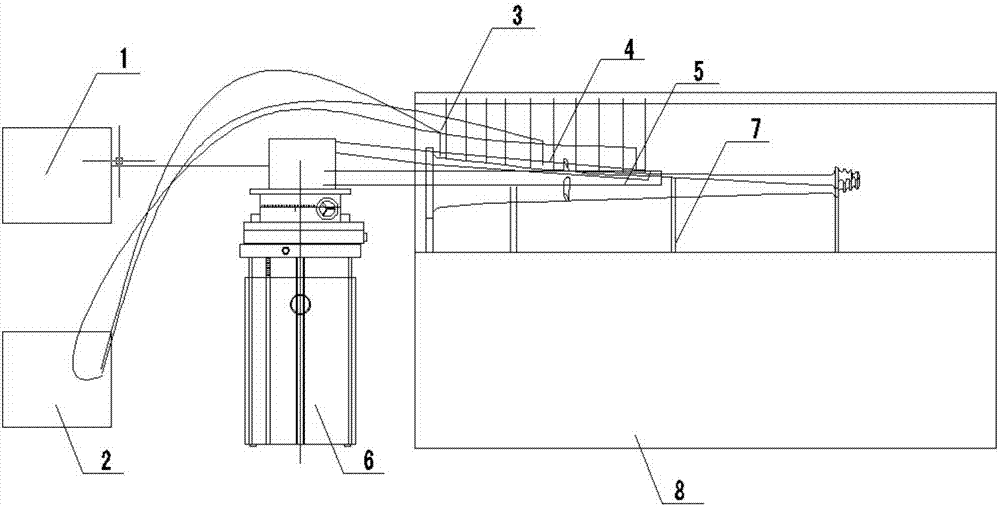

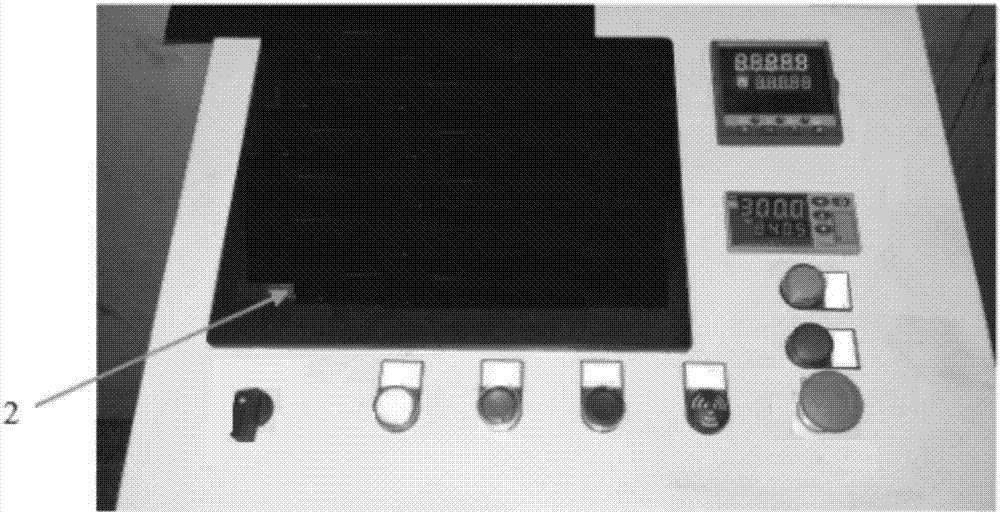

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of Stellite alloy long blade automatic high-frequency brazing system of this embodiment includes IGBT high-frequency induction heating power supply equipment 1, PLC control system 2, infrared thermometer 3, with blade profile line Inductor 4, rigid sensor bracket 5, four-axis transformer lifting and rotating platform 6, blade anti-deformation support tooling 7 and working platform tooling for brazing 8;

[0019] The rigid sensor support 5 and the transformer of the IGBT high-frequency induction heating power supply 1 are connected to the four-axis transformer lifting and rotating platform 6; the transformer of the IGBT high-frequency induction heating power supply 1 is connected with the infrared thermometer 3 and the bladed The sensor 4 of the molded line is connected with the rigid sensor bracket 5, and is used to provide power for the infrared thermometer 3, the sensor 4 with the blad...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the IGBT high-frequency induction heating power supply device adopts an IGBT high-frequency induction heating power supply device with a rated power of 25KW and an output power of 40KW.

[0021] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the infrared thermometer 3 is an infrared thermometer 3 from Kohler, Germany.

[0023] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com