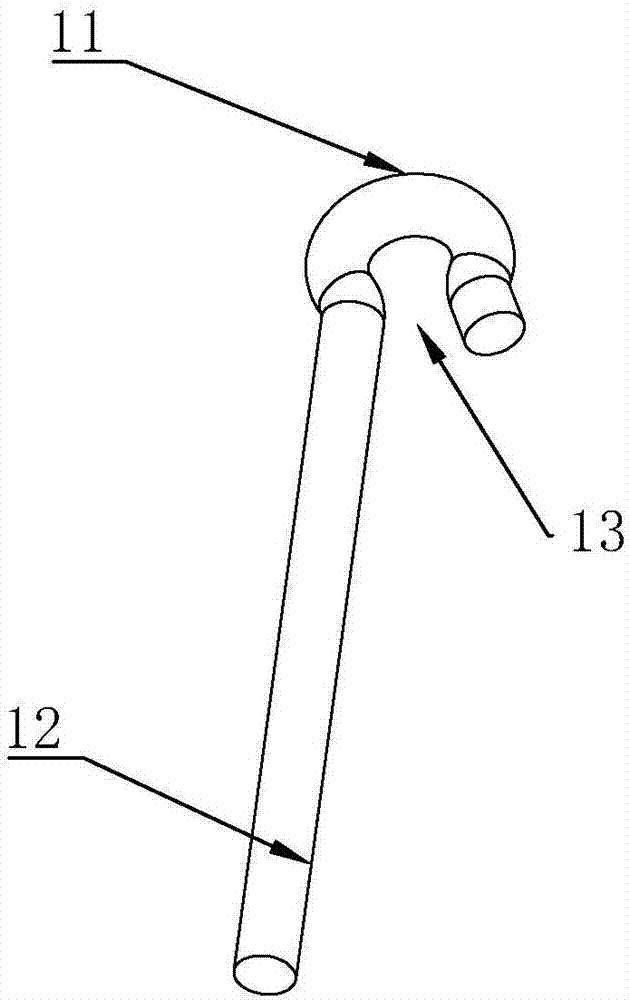

Spring hook blank vibration disc and full-automatic spring hook machining device

A technology of processing equipment and snap hooks, applied in metal processing, other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as time-consuming, incompatible with fully automatic processing, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

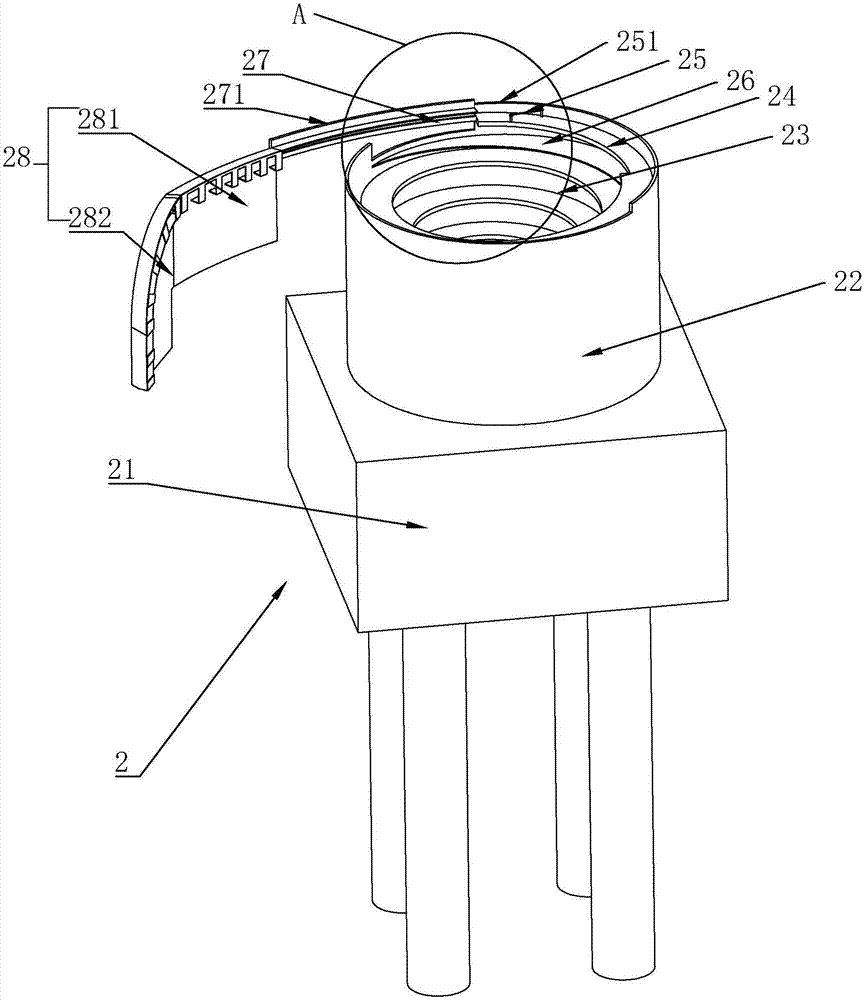

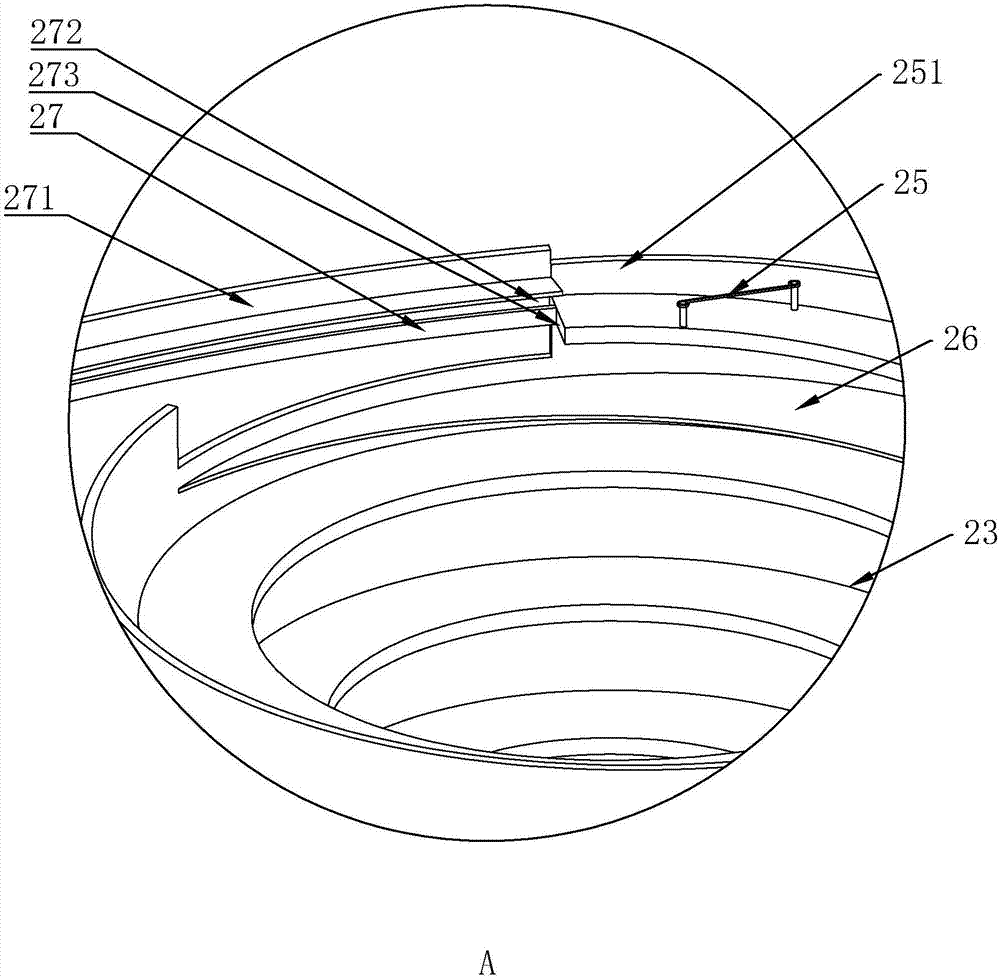

[0030] refer to Figure 2 to Figure 6 The embodiments of the vibrating plate 2 and the automatic spring hook processing equipment of the present invention will be further described.

[0031] Vibrating plate 2 is an auxiliary feeding device for automatic assembly or automatic processing machinery. It can arrange various products in an orderly manner, and cooperate with automatic assembly equipment to assemble all parts of the product into a complete product. There is a pulse electromagnet under the hopper 22 of the vibrating plate 2, which can make the hopper 22 vibrate in the vertical direction, and the hopper 22 is driven by the inclined spring to vibrate around its vertical axis. The parts in the hopper 22 rise along the spiral track due to being subjected to this vibration. After a series of orbital screening or posture changes during the ascent process, the parts can automatically enter the assembly or processing position in a unified state according to the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com