Numerical control tool rest cutting overload protection device

An overload protection, tool holder technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of time, manpower, consumption, etc., to simplify the troubleshooting process, facilitate installation, and shorten troubleshooting. and the effect of the debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

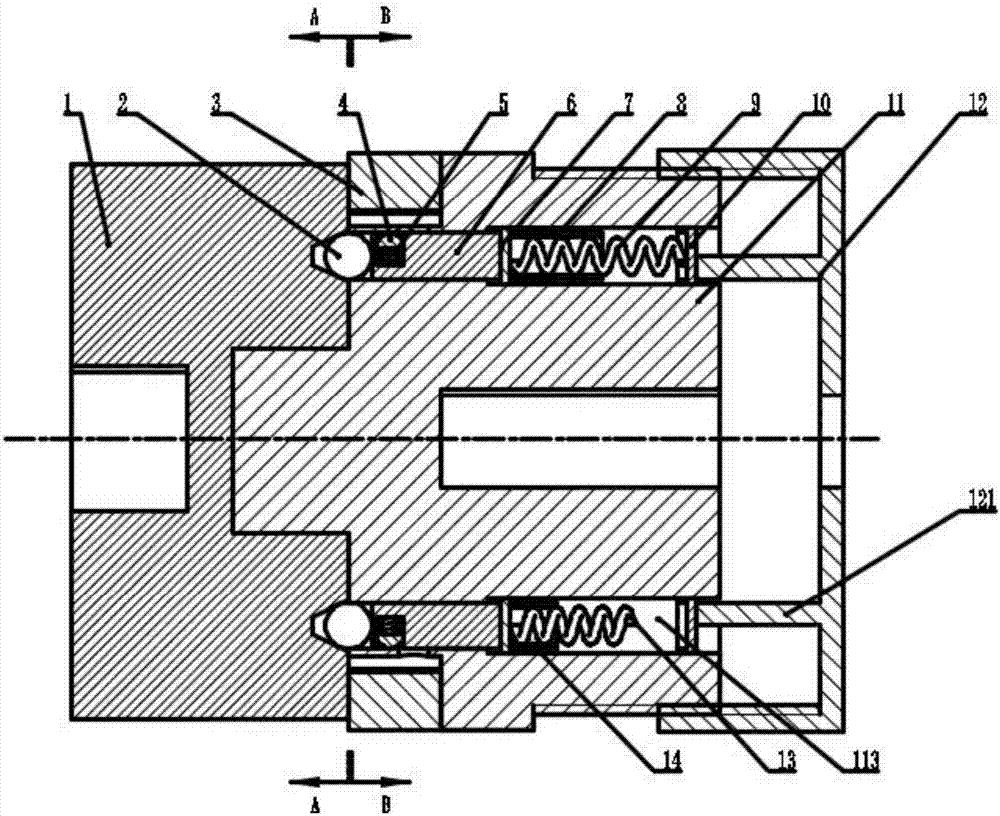

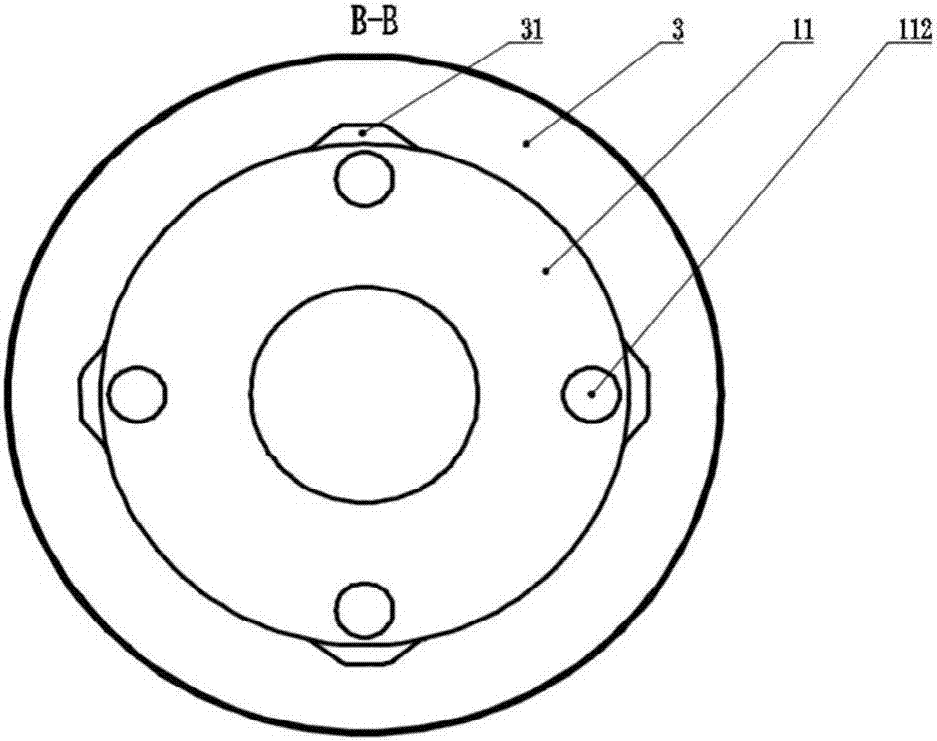

[0018] As shown in the figure, a CNC tool post cutting overload protection device includes a driving side bushing 1, a reset bushing 3, a driven side bushing 11, and an adjusting sleeve 12; one side of the driven side bushing 11 and the driving side The bushing 1 is connected, and the other side is threadedly connected with the adjusting bushing 12 , and the reset bushing 3 is sheathed on the outer side of the driven side bushing 11 close to the end of the driving side bushing 1 through the cotter pin 32 .

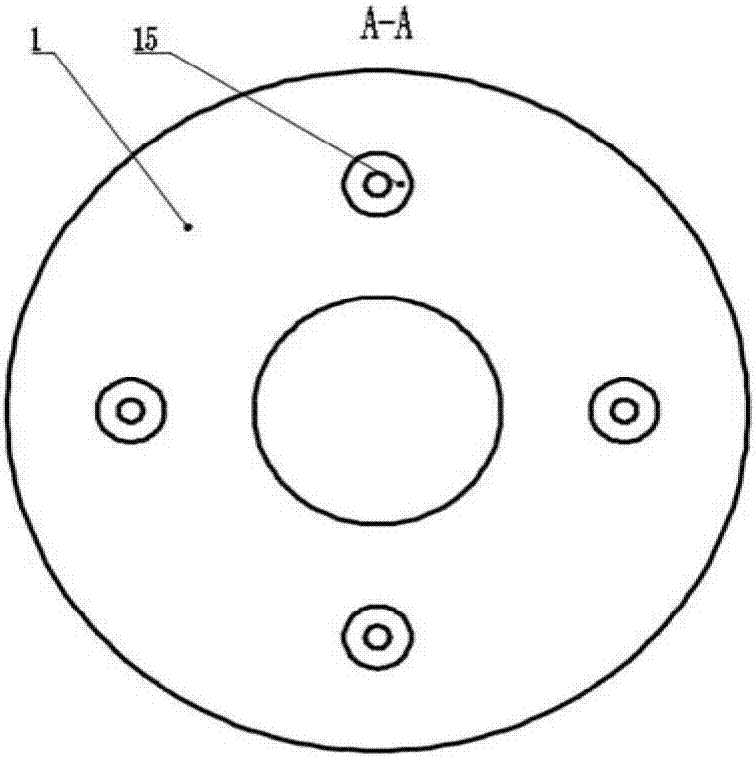

[0019] Tapered grooves 15 are evenly distributed along the circumferential direction on the end surface of the driving side bushing 1, and there are first steel ball holes 112 corresponding to the tapered grooves 15 on the driven side bushing 11, and the steel balls are placed 2 In the first steel ball hole 112, the cylindrical stopper 6 is also placed on the right side of the steel ball in the first steel ball hole 112; the driven side bushing 11 is also provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com