Planing cutter with leftward spiral cutting edge and rightward spiral cutting edge being located on same circumference

A technology of left and right spirals and blades, which is applied in special forming/shaping machines, processing machines for manufacturing flat surfaces, forming/shaping machines, etc., can solve the problems of uneven deep and shallow stripes, surface depressions, etc., and achieve force balance , stable feeding, and the effect of improving the utilization rate of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

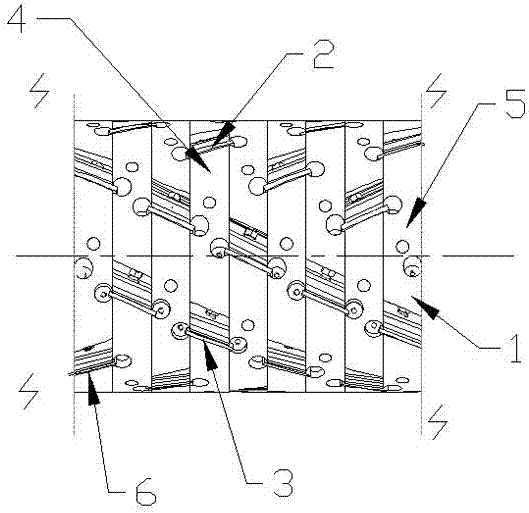

[0010] For a better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the planer that is provided with left and right spiral blades on the same circumference includes a planer 5, and the cutter body 1 of the planer 5 is provided with a plurality of sipes. A blade 6 is installed inside, and a plurality of left-handed blades 3 and right-handed blades 2 are arranged on any section of the circumference of the cutter body 1, and the left-handed blades 3 and the right-handed blades 2 are arranged at intervals, forming a shape on any section of the circumference of the cutter body 1. The left-handed and right-handed blades are arranged at intervals between the double-handed blade group 4. When the double-handed blade group 4 cuts the plate, the alternate cutting of the left and right-handed blades better reduces the risk of damage caused by the planer during the planing process. Horizontal and longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com