PNL cutting and splicing process capable of improving utilization rate of substrate

A utilization rate and substrate technology, applied in the field of PNL board cutting and assembling process, can solve the problems of poor oiling, large area and inconvenient production, and achieve the effect of improving production efficiency, enhancing market competitiveness, and high utilization rate of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

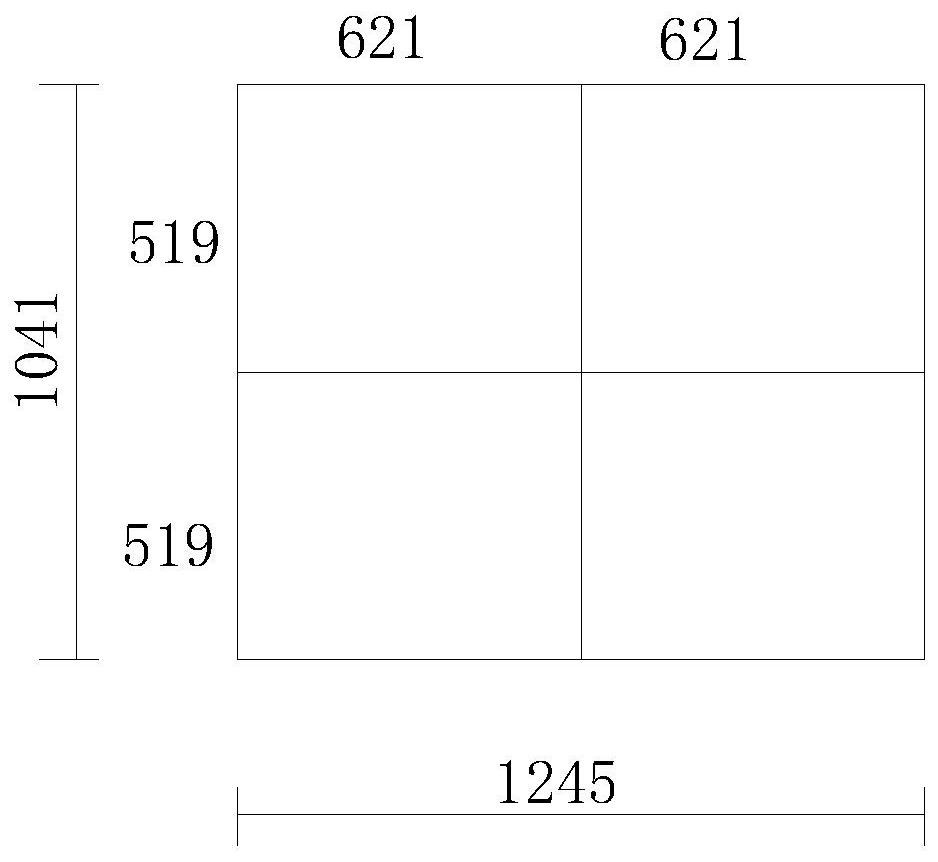

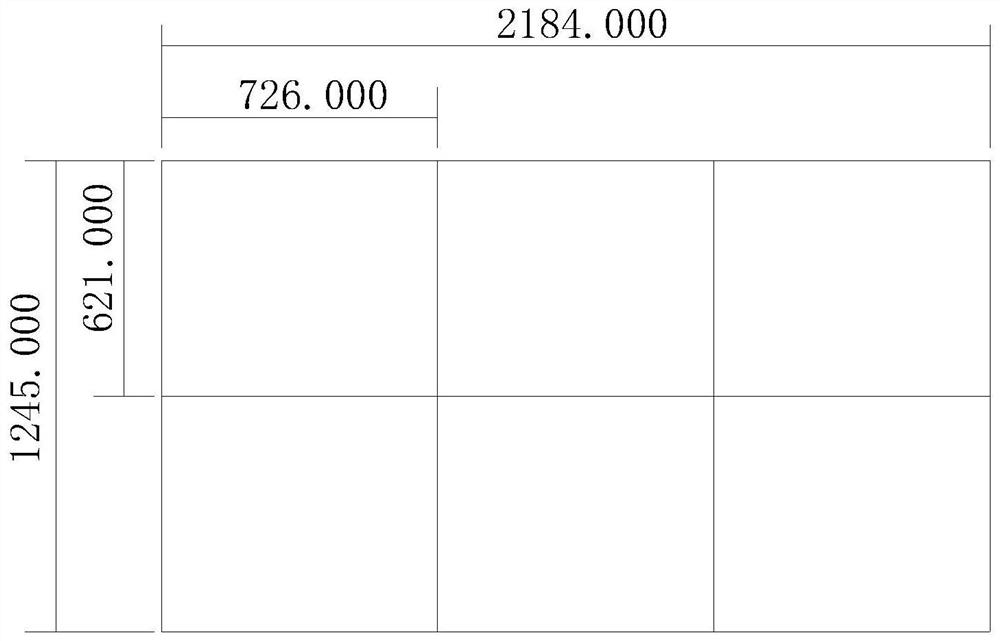

[0036] (7) if Figure 3-4 As shown, a PNL board cutting and jigsaw process for improving the substrate utilization rate of the present invention adopts a substrate size of 2184×1245mm, and uses a diamond cutting knife with a knife width of 3mm to divide the substrate size of 2184×1245mm into two rows Three rows of six A areas with a size of 726×621mm are used for material cutting; specifically, the size between two A areas with a size of 726×621mm is 3mm, and then the diamond cutting knife with a knife width of 3mm is just cut. A substrate with a size of 2184×1245mm is cut into two rows and three columns of six A regions with a size of 726×621mm.

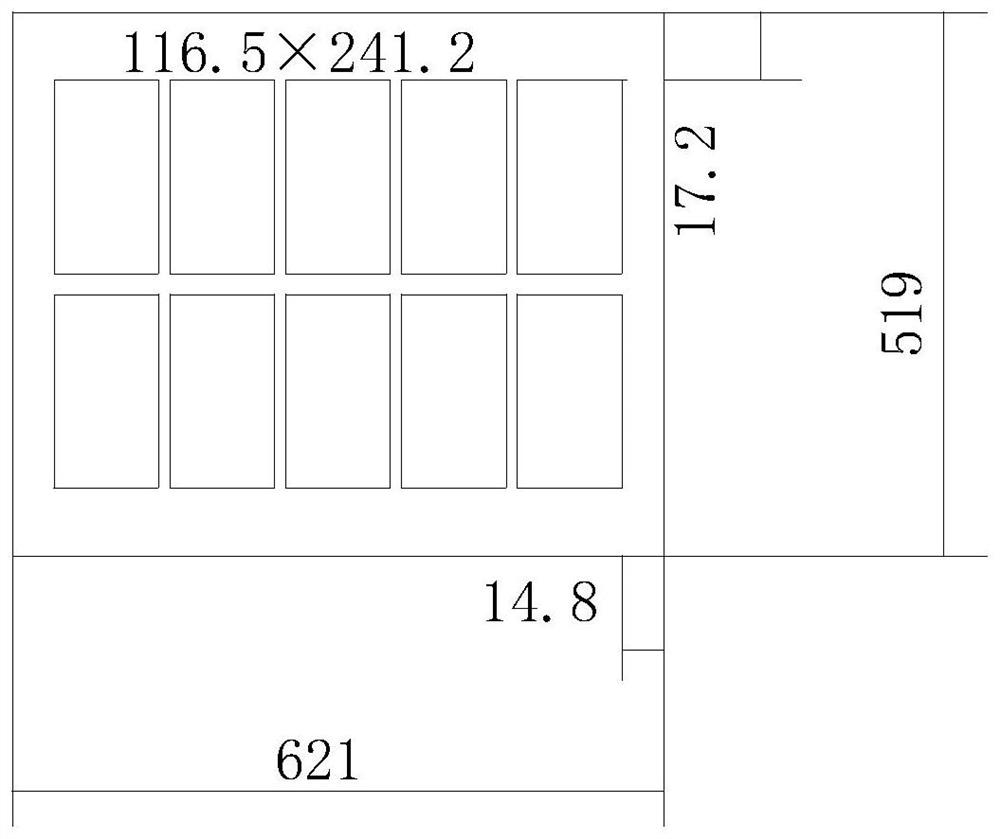

[0037] Taking the A area with a size of 726×621mm as an example, make an imposition of the A area with a size of 726×621mm, specifically, divide the A area with a size of 726×621mm into two columns and two B with a size of 621×363mm Area, and use a gong knife with a knife width of 1.5mm to divide the A area with a size of 726×621mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com