Polycarbonate preparation system

A polycarbonate and preparation system technology, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and appliances, etc., can solve problems such as increasing environmental pressure, carbon deposition in the system, reducing heat transfer effects of equipment and pipelines, etc. Achieve stable production efficiency, reduce pressure, yellowing and optimize light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

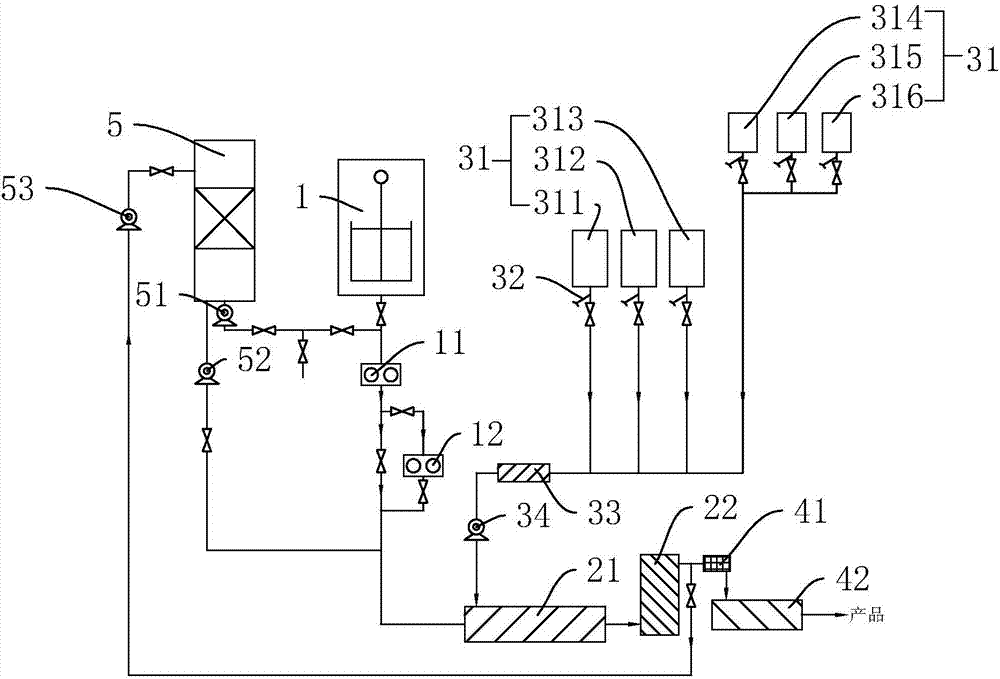

[0042] Step1 Close the valve between the melt filter 22 and the die head 41 and the valve connected between the polycondensation reactor 1 and the pipeline, open other valves between the polycondensation reactor 1 and the melt filter 22, and pass through the first booster pump 51 Press the phenol in the phenol recovery tank 5 into the pipeline, the static mixer 21, and the melt filter 22, and keep it for 10 minutes after the liquid level is stable;

[0043] Step2 transports the phenol cleaning solution dissolved with waste liquid in the pipeline to the phenol recovery tank 5 through the third booster pump 53;

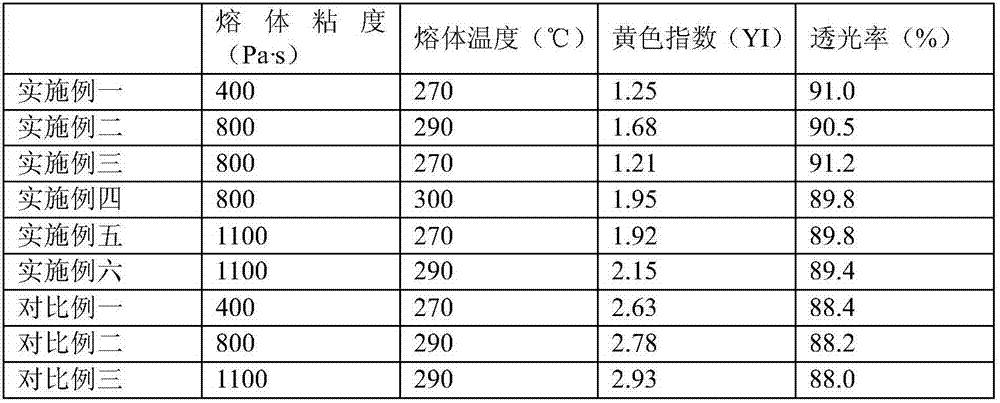

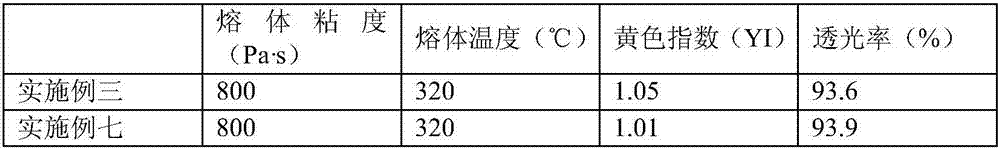

[0044] Step3 Close the valve connecting the phenol cleaning mechanism and the pipeline, set the polycondensation temperature to 270°C, preheat the polycondensation reactor 1, transport the prepolymerized product to the polycondensation reactor 1, and control the temperature at 268°C to 272°C Between, the pressure is controlled between 0.10KPa ~ 1.5Kpa, so that the prepo...

Embodiment 2

[0053] Step1 Close the valve between the melt filter 22 and the die head 41 and the valve connected between the polycondensation reactor 1 and the pipeline, open other valves between the polycondensation reactor 1 and the melt filter 22, and pass through the first booster pump 51 Press the phenol in the phenol recovery tank 5 into the pipeline, the static mixer 21, and the melt filter 22, and keep it for 10 minutes after the liquid level is stable;

[0054] Step2 transports the phenol cleaning solution dissolved with waste liquid in the pipeline to the phenol recovery tank 5 through the third booster pump 53;

[0055] Step3 Close the valve connecting the phenol cleaning mechanism and the pipeline, set the polycondensation temperature to 290°C, preheat the polycondensation reactor 1, transport the prepolymerized product to the polycondensation reactor 1, and control the temperature at 288°C to 292°C Between, the pressure is controlled between 0.1KPa ~ 1.5Kpa, so that the prepol...

Embodiment 3

[0064] Step1 Close the valve between the melt filter 22 and the die head 41 and the valve connected between the polycondensation reactor 1 and the pipeline, open other valves between the polycondensation reactor 1 and the melt filter 22, and pass through the first booster pump 51 Press the phenol in the phenol recovery tank 5 into the pipeline, the static mixer 21, and the melt filter 22, and keep it for 10 minutes after the liquid level is stable;

[0065]Step2 transports the phenol cleaning solution dissolved with waste liquid in the pipeline to the phenol recovery tank 5 through the third booster pump 53;

[0066] Step3 Close the valve connecting the phenol cleaning mechanism and the pipeline, set the polycondensation temperature to 270°C, preheat the polycondensation reactor 1, transport the prepolymerized product to the polycondensation reactor 1, and control the temperature at 268°C to 272°C Between, the pressure is controlled between 0.02KPa ~ 1.5Kpa, so that the prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com