Liquid interface forming device

A molding device and liquid interface technology, applied in the field of 3D printing, can solve the problems of small molding format, difficult to obtain oxygen permeable film, complicated control technology, etc., and achieve the effect of fast molding speed, small force, and large printing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

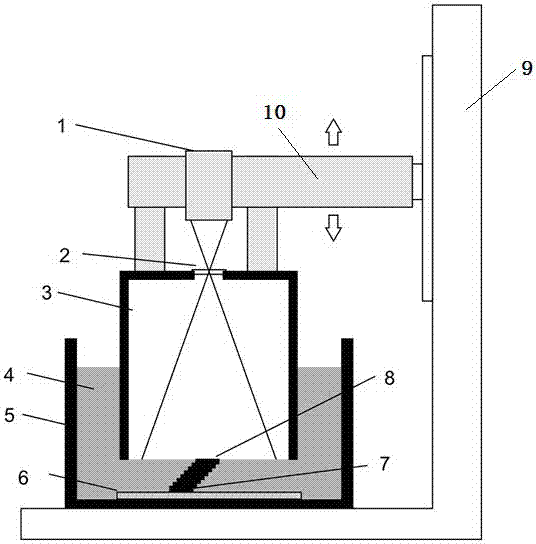

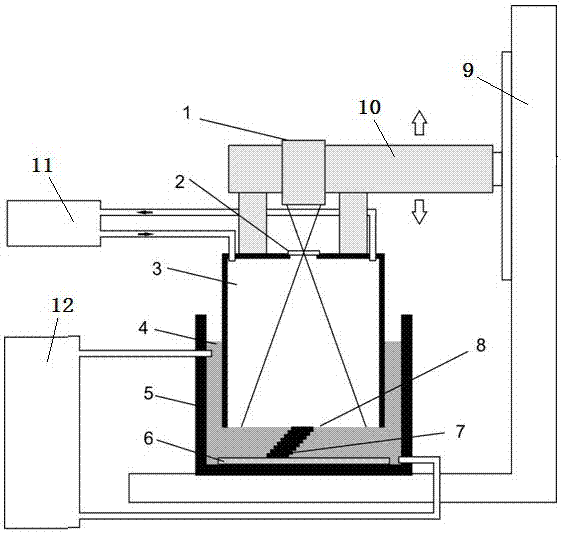

[0026] Referring to Fig. 3, on the basis of Fig. 1, the cavity 3 is connected with a first control device 11 for controlling the pressure and temperature of the gas inside, and the resin tank 5 is connected with the temperature and pressure of the liquid photosensitive resin in it. The second control device 12. The resin tank 5 is filled with liquid photosensitive resin 4, and the cavity 3 and the pattern generating device 1 stop when they move down with the first moving arm 10 and reach the molding table 6 under the control of the computer; at this time, there is only air in the sealed inflatable cavity 3 , inflate or ventilate into the sealed inflatable cavity 3 as required, when the gas-liquid interface 8 meets the requirements, the light generated by the graphic generating device 1 passes through the transparent window 2 to irradiate the gas-liquid interface 8 to cure the liquid photosensitive resin 4, and then The cavity 3 and the pattern generating device 1 move upward f...

Embodiment 2

[0028] Such as Figure 4 As shown, on the basis of Embodiment 1, a sealing ring 13 is added between the inflatable cavity 3 and the resin tank 5, so that the pressure of the gas in the sealed inflatable cavity 3 can be increased, and the pressure of the liquid photosensitive resin 4 can also be increased. pressure, so that the pressure of the gas-liquid interface 8 is greater, so that the filling speed of the liquid photosensitive resin 4 is faster. The forming speed and forming precision of the device are greatly improved.

Embodiment 3

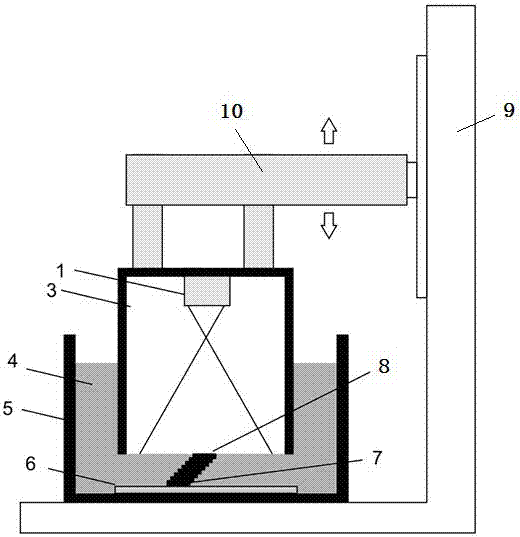

[0030] Such as Figure 5 As shown, on the basis of Embodiment 1, the inflatable cavity 3 is reduced, and the molding table 6 is made movable, and the molding table 6 is placed in the resin tank 4 through the second movable arm 14 driven by a motor and capable of moving up and down. Connect with the frame 9. When working, the forming table 6 moves downward to the set position, the cavity 3 and the pattern generating device 1 move downward to the set position, the pattern generating device 1 irradiates the gas-liquid interface 8, and the forming table 6 moves continuously with the second moving arm 14. Moving downwards for a set distance, layer by layer accumulation produces a three-dimensional shaped object 7 . The advantage of this is that the forming format can be made relatively larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com