Composite ultrasonic deposition additive manufacturing device and method

A technology of ultrasonic deposition and additive manufacturing, which is applied in the field of additive manufacturing, can solve the problems of poor comprehensive mechanical properties of parts, poor dimensional accuracy of parts, and limited types of forming materials, and achieve high forming accuracy, simple forming process and low manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

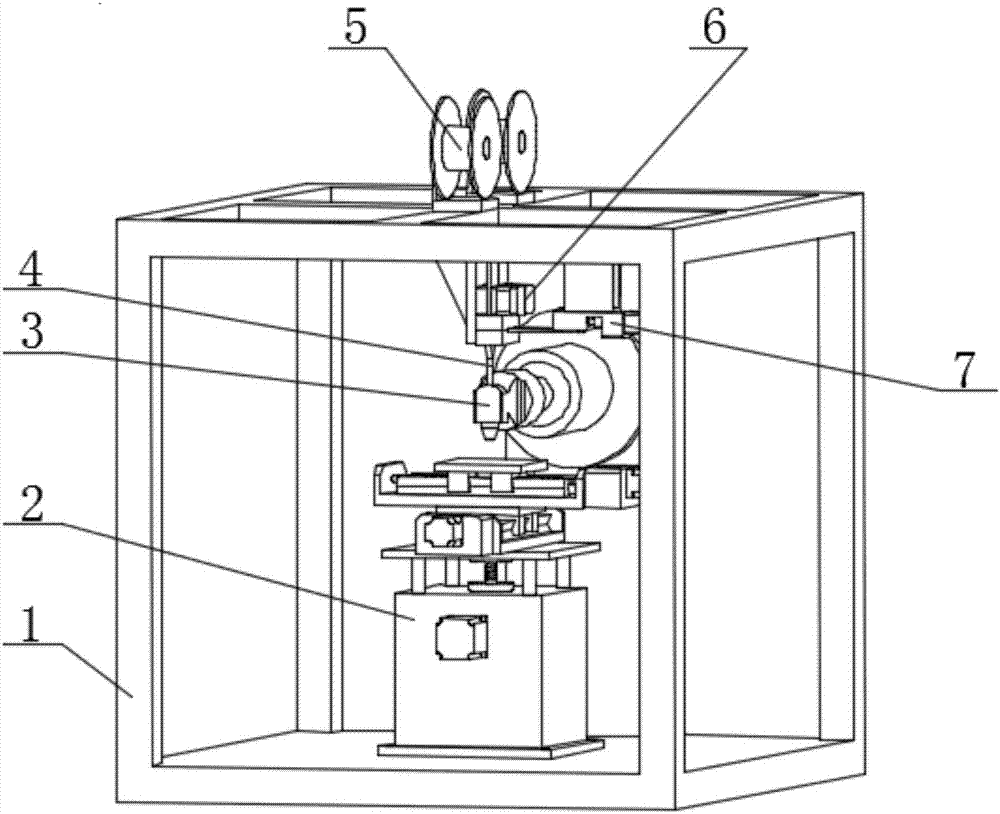

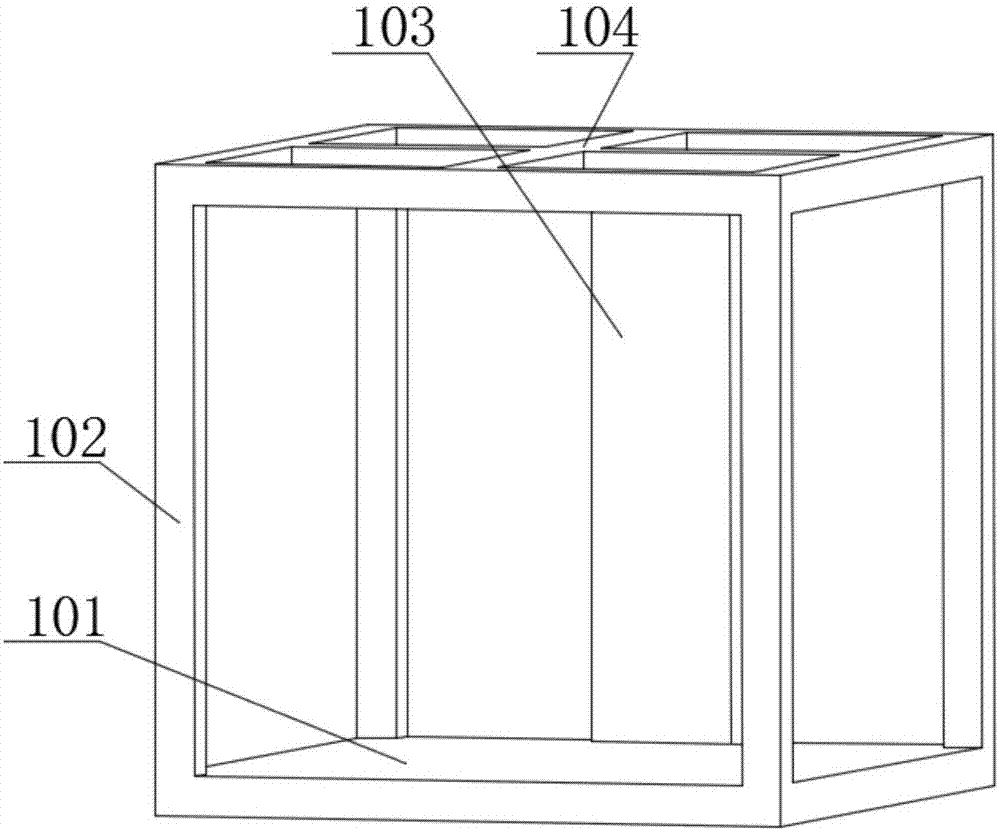

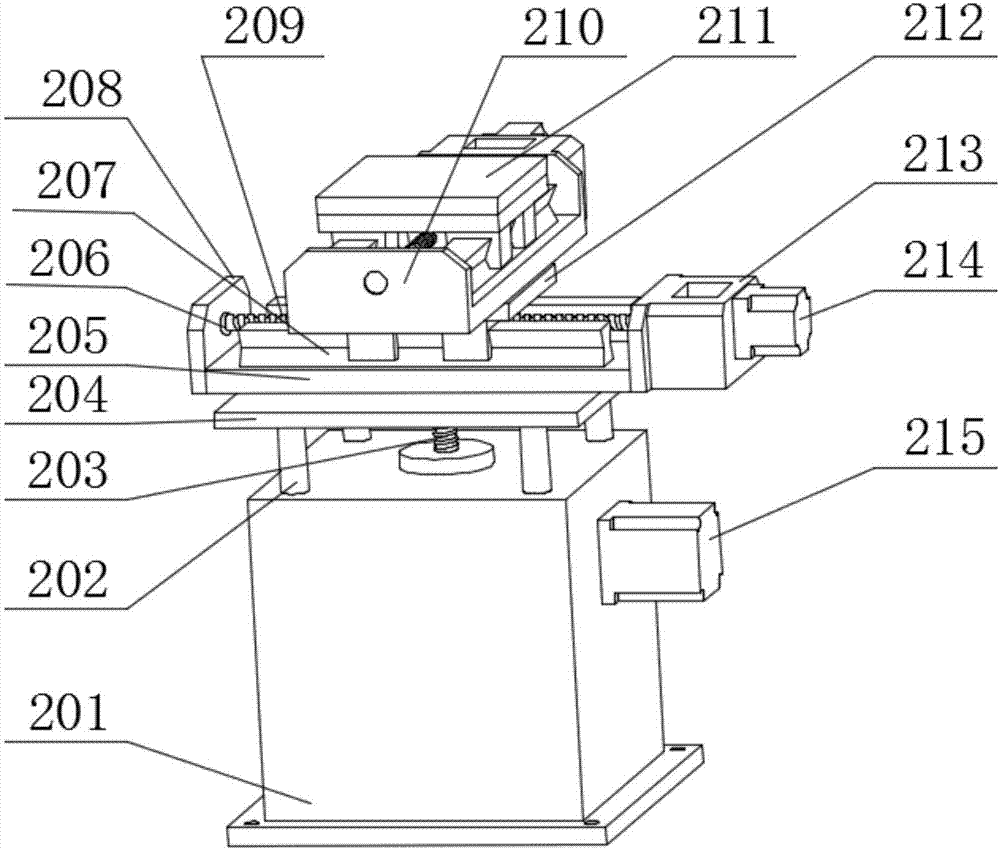

[0032] A composite material ultrasonic deposition additive manufacturing device, including a frame 1, a three-axis motion system 2, an ultrasonic deposition printing head 3, a wire guide tube 4, a material roller 5, a wire feeding device 6 and a wire cutting device 7, such as figure 1As shown, the three-axis motion system 2 is fixed in the frame 1 and located above its bottom plate 101, and the ultrasonic deposition printing head 3 is located above the three-axis motion system 2 and fixed on the support plate 103. The wire guide tube 4 is located between the ultrasonic deposition printing head 3 and the wire feeding device 6 and is connected to the two, and the wire cutting device 7 is located above the ultrasonic deposition printing head 3 and fixed on the cross beam at the top of the frame 1 104, the wire feeding device 6 is located in the frame 1 and fixed on the cross beam 104 on the top thereof, and the material roller 5 is located outside the frame 1 and fixed on the cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com