Power-off system for battery pack of electric car

A technology of electric vehicle and battery management system, applied in the field of electric vehicle battery pack power-off system, can solve the problem that the high-voltage control and protection part of the application circuit structure is not perfect, can not achieve high-voltage electrical signal and low-voltage electrical signal isolation, hardware damage detection and other problems, to achieve the effect of avoiding the danger of electric shock, simple structure and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

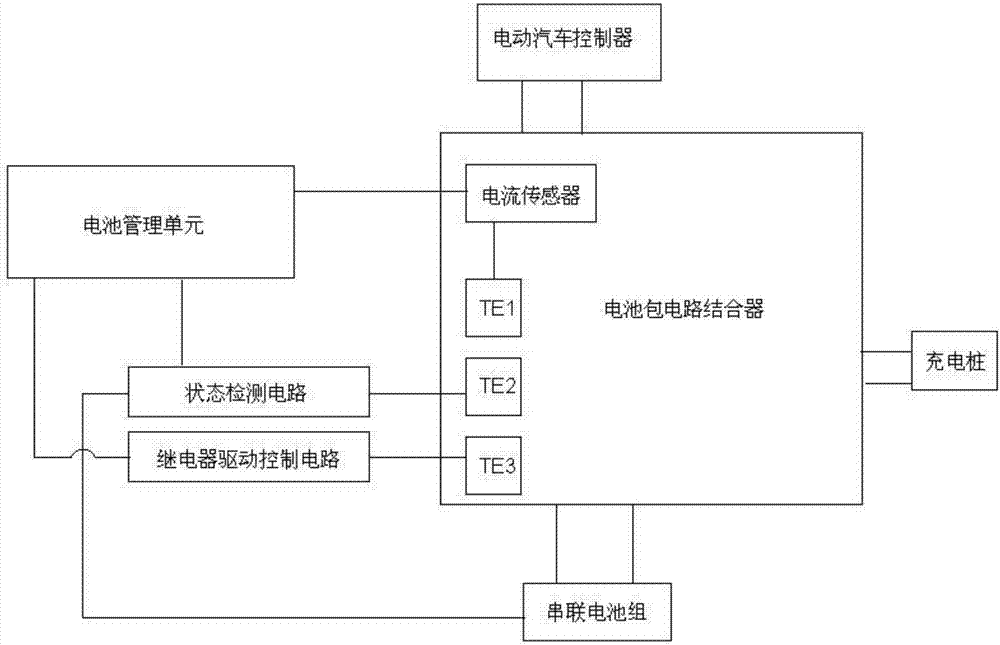

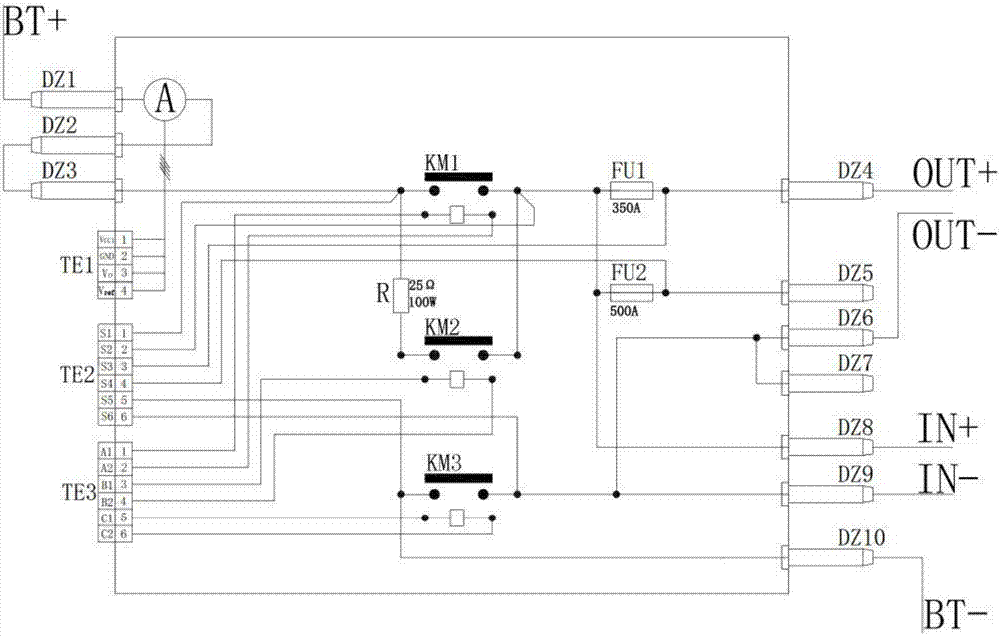

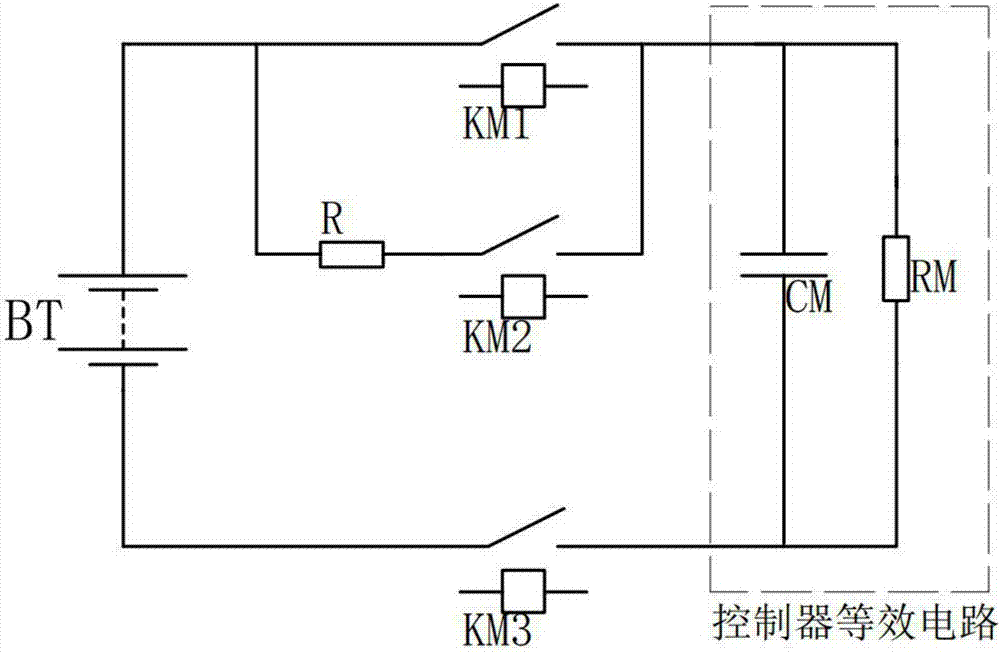

[0030] Such as figure 1 As shown, an electric vehicle battery pack power-off system is respectively connected with the battery management system inside the electric vehicle, the electric vehicle controller, the series battery pack and the charging pile outside the electric vehicle; it includes a battery pack circuit coupler, a relay drive control Circuit and state detection circuit; battery pack circuit combiner includes battery pack positive and negative circuits and battery pack pre-charging circuit, battery pack positive and negative circuits and battery pack pre-charging circuit are connected in series with relays; relay drive control circuit and battery pack circuit combiner Electrical connection, to control the on-off of the relay in the battery pack circuit coupler; the state detection circuit is electrically connected to the battery pack circuit coupler, to detect the potential of the connection point between the battery pack circuit coupler and the electric vehicle con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com