Buffer device for pneumatic sample conveying system

A technology of pneumatic conveying and buffering device, used in conveyors, transportation and packaging, etc., can solve friction and collision force damage to pneumatic transmission pipes and samples, shorten the life of pneumatic transmission pipes and samples, change the physical properties of samples and test accuracy, etc. problems, to achieve the effect of promoting efficient operation, improving practicability and applicability, and ensuring normal development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

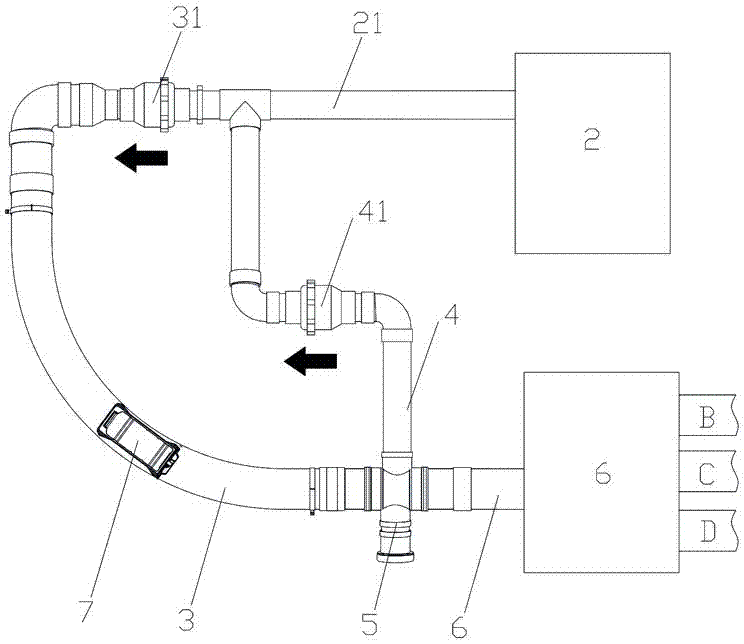

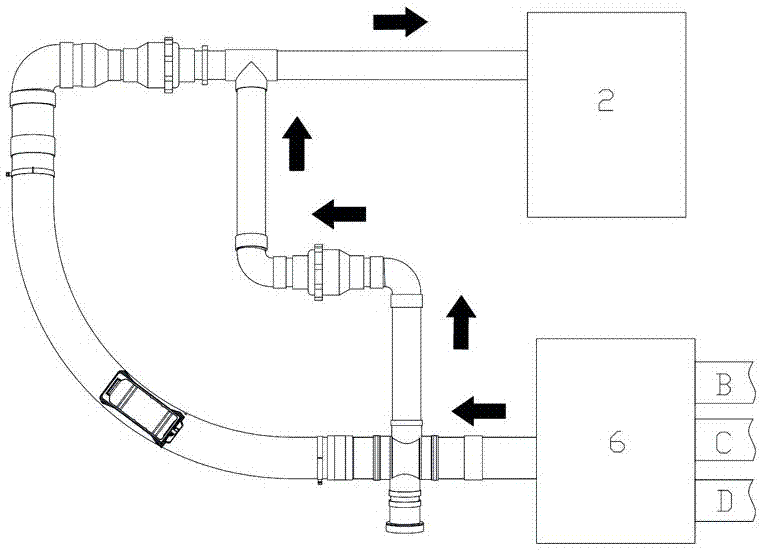

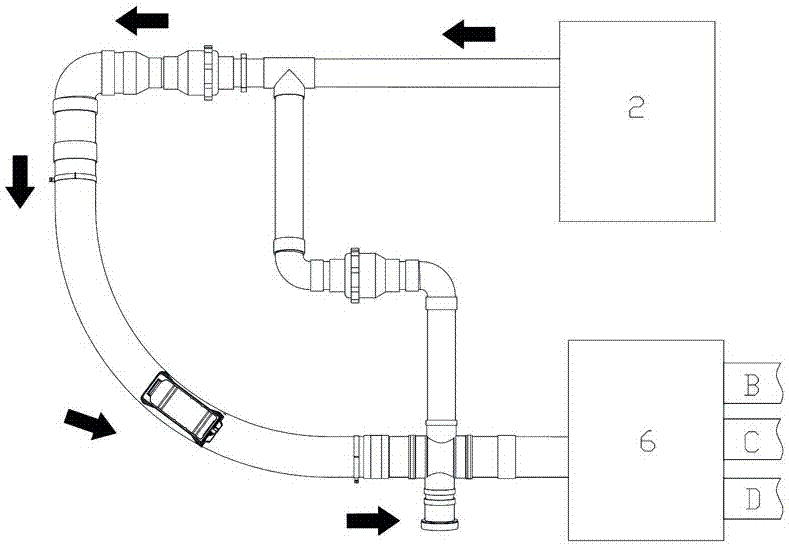

[0026] Such as Figure 1 to Figure 3 As shown, the present invention provides a buffer device for a sample pneumatic conveying system, which is arranged between the main conveying pipeline 1 and the power cabinet 2 of the pneumatic conveying system, including connecting the main conveying pipeline 1 and the power cabinet in parallel The buffer pipeline 3 and the branch pipeline 4 between the power pipeline 21 of 2. The buffer pipeline 3 is used for buffering the sample bottle 7, and the buffer pipeline 3 is provided with a forward check valve 31, so that the gas blown out by the power cabinet 2 can only flow into the buffer pipeline 3 through the forward check valve 31; The pipeline 4 is only used for adjustment, and the sample bottle 7 will not be passed into the branch pipeline 4. The branch pipeline 4 is provided with a reverse check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com